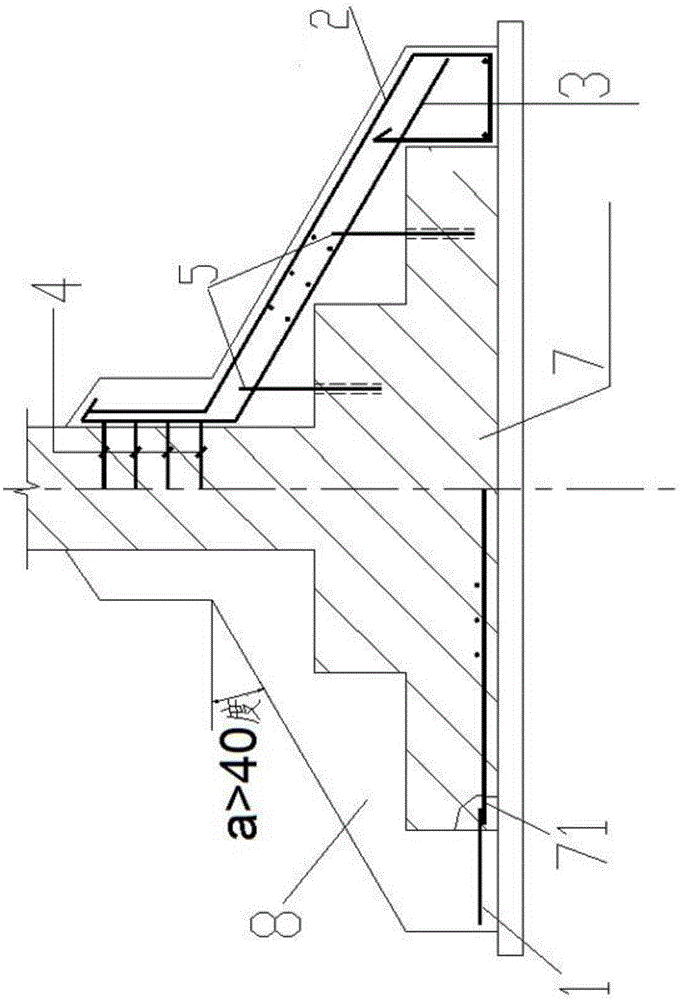

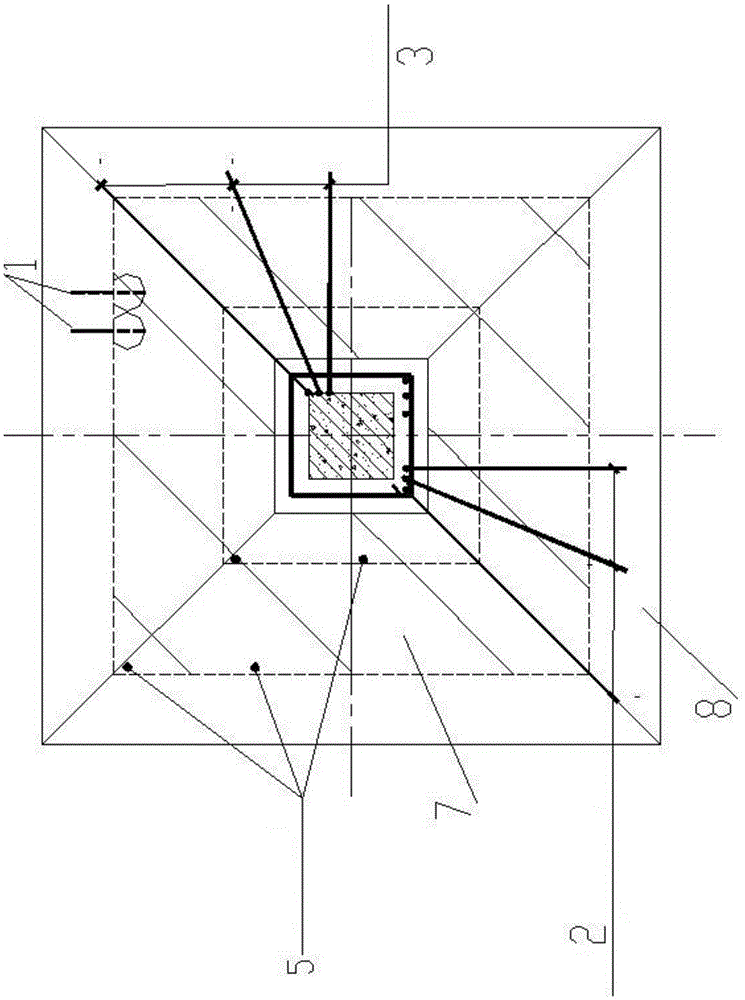

Foundation reinforcement method and its structure

A foundation reinforcement and foundation technology, applied in the field of casing reinforcement and its construction, can solve the problems of huge construction workload and many limitations, and achieve the effect of reduced construction workload, simple technical measures, and strong effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

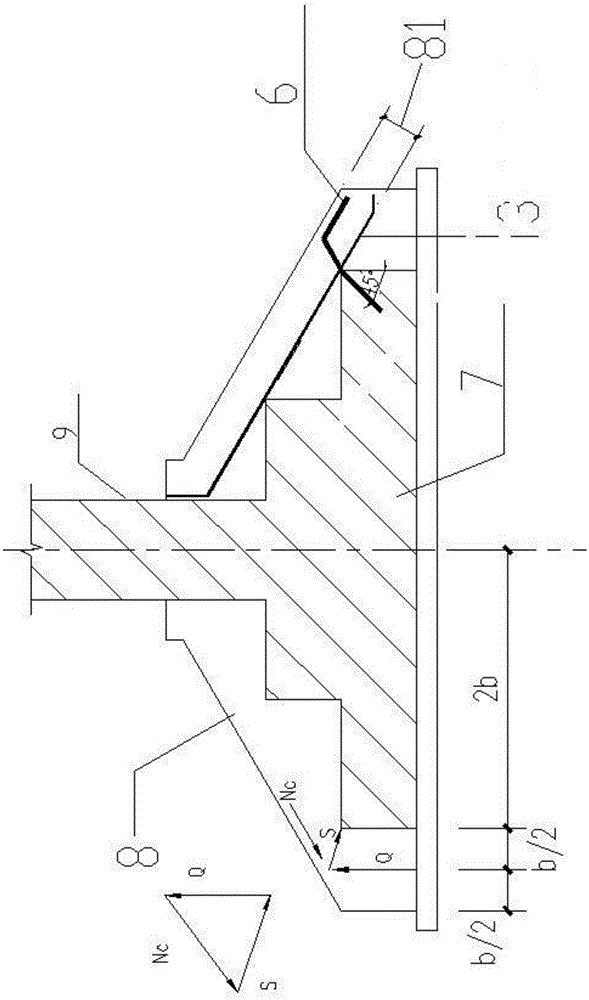

Embodiment 1

[0032] A number of sixth steel bars 6 are arranged at intervals around the outer corners of the original foundation. One end of the sixth steel bars 6 is fixed to the outer corner of the original foundation, and the other end is fixed in the enclosure along with the construction pouring, which is used for fixed connection between the original foundation and the enclosure. At the same time, add a fulcrum for the third steel bar 3. In this way, the present invention can efficiently and reliably realize the connection between the original foundation and the cast-in-situ concrete enclosure only by using the bar planting technology (which is a mature conventional technology in the art). By arranging the sixth steel bar 6, a balanced tension S is added to the stress system, which fully exerts the role of the space of the 8 enclosures, and immediately shows the effect of "four or two to pull a thousand catties". Since the third steel bar 3 "accidentally" obtained a fulcrum, two force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com