The splitter of high-efficiency atomizing sprayer in cotton field

A technology of sprayer and liner, which is applied in the direction of catching or killing insects, application, animal husbandry, etc. It can solve the problems of comprehensiveness, too fast cotton closing, uneven application of pesticides, etc., so as to reduce scraping resistance and ensure The effect of spraying, the effect of improving the effect of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

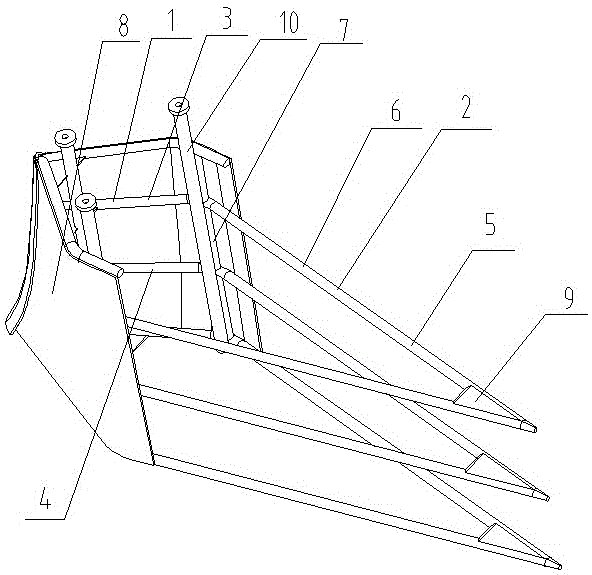

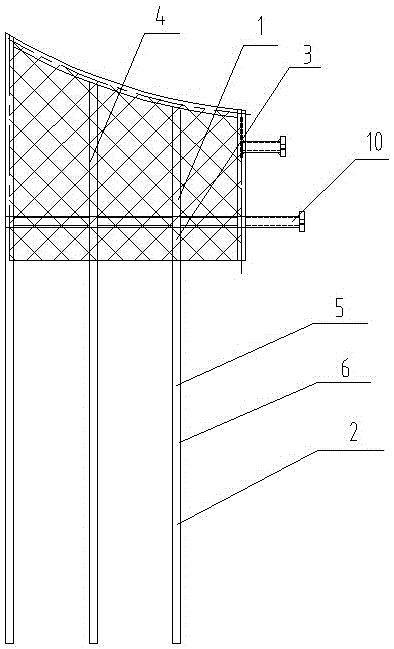

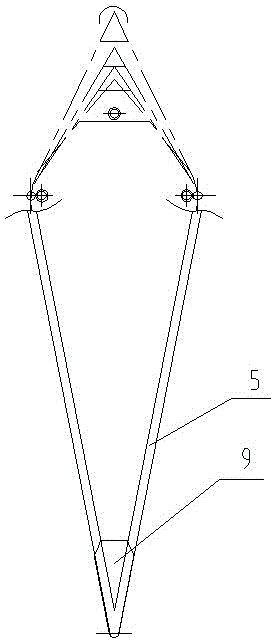

[0020] Such as figure 1 , 2 , 3, 4, 5, and 6, the distributor of the cotton field high-efficiency atomizing sprayer includes a front guide assembly 1 and a rear buffer guide assembly 2. The front guide assembly 1 includes three layers consisting of two The guide rods 3 form a V-shaped front guide frame 4, the front guide frames 4 of each layer are parallel to each other, and each front guide frame 4 is respectively fixed on the front end of the rear buffer guide assembly 2. The rear buffer guide assembly 2 includes three layers of V-shaped rear buffer guide frames 6 composed of two guide rods 5, and the rear buffer guide frames 6 of each layer are respectively fixedly connected with the front guide frames 4 of each layer in front of them. The rear buffer guide frame 6 and the front guide frame 4 form a rhombus, and support ribs 7 are respectively arranged between the adjacent two-layer rear buffer guide frame 6 and the front guide frame 4, and the two ends of each support rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com