Motor vehicle vertical brake lever for preventing brake shoe eccentric-wear

A technology for motor vehicles and vertical rods, which is applied in the direction of railway braking systems, brakes with brakes, and brake wear compensation mechanisms, etc., and can solve problems such as abnormal wear of locomotive brake shoes, increased manpower and material costs, and short transportation distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

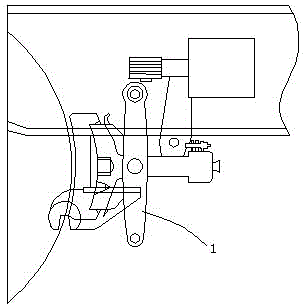

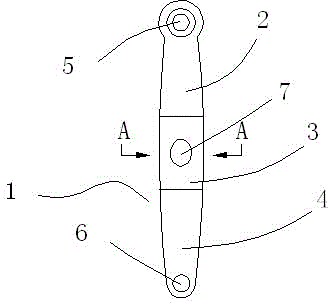

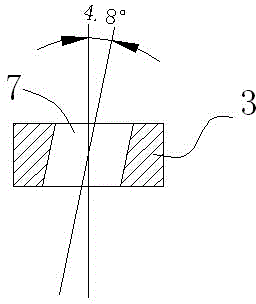

[0013] Such as figure 2 , image 3 , Figure 4 As shown, a motor vehicle brake vertical bar for preventing brake shoe eccentric wear includes a vertical bar body 1, and the vertical bar body is divided into an upper fixed end 2, a middle connecting end 3 and a lower fixed end 4 from top to bottom. , the middle connecting end 3 is welded with the upper fixing end 2 and the lower fixing end 4, the upper fixing end 2 is provided with an upper fixing hole 5, the lower fixing end 4 is provided with a lower fixing hole 6, and the upper fixing hole 5 and the lower fixing hole 6 are arranged along the The radial direction is located on the same horizontal plane, and the axes of the two holes are parallel to each other; in the middle of the connecting end 3 of the middle part, there is a revocation hole 7 for fixing the brake shoe holder, and the axis of the revocation hole 7 is connected with the axes of the upper fixing hole 5 and the lower fixing hole 6. Angle, the angle is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com