Manual underwater dumping device

A manual and handle technology, which is applied to underwater ships, underwater operating equipment, motor vehicles, etc., can solve the problems of equipment and personnel damage, the instantaneous impact of explosive bolts, etc., and achieve reliable dumping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

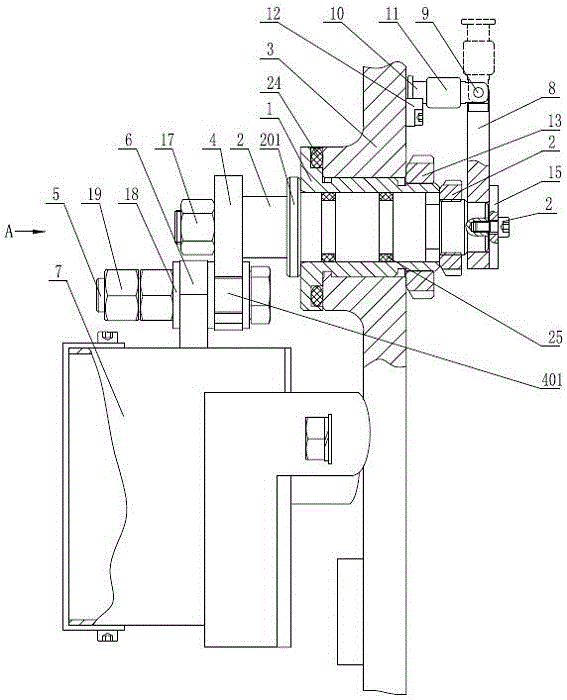

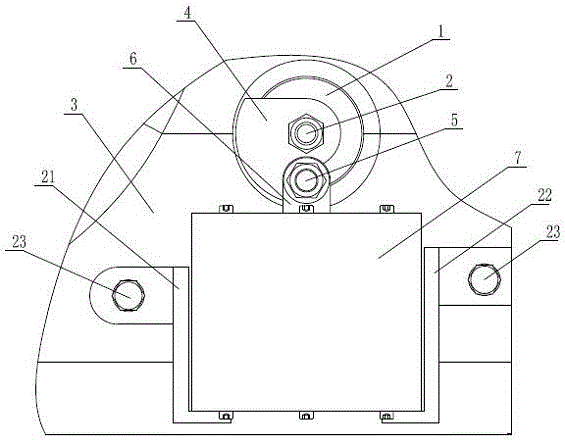

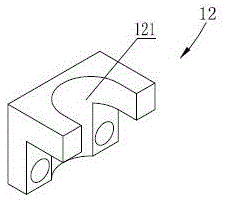

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0032] See figure 1 , the present invention includes a sleeve 1 and a pin shaft 2, the sleeve 1 passes through the cabin wall of the underwater manned equipment cabin 3, and is locked on the cabin wall, the pin shaft 2 passes through the sleeve 1 and can be Rotationally supported in the sleeve 1, the sleeve 1 and the underwater manned equipment cabin 3, and between the sleeve 1 and the pin shaft 2 are all watertight connections; the pin shaft 2 is located on the outside of the underwater manned equipment cabin 3 There is a hook 4 on the shaft section, the hook 4 is locked on the pin shaft 2, the bolt 5 is passed through the hook part 401 with a gap in the hook 4, the lifting lug 6 is set on the bolt 5, the hook 4 and the hanging The lugs 6 are all axially limited on the bolts 5, and the lugs 6 are fixed on the top of the ballast tank 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com