Container and manufacturing method

A manufacturing method and container technology, applied in the direction of bottle/container cap, capping the container tightly with the cap, cap, etc., can solve the problems of reducing the airtightness of the container, affecting the safety of the drink inside, and easy penetration of chemical fungicides, etc., to achieve improvement The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

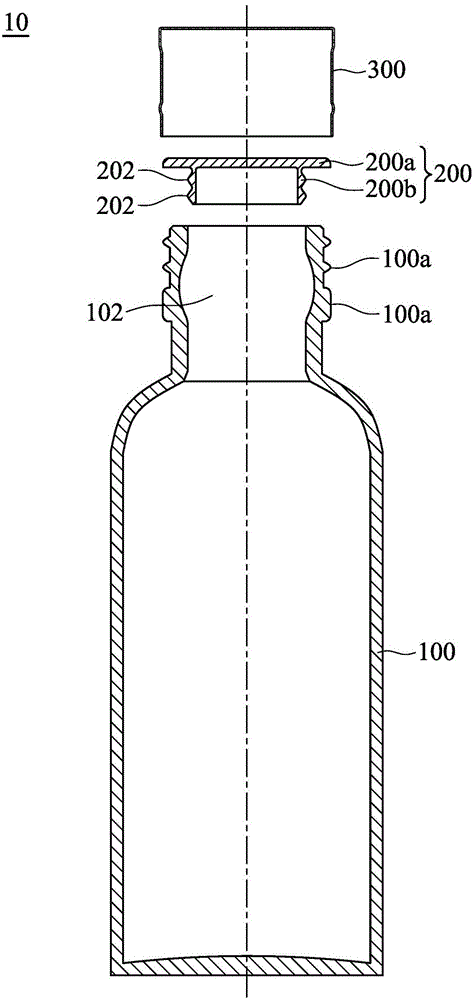

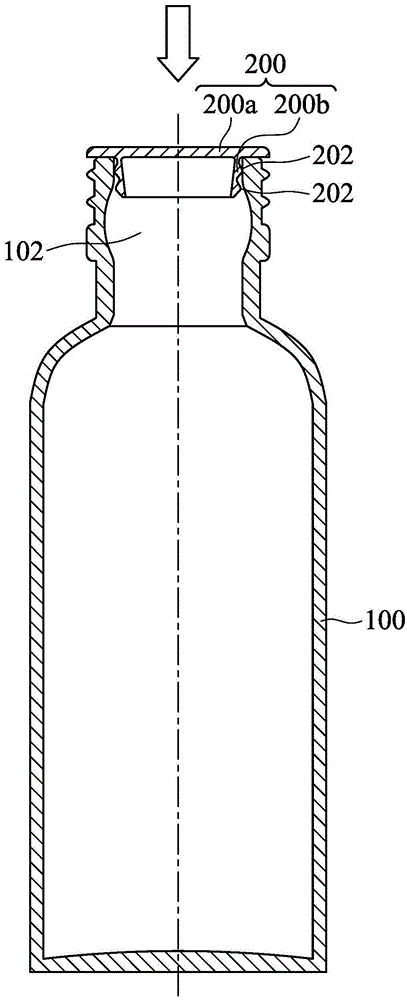

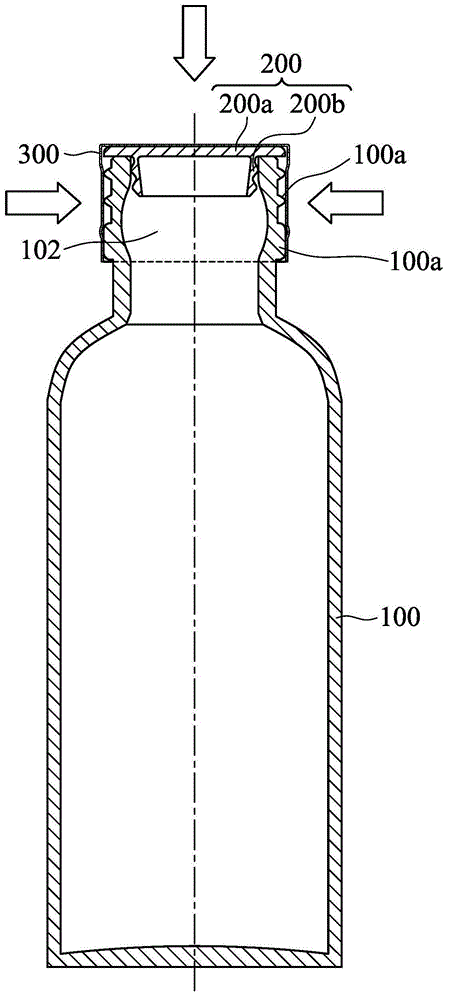

[0032] Please see first figure 1 As shown (all the views described below are shown as cross-sectional views), the container 10 according to an embodiment of the present invention can be used for filling beverages, and mainly includes a body 100 , an inner plug 200 and a cover 300 .

[0033] Wherein, the body 100 is a bottle made of glass, and has an opening 102 and a first thread structure 100 a located outside the body 100 , and the first thread structure 100 a roughly corresponds to the position of the opening 102 . The inner plug 200 can be made of polypropylene (PP) and has a π-shaped cross-section structure, wherein the inner plug 200 is formed by connecting a disc portion 200a with a larger diameter to a thin cylindrical shell portion 200b with a smaller diameter. composition. In this embodiment, the inner plug 200 also has at least one protruding portion 202 (two protruding portions 202 are included in this embodiment), which surrounds the outer side of the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com