Circular anti-leakage reinforced concrete pool

A technology for reinforced concrete and pools, which is applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of poor anti-cracking effect of pool walls, complex reinforced structure, and large amount of use. Effect of age, good cracks and deformation phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

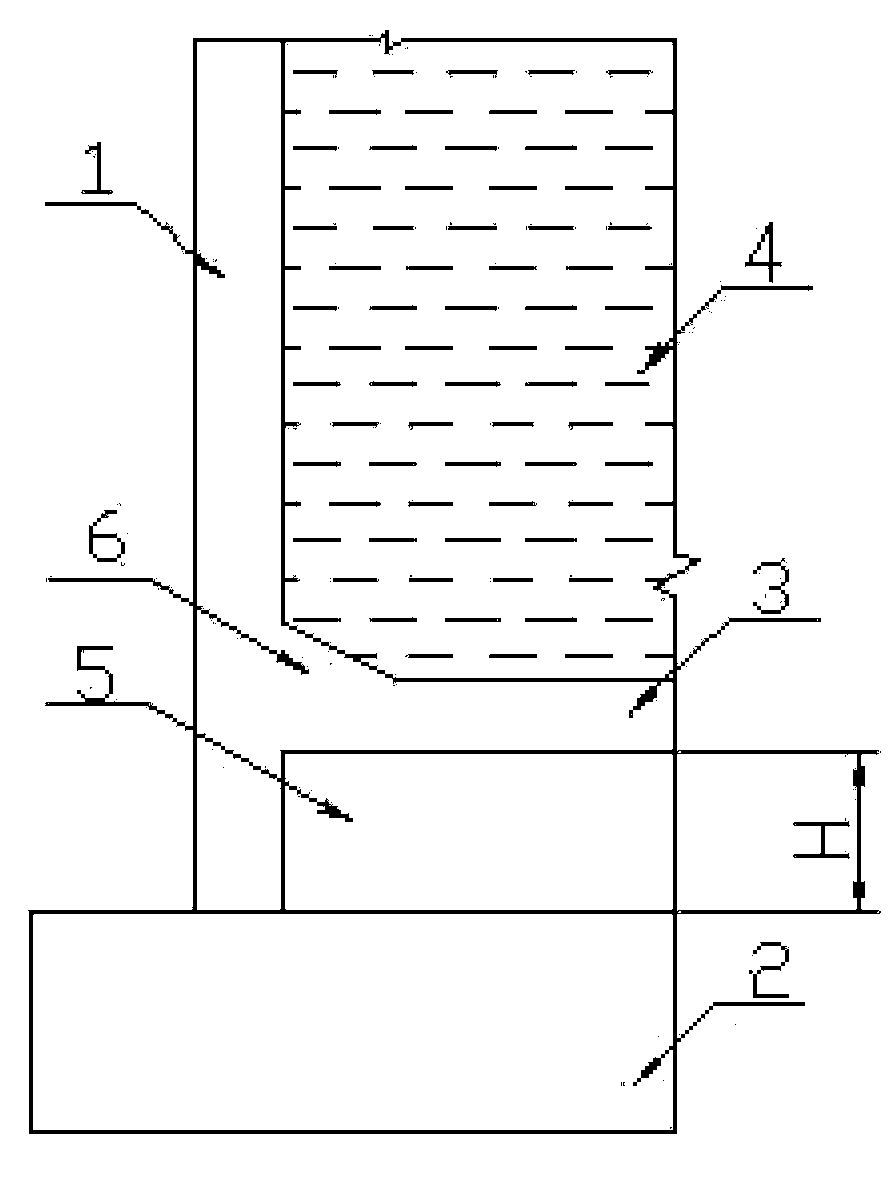

[0018] refer to figure 1 The anti-seepage type reinforced concrete circular pool involved in this embodiment includes a reinforced concrete pool, and the reinforced concrete pool is surrounded by a cylindrical pool wall 1 and a foundation floor 2, and a partition is set above the foundation floor 2. The reinforced concrete pool 1 is divided into a water storage area 4 and a non-water storage area 5 through the interlayer bottom plate 3, forming a double-bottom reinforced concrete structure, so that the influence of temperature changes on the pool is concentrated on the foundation bottom plate 2 and the partition. On the pool wall between the bottom plates 3, to reduce the temperature stress of the water storage area 4.

[0019] In the example:

[0020] The non-water storage area 5 is enclosed by the foundation floor 2, the interlayer floor 3 and the cylindrical pool wall 1, forming a spatial structure that bears the temperature and tensile stress of the reinforced concrete ci...

specific Embodiment 2

[0022] The feature of this embodiment 2 is: the non-water storage area 5 is an open space structure. All the other are with specific embodiment 1.

specific Embodiment 3

[0023] The feature of this embodiment 3 is: the interlayer bottom plate (3) is set within 1 / 6 of the height of the cylindrical pool wall (1). All the other are with specific embodiment 1 or specific embodiment 2.

[0024] The present invention adopts the double-layer bottom plate structure of the base bottom plate and the interlayer bottom plate, and the distance between the interlayer bottom plate and the foundation bottom plate is about 1-2m. Through tests and analysis, the reinforced concrete with double-layer bottom plate according to the present invention is adopted. For pools, the impact of temperature changes on the pool is mainly concentrated between the double bottom plates, and the temperature stress in the water storage area is significantly reduced, solving or avoiding the problem of leakage in the water storage area of the pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com