Double-clamping mechanism

A technology of clamping mechanism and clamping arm, which is applied in the direction of clamping, workpiece clamping device, metal processing machinery parts, etc., can solve the problems of high manufacturing cost and complex structure, and achieve low manufacturing cost, simple overall structure and flexible action reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

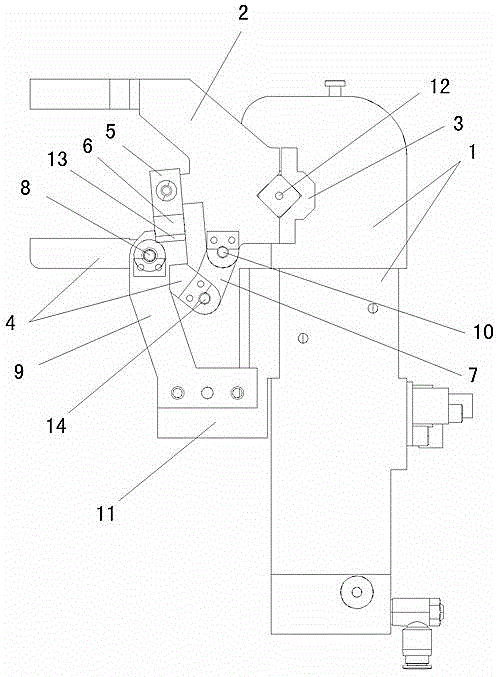

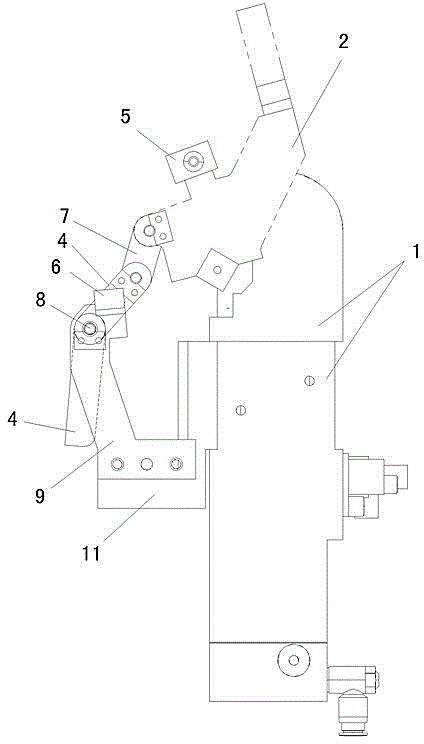

[0008] Such as figure 1 , 2 As shown: 1 is a rotary cylinder, the output end 12 of the rotary cylinder 1 is connected with the upper clamping arm 2 through the connecting piece 3, and when the output end rotates, the upper clamping arm 2 can be driven to rotate. The lower clamp arm 4 is matched with the upper clamp arm 2 . The lower clamp arm 4 is rotatably connected to the support arm 9 by the rotating shaft 8, the support arm 9 is fixedly connected with the support base 11 by bolts, and the support base 11 is relatively fixed with the cylinder body of the cylinder 1. A connecting rod 7 is connected between the rear ends of the upper clamping arm 2 and the lower clamping arm 4, and the two ends of the connecting rod 7 are connected to the lower clamping arm 4 and the upper clamping arm 2 through the first bearing pin 14 and the second bearing pin 10 respectively. active connection. The front inner workpiece clamping surfaces of the upper clamp arm 2 and the lower clamp arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com