An Axisymmetric Converging and Expanding Nozzle with Single Action System

A single-acting, axisymmetric technology, applied in the field of engine nozzles and aero-engine nozzles, can solve the problems of complex control laws, cannot be blocked by front-end hot end components, uncontrollable, etc., and achieve simple control laws, good stealth function, The effect of high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

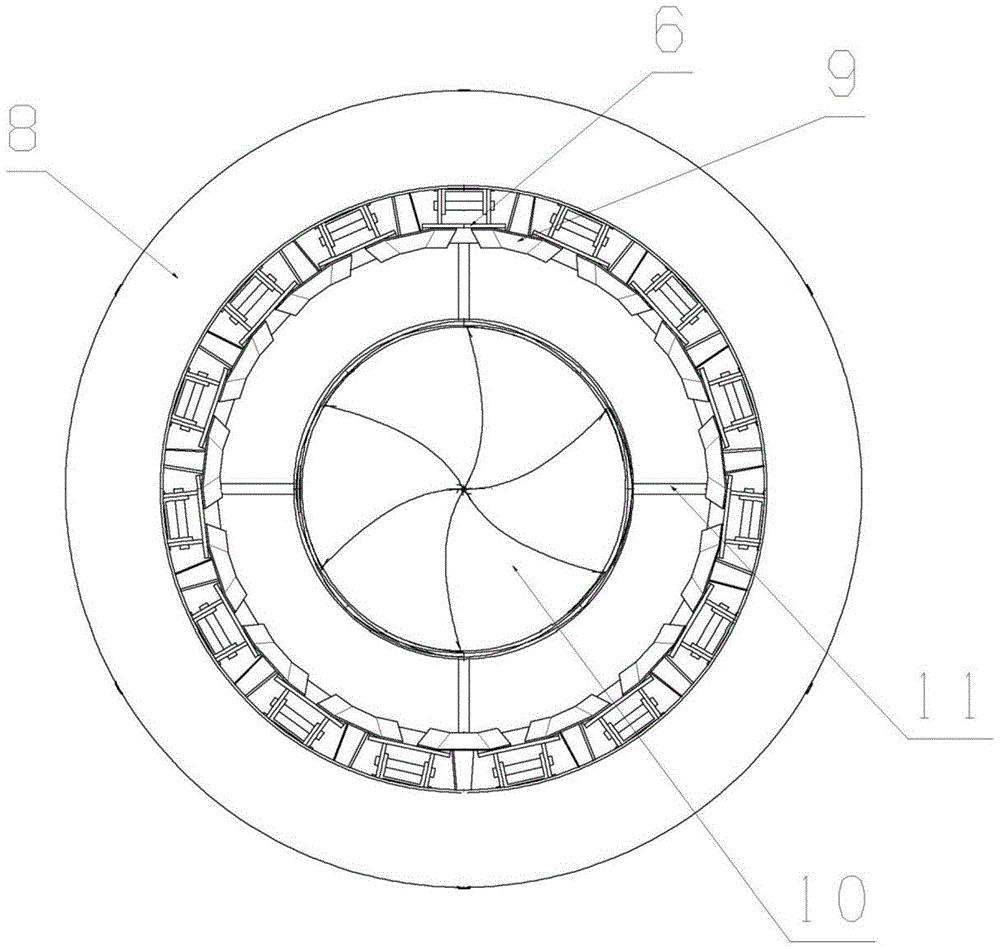

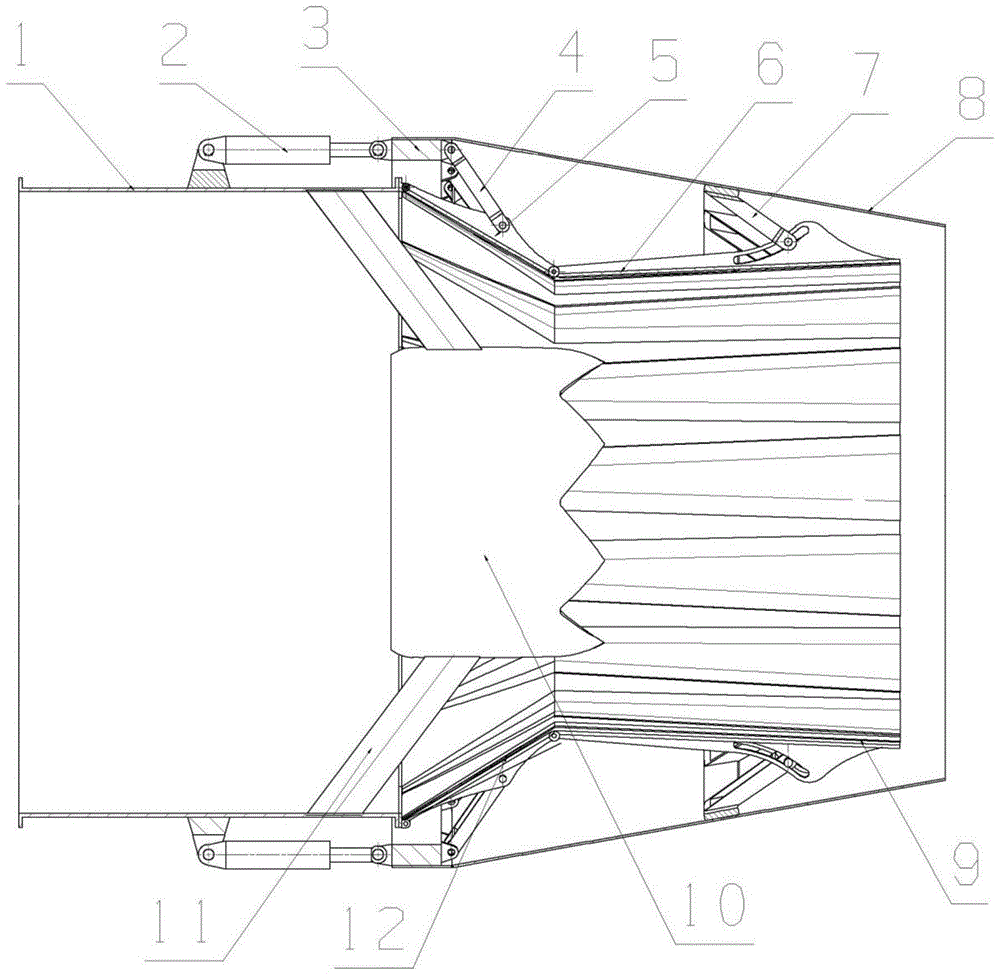

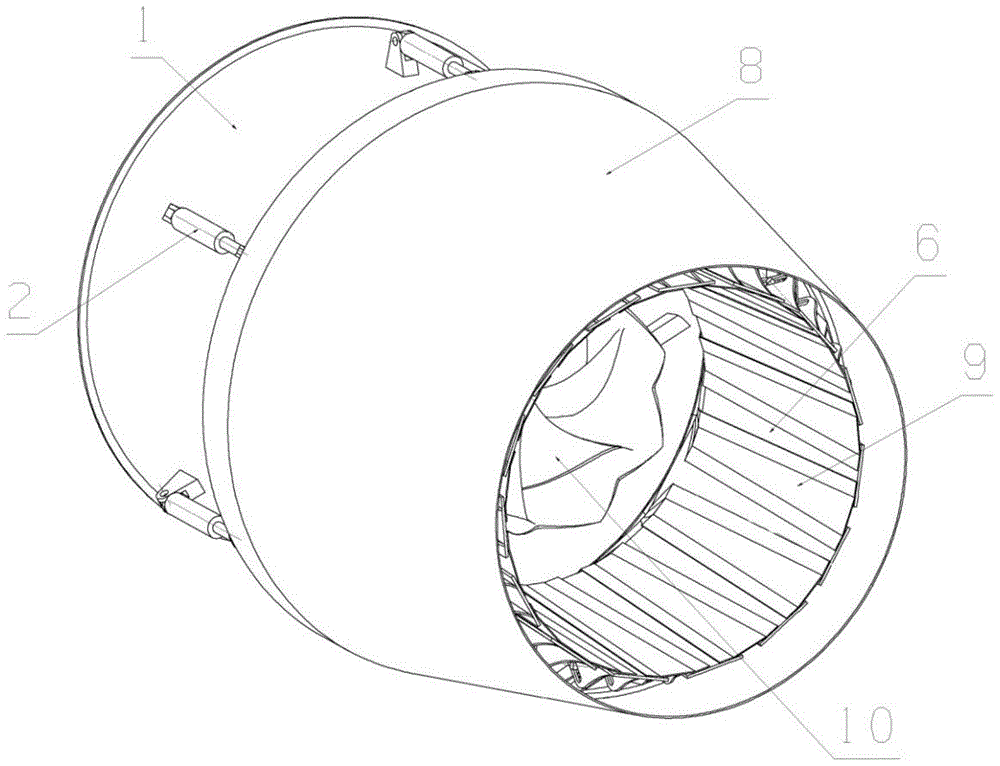

[0028] An axisymmetric shrinking and expanding nozzle of a single-action system is composed of a cylinder body 1 , a drive adjustment mechanism, a sealing member, a central blocking member and an outer cover 8 . Specifically:

[0029] The front end of the cylinder body 1 is connected with the engine as a supporting member for the entire nozzle.

[0030] The driving adjustment mechanism is composed of an actuator 2 , a pull rod 4 , a convergence adjustment plate 5 , an expansion adjustment plate 6 and a first bracket 7 . Among them, the actuator cylinder 2 is arranged along the circumferential direction of the nozzle, the front end is connected to the outer wall of the cylinder body 1 through a mechanical connection, and the rear end is connected to the tie rod 4 through a rotating pair; It is connected to the middle section of the outer side of the convergence adjustment plate 5; the front end of the convergence adjustment plate 5 is connected to the rear end of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com