Vacuum pump

A vacuum pump, fixed vane technology, used in pumps, pump components, axial flow pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0065] Hereinafter, the vacuum pump of the present invention will be described by taking a turbomolecular pump as one embodiment with reference to the drawings.

[0066] (The overall structure of the vacuum pump)

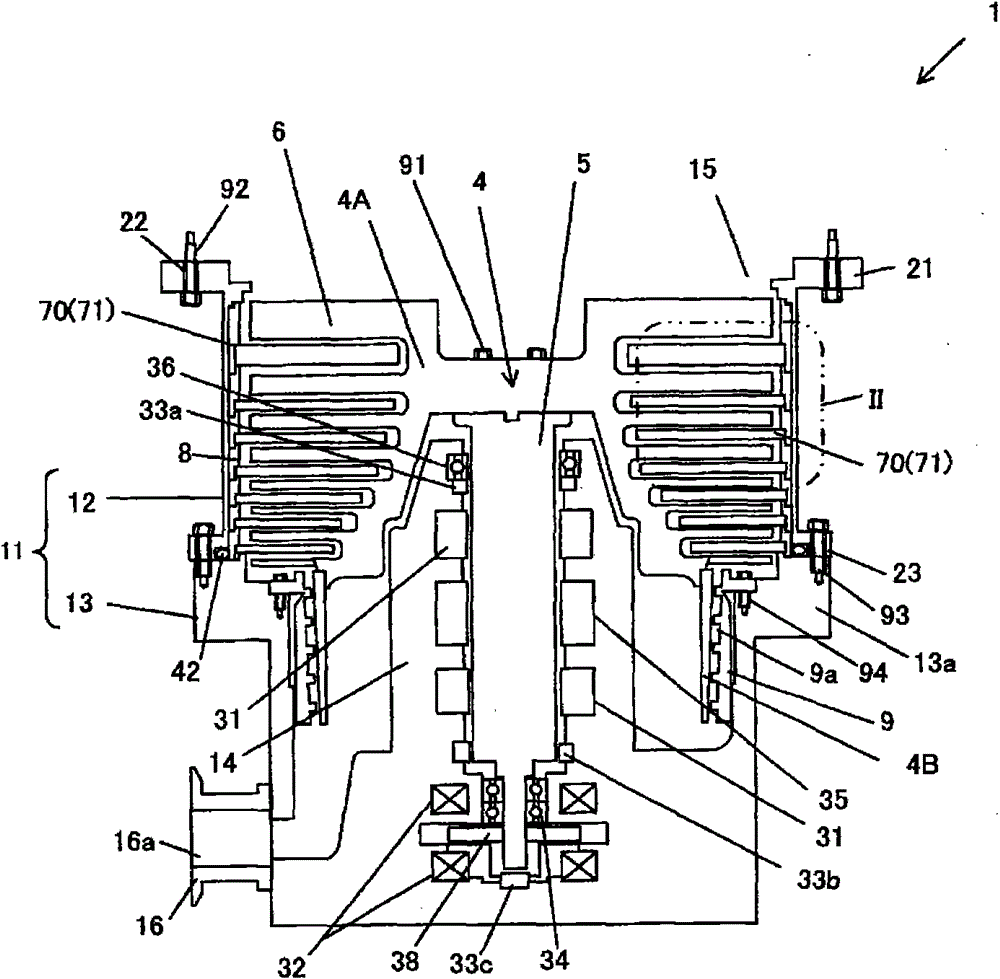

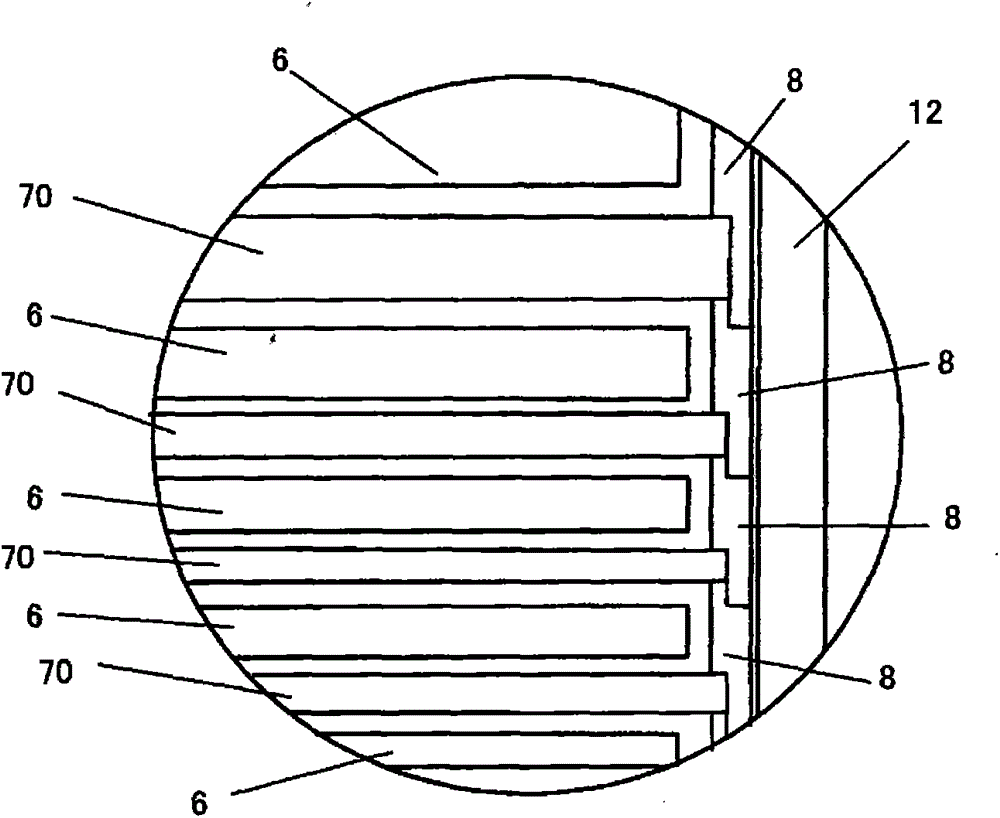

[0067] figure 1 is a cross-sectional view of the turbomolecular pump 1, figure 2 yes figure 1 Magnification of region II in .

[0068] The turbomolecular pump 1 includes a pump housing 11 formed of a casing member 12 and a base 13 fixed to the casing member 12 .

[0069] The casing member 12 has a substantially cylindrical shape, is formed of, for example, SUS, and has an upper flange 21 formed at an upper end thereof. A circular intake port 15 is formed inside the upper flange 21 of the case member 12 . Through-holes 22 for bolt insertion are formed in the upper flange 21 at approximately equal intervals in the circumferential direction. The turbomolecular pump 1 is an external device mounted on a semiconductor manufacturing device or the like after the bolt...

Embodiment approach 2

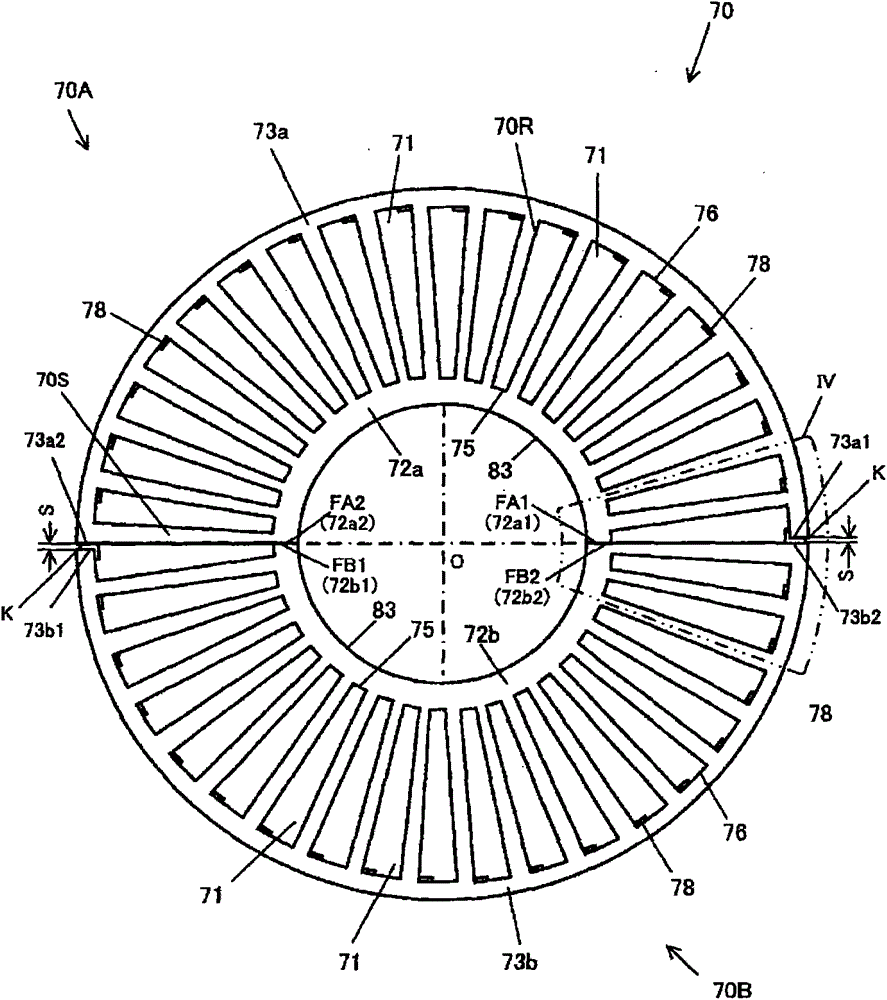

[0117] Figure 11 It is a sectional view of Embodiment 2 of the main part of the stationary blade part of this invention.

[0118] Embodiment 2 differs from Embodiment 1 in the following points.

[0119] (1) In the divided fixed blade portion 70A and the divided fixed blade portion 70B, the outer peripheral side support portion 76A connecting the stator blade 71 to the outer peripheral rim 73 a and the outer peripheral rim 73 b extends over the inner peripheral side support portion 75 similarly to the inner peripheral side support portion 75 . The entire length of the outer peripheral end portion 71So of the stator blade 71 is formed. That is, the opening portion 78 formed in Embodiment 1 for separating the front end side portion 77 from the outer peripheral side support portion 76 is not included.

[0120] (2) On the inner peripheral rim 72a and the inner peripheral rim 72b of the divided fixed blade portion 70A and the divided fixed blade portion 70B, there are respectivel...

Embodiment approach 3

[0128] Figure 12 It is a cross-sectional view of Embodiment 3 of the main part of the stationary blade part of the present invention.

[0129] Embodiment 3 differs from Embodiment 1 in the following points.

[0130] (1) In the divided fixed blade portion 70A and the divided fixed blade portion 70B, the outer peripheral side support portion connecting the outer peripheral side end portion 71So of the stator blade 71 to the outer peripheral rim 73 a and the inner peripheral side support portion of the stator blade 71 are not included. The end portion 71Si is an inner peripheral support portion connected to the inner peripheral rim 72a. That is, the outer peripheral end 71So and the inner peripheral end 71Si of each stator blade 71 are separated from the outer peripheral rim 73a, the inner peripheral rim 72a, or the inner peripheral rim 72b, and the outer peripheral rim 73b over the entire length, respectively.

[0131] (2) Among the divided fixed blade portion 70A and the div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com