Experiment table for detecting static rigidity of rolling linear guide rail pair

A technology of linear guide rail pair and static stiffness, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as errors, and achieve the effect of easy operation and simple and reliable loading method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

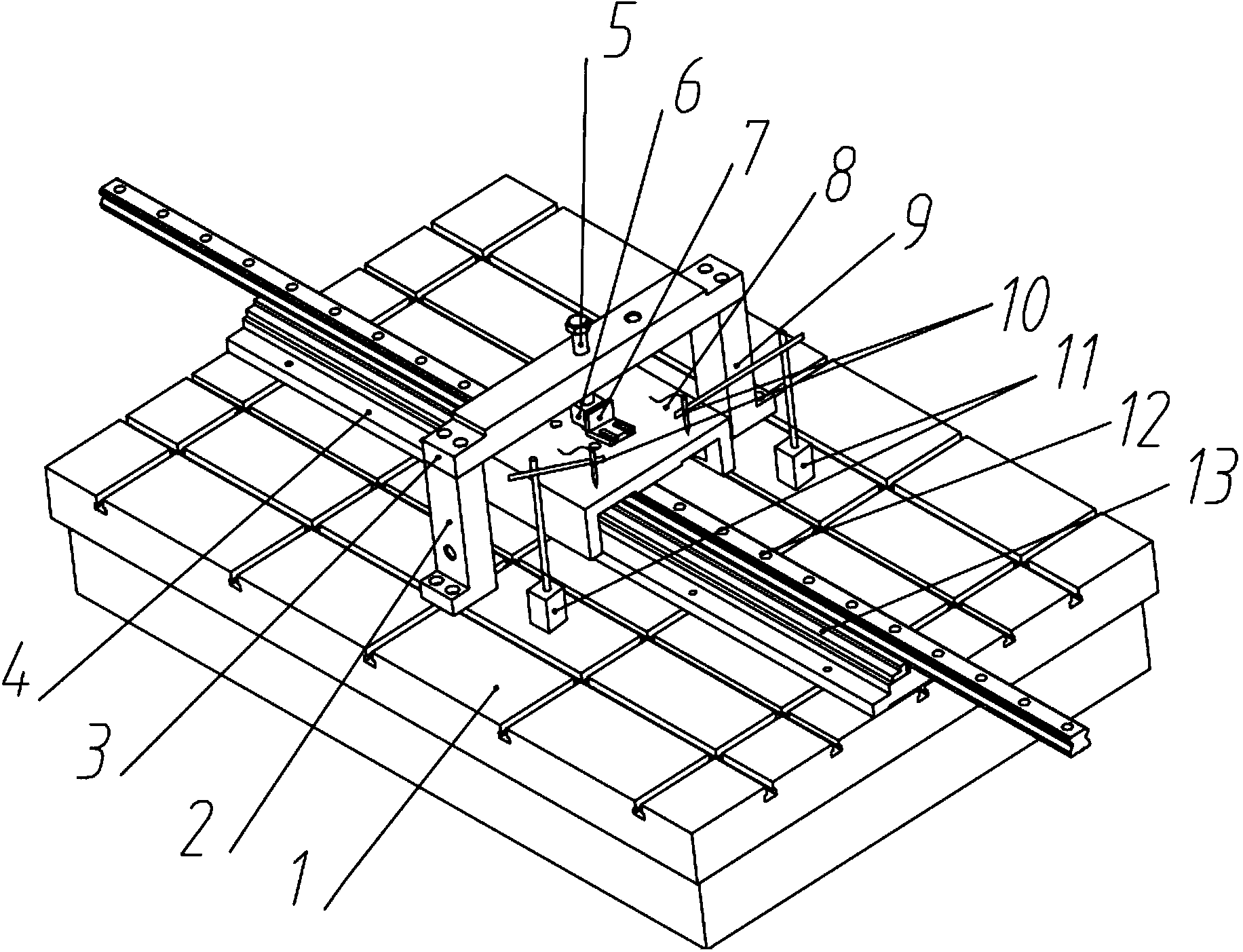

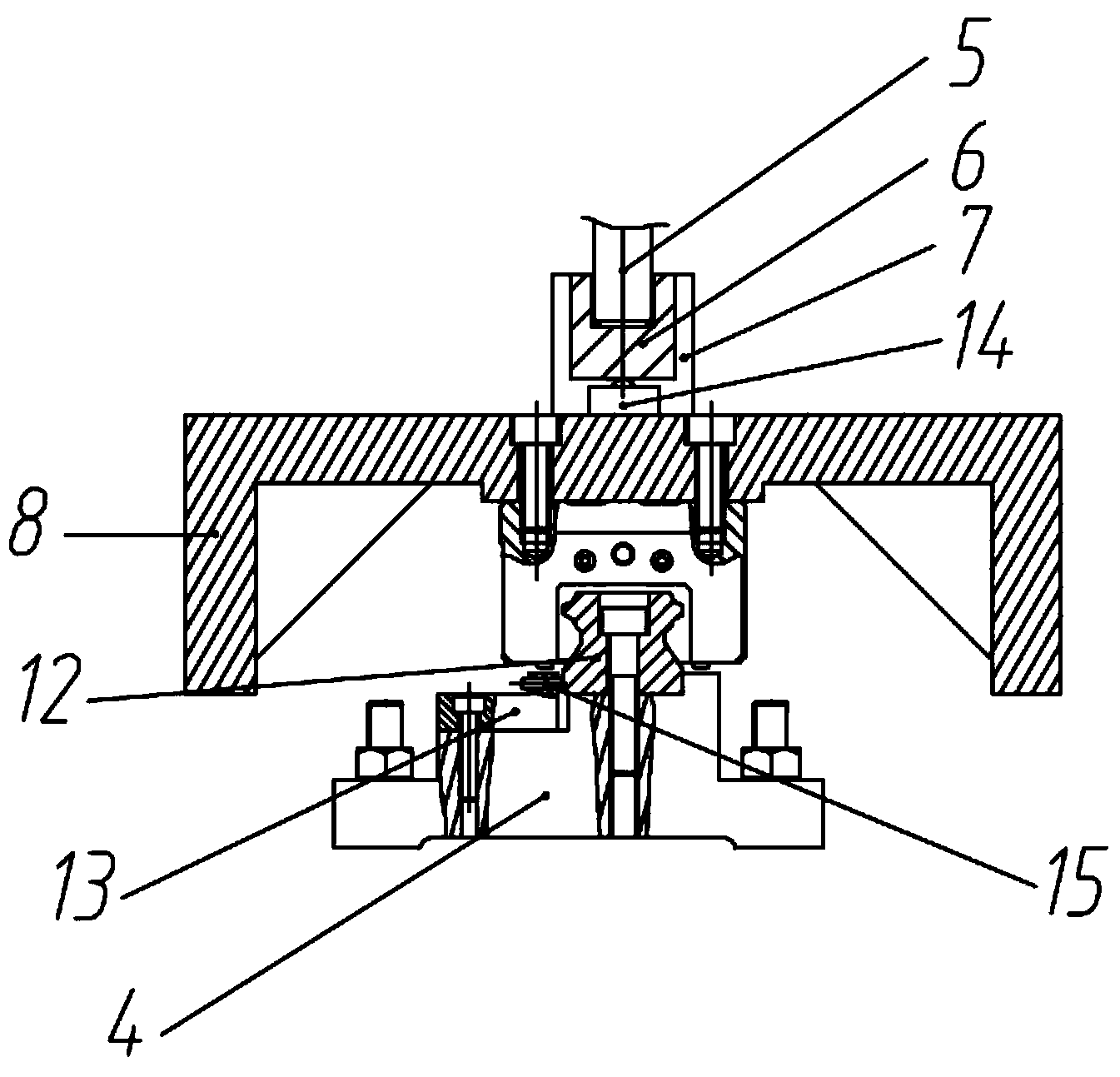

[0021] refer to figure 2 and image 3 , an experimental bench for testing the static stiffness of a rolling linear guide rail pair, including three parts: a guide rail pair positioning and clamping device, a loading device and a deformation detection device. The guide rail pair positioning and clamping device, the loading device and the deformation detection device are all fixed on the T-slot platform 1 .

[0022] Wherein the guide rail pair positioning and clamping device includes a guide rail pair mounting plate 4 , a fastening bar 13 , a test guide rail 12 and a pressing plate 8 . The guide rail auxiliary mounting plate 4 is longitudinally fixed on the upper surface width direction of the T-slot platform 1 along the T-slot platform ( image 3 In the middle of the front side), the test guide rail 12 and the fastening bar 13 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com