A device for integrating anti-counterfeiting and anti-tampering labels with random anti-counterfeiting fibers

A technology of anti-counterfeiting fibers and fibers, which is applied in the fields of commerce, instruments, and data processing applications, can solve problems such as unautomated continuous production processes, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

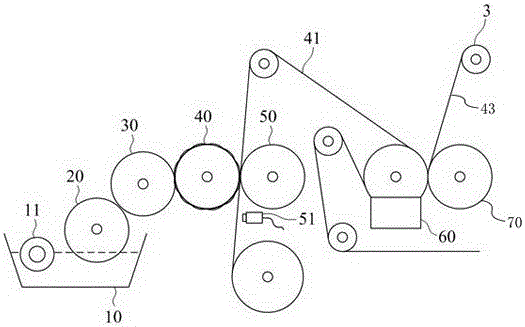

[0074] The integrated anti-counterfeiting and anti-channeling label of embodiment 1 of the present invention is attached to a random anti-counterfeiting fiber device, such as figure 2 The schematic diagram of the structure is shown.

[0075] In this embodiment 1, the integrated anti-counterfeiting and anti-channeling label of the present invention adheres to the device of random anti-counterfeiting fibers, including a gluing tank 10, a gluing roller 20, a gluing roller 30, a gluing roller 40, and a pressure roller 50. .

[0076] The gluing tank 10 is equipped with a stirring device 11 for fiber-containing glue, which fully mixes the fiber and the glue. The glue needs to have a certain viscosity to drive the fibers, and must also ensure a certain fluidity, so that the top roller 20 The fiber-containing glue can be fully transferred to the glue roller 30. The fiber and the glue must be fully stirred evenly to avoid the existence of agglomerated fibers. The fiber-containing glu...

Embodiment 2

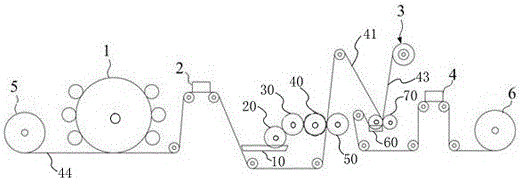

[0093] One of the embodiments of the integrated anti-counterfeiting and anti-channeling label of the present invention is attached to a random anti-counterfeiting fiber device, such as Figure 1 to Figure 5 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0094] The front end of the integrated anti-counterfeiting and anti-channeling label adhesion random anti-counterfeiting fiber device in Embodiment 1 of the present invention is connected with the unwinding device 5 of the load 41 and the continuous rolling printing device 1 of pictures and texts, and the inkjet device 2, and the rear end is connected There is the rewinding device 6 of the load, and the inkjet device 2 refers to printing the random anti-counterfeiting and anti-movement character da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com