Artificial travertine hole mold and cement-based non-burning artificial travertine preparation method

An artificial travertine and cement-based technology, applied in the field of building decoration materials, can solve the problems of difficult control of the shape of holes, high production cost of amphoteric metals, complicated preparation process, etc., and achieves adjustable hole size and hole distribution, rich styles, The effect of easy solid-liquid conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

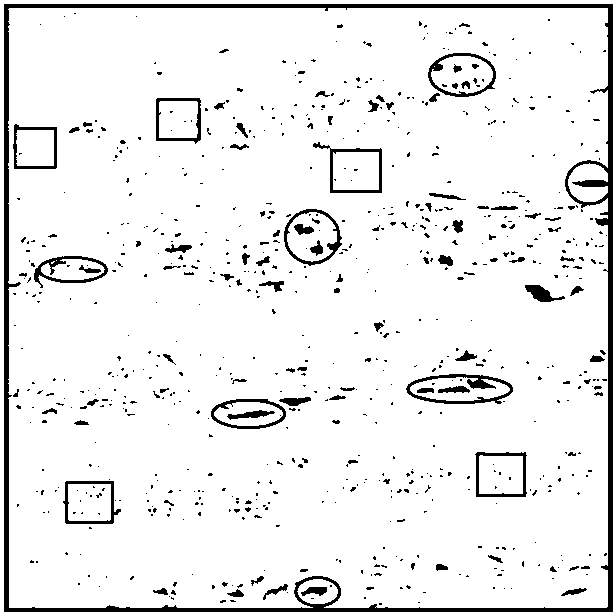

Image

Examples

preparation example Construction

[0037] The invention relates to a preparation method of cement-based unfired artificial travertine, comprising the following steps:

[0038] (1) Using a mold with a similar hole effect to natural travertine, phase change materials are used as injection molding materials, and solid phase change materials of different shapes are formed by injection molding equipment.

[0039] The phase change material includes one of ethylene-vinyl acetate copolymer, paraffin, polyethylene glycol, polyethylene, polyvinyl chloride and the like.

[0040] The vinyl acetate content of the ethylene-vinyl acetate copolymer is 30-45%.

[0041] Paraffin wax comprises one or more of No. 52 paraffin wax, No. 54 paraffin wax, No. 56 paraffin wax and No. 58 paraffin wax.

[0042] The molecular weight of polyethylene glycol is 1000-20000.

[0043] The molecular weight of polyethylene is 10,000-100,000.

[0044] The molecular weight of polyvinyl chloride is 50,000 to 100,000.

[0045] (2) according to the...

Embodiment 1

[0066] A preparation method of cement-based unfired artificial travertine, comprising the following steps:

[0067] (1) Select a mold with a similar hole effect to natural travertine, use ethylene-vinyl acetate copolymer with a vinyl acetate content of 40% as the injection molding material, and mold ethylene-vinyl acetate solids of different shapes through injection molding equipment;

[0068] (2) artificially arrange the ethylene-vinyl acetate copolymer solid described in step (1) on the bottom surface of a mold with a length of 32m, a width of 1.6m, and a height of 0.05m;

[0069] (3) Put 50 parts of 42.5R Portland cement and 30 parts of river sand into the mixing equipment and mix evenly, then put 5 parts of slaked lime, 1 part of polycarboxylate superplasticizer with a solid content of 50wt%, and 10 parts of water into Mix evenly in the mixing equipment, add the mixed material evenly into the mold described in step (2) for molding and curing, demould after the material is ...

Embodiment 2

[0073] A preparation method of cement-based unfired artificial travertine, comprising the following steps:

[0074] (1) Select a mold with a similar hole effect to natural travertine, use No. 52 paraffin as the injection molding material, and mold paraffin wax solids of different shapes through injection molding equipment;

[0075] (2) artificially arrange the paraffin wax solid described in step (1) on the bottom surface of a mold with a length of 1m, a width of 1m, and a height of 0.03m;

[0076] (3) Put 65 parts of 52.5R sulfoaluminate cement and 15 parts of quartz sand into the mixing equipment and mix evenly, then mix 2 parts of slaked lime, 3 parts of steel slag, 2 parts of naphthalene-based water reducer with a solid content of 30wt%, 20 parts Put the water into the mixing equipment and mix evenly, add the mixed material evenly into the mold described in step (2) to form and maintain, and remove the mold after the material is completely solidified, and perform fine poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com