Noise-proof pelletizer

A granulator and anti-noise technology, applied in the field of mechanical equipment, can solve problems such as interference with the life and work of staff, impact on physical and mental health, and high noise, and achieve the effects of protecting physical and mental health, good sound insulation, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

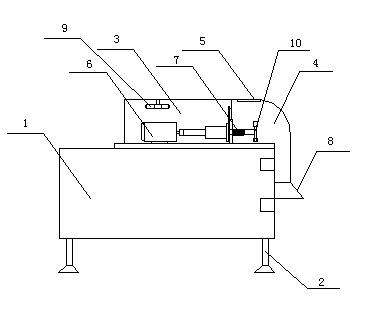

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes a support 1, a base 2, a horizontal noise-proof cover 3, a vertical noise-proof cover 4, an observation window 5, a motor 6, an elastic cutter seat 7, a discharge port 8, a fan 9 and cutter disc 10, the top of base 2 is provided with support 1, and the top of support 1 is provided with motor 6, and motor 6 is connected with cutter disc 10 by elastic cutter seat 7, and on motor 6 and elastic cutter seat 7 The cover is connected with a horizontal noise-proof cover 3 and a vertical noise-proof cover 4, the lower end of the vertical noise-proof cover 4 is connected with a discharge port 8, a fan 9 is arranged on the inner side of the horizontal noise-proof cover 3, and the vertical noise-proof cover 4 An observation window 5 is provided on the outside of the cover.

[0009] The horizontal anti-noise cover 3 and the vertical anti-noise cover 4 are made of composite steel plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com