Test method for penetration effect of emulsified asphalt in permeable layer

A technology for emulsified asphalt and effect testing, which is applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of lack of qualitative and quantitative index requirements, special technical indicators and test methods for penetrating emulsified asphalt penetration, and achieve Credible test results, reliable penetration speed, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Introduce the embodiment of the present invention in detail below, and its test method is as follows:

[0027] 1. Preparation of instruments and materials

[0028] ⑴ Penetration effect tester of emulsified asphalt

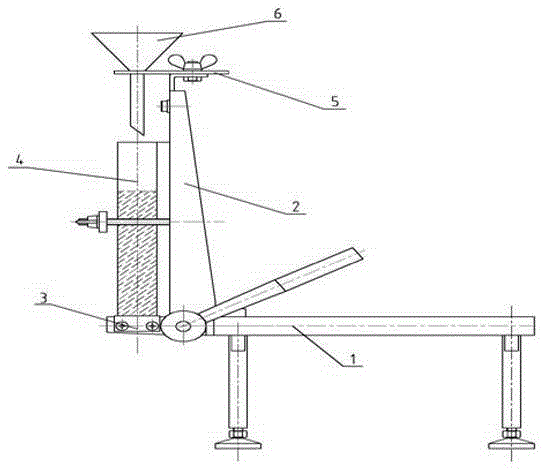

[0029] Such as figure 1 As shown, the penetrating effect tester of emulsified asphalt is composed of machine base 1, vertical plate 2, movable support plate 3, 50ml bottomless glass measuring cylinder 4, funnel bracket 5 and funnel 6;

[0030] On the upper end of the machine base 1, the vertical plate 2 is fixed with screws and washers, and the vertical surface of the vertical plate 2 is flush with the end of the machine base 1 and constitutes vertical. The 50ml bottomless glass measuring cylinder 4 is installed on the side of the vertical plate 2. The measuring cylinder 4 is fixed in the groove of the measuring cylinder guide seat by the plastic pressure plate and the disc nut through the stud bolts. The bottom of the measuring cylinder 4 should be close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com