Plug type binding post

A connection terminal and plug-in technology, which is applied in the direction of connecting end caps, connections, contact parts, etc., can solve the problems of reducing wiring efficiency, reducing labor intensity, increasing wiring procedures, etc., and achieves high construction efficiency and simple wiring work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

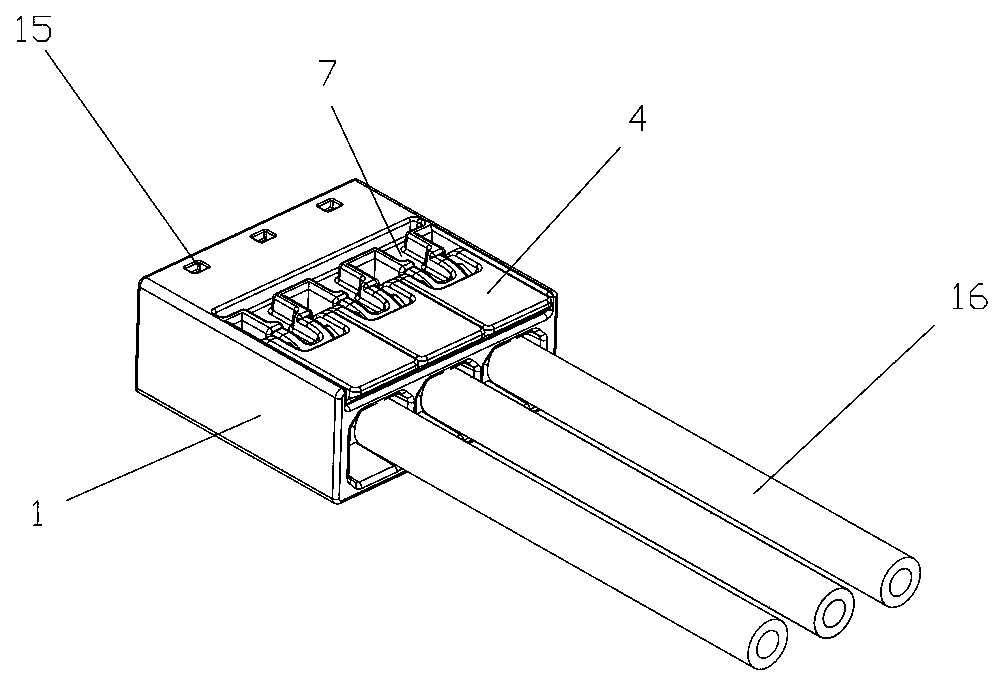

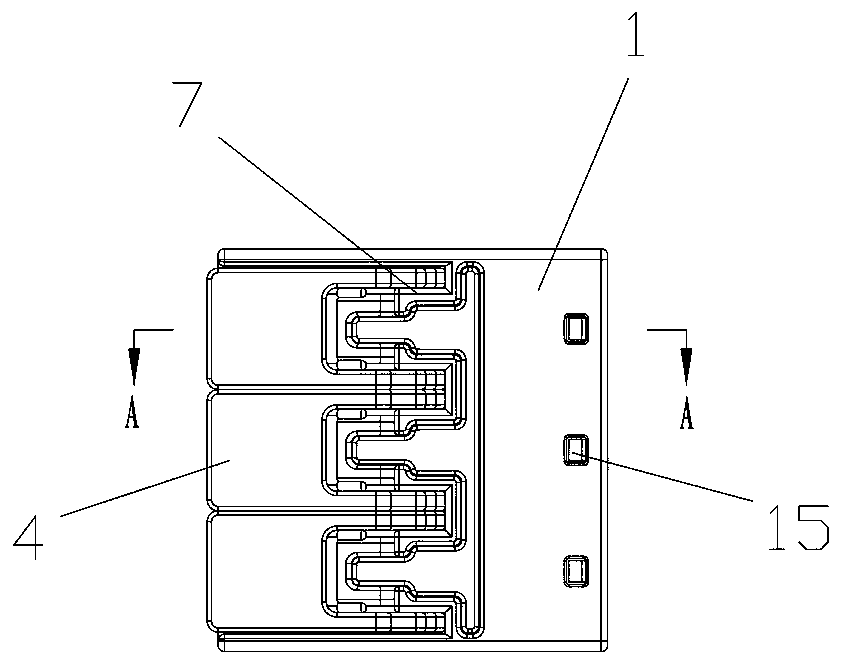

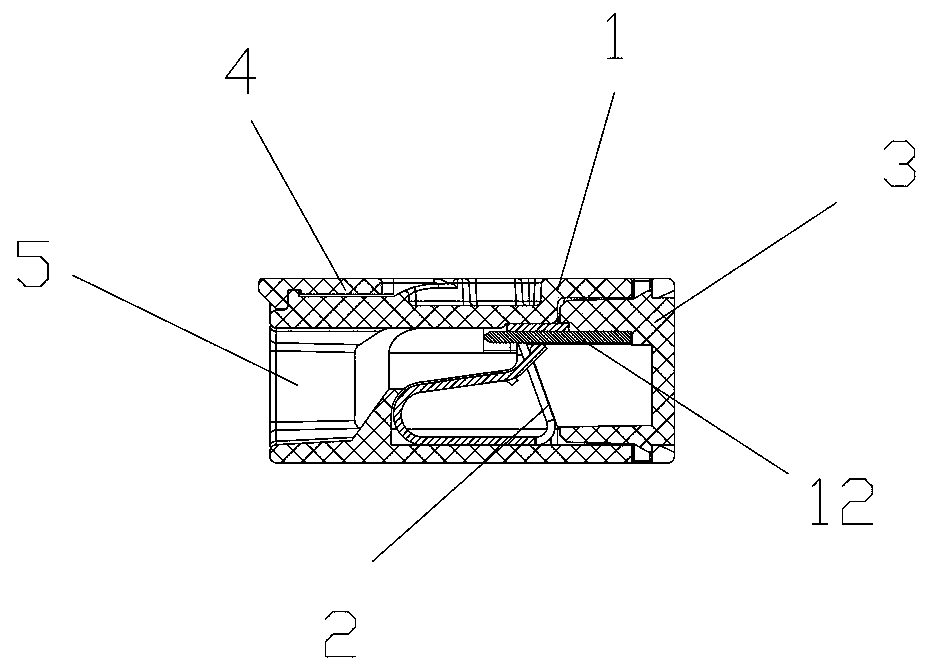

[0035] A plug-in terminal described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8As shown, it includes an insulating housing 1 with an integrated structure and a cavity to form a hollow structure, a conductive metal connector 2 arranged in the cavity of the insulating housing, and a rear cover arranged on the back of the insulating housing. 3 and the flip handle 4 provided on the top surface of the insulating housing and corresponding to the conductive metal connector; one end of the insulating housing is provided with a corresponding conductive metal connector and allows the wire 16 to be inserted into the wire insertion port to form a connection with the conductive metal connector 5. The other end of the insulating housing is provided with a housing opening 6 that allows conductive metal connectors to be put into the insulating housing and fitted with the back cover. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com