Ground terminal pliers and grounding method

A grounding method and technology for grounding terminals, which are applied to equipment connecting/terminating cables, etc., can solve the problems of potential safety hazards of power system maintenance equipment, electric induction accidents of maintenance workers, and weak contact of grounding piles, so as to avoid personal electric shock. Accidents, the effect of improving installation efficiency and grounding reliability, and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

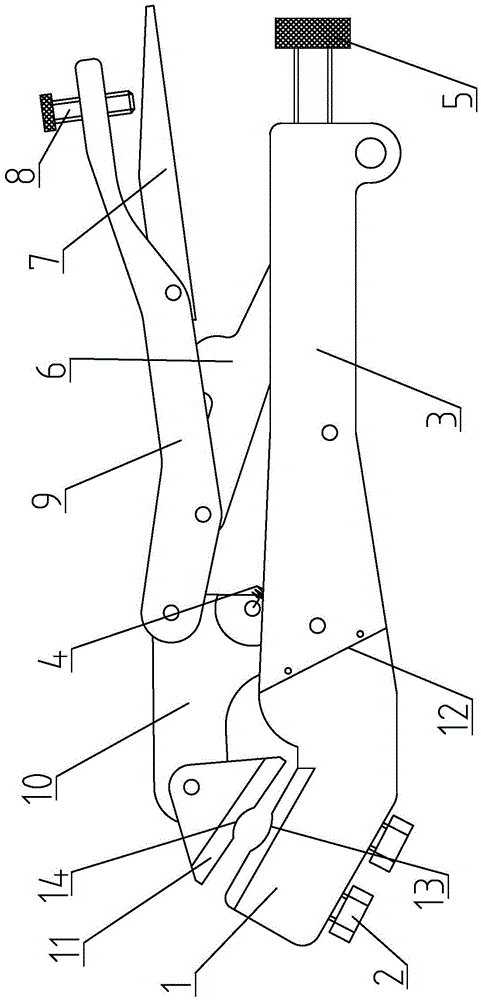

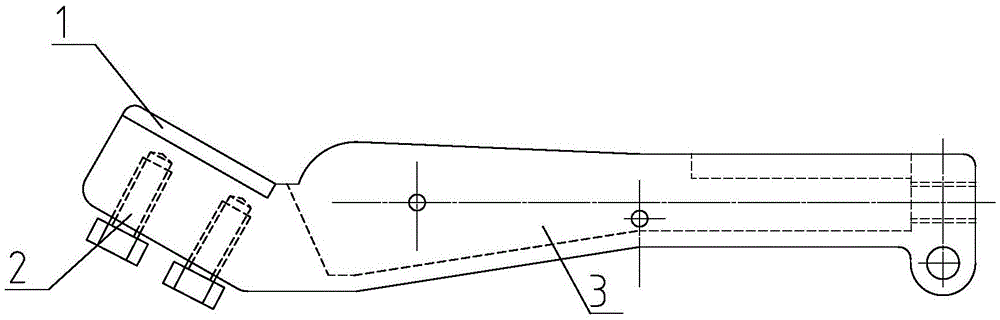

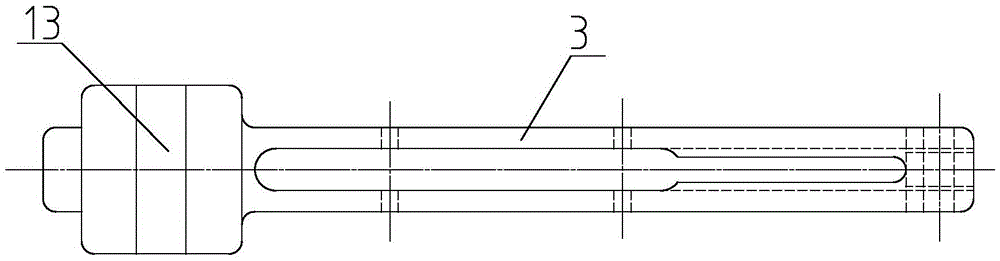

[0023] See Figure 1-Figure 3 , a grounding end pliers, comprising a movable jaw 11, a static jaw 1, a triangular fulcrum connecting plate 10, a ground wire connecting terminal 2, a combined force lever 9, a main pliers body lever 3, a fulcrum spring 4, and a section adjustment link 6. Fixed top wire 8, cross-section top screw rod 5, pull-back grip rod 7, movable jaw 11 is hinged with triangular fulcrum connecting plate 10, static jaw 1 is provided with ground wire connection terminal 2, static jaw 1 is connected with main tongs The body grip rod 3 is connected, and the end surface of the static jaw 1 is provided with a static jaw oval groove 13; the triangular fulcrum connecting plate 10 is hinged with one end of the combined force grip rod 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com