Drop assistance apparatus, filler system, and filling assistance method

An auxiliary device and assembly technology, which is applied in packaging, packaging food, packaging eggs, etc., can solve the problems of filling device failure, hindering the movement of clamping components, and complicated installation of filling devices, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

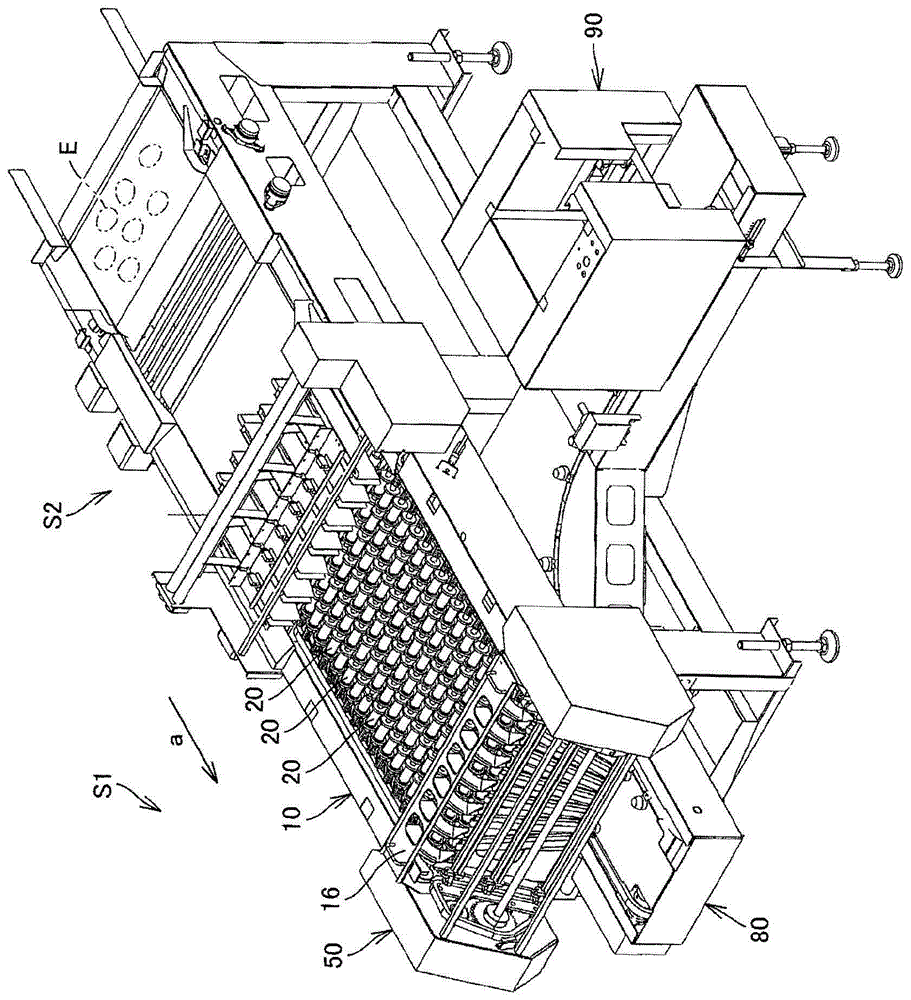

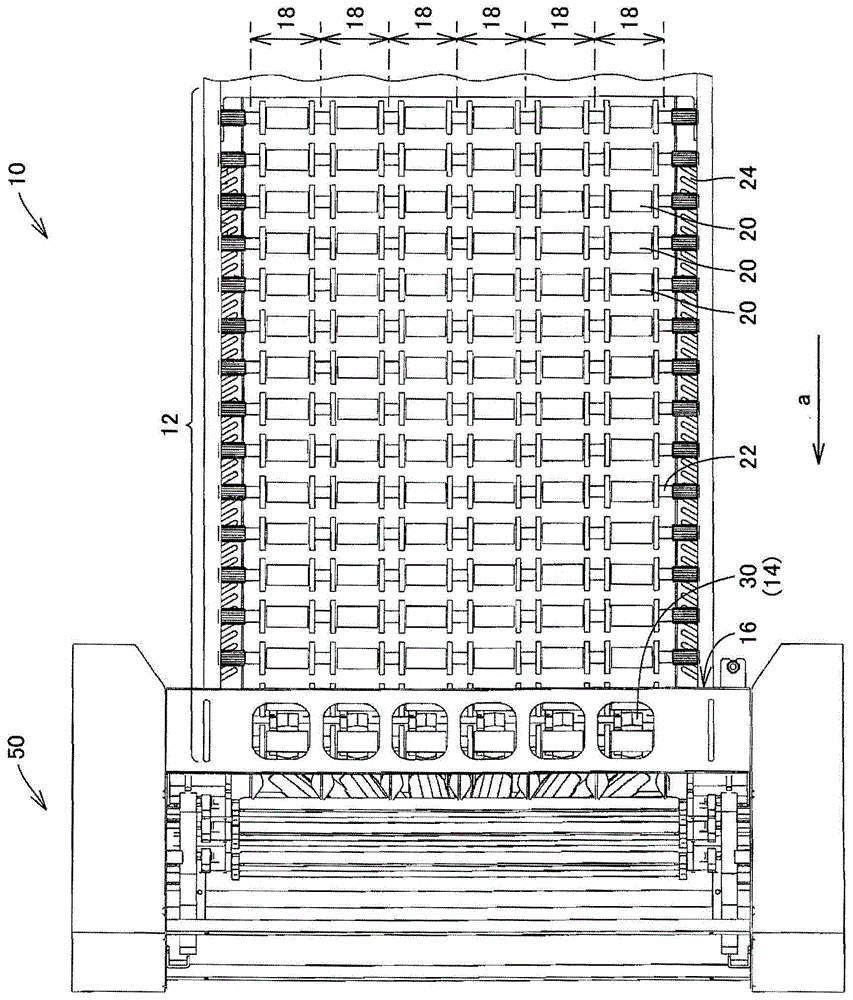

[0039] A filling system according to an embodiment of the present invention will be described. In the following description, the filling system which fills a large quantity of eggs E into a storage container is demonstrated using drawing using preferable embodiment.

[0040] [Filling system]

[0041] Such as figure 1 As shown, the filling system S1 according to the embodiment of the present invention is a storage container T ( figure 2 ) of the so-called agricultural packaging machine. As a conventional agricultural packaging machine, for example, there is a filling system described in JP-A-5-8851.

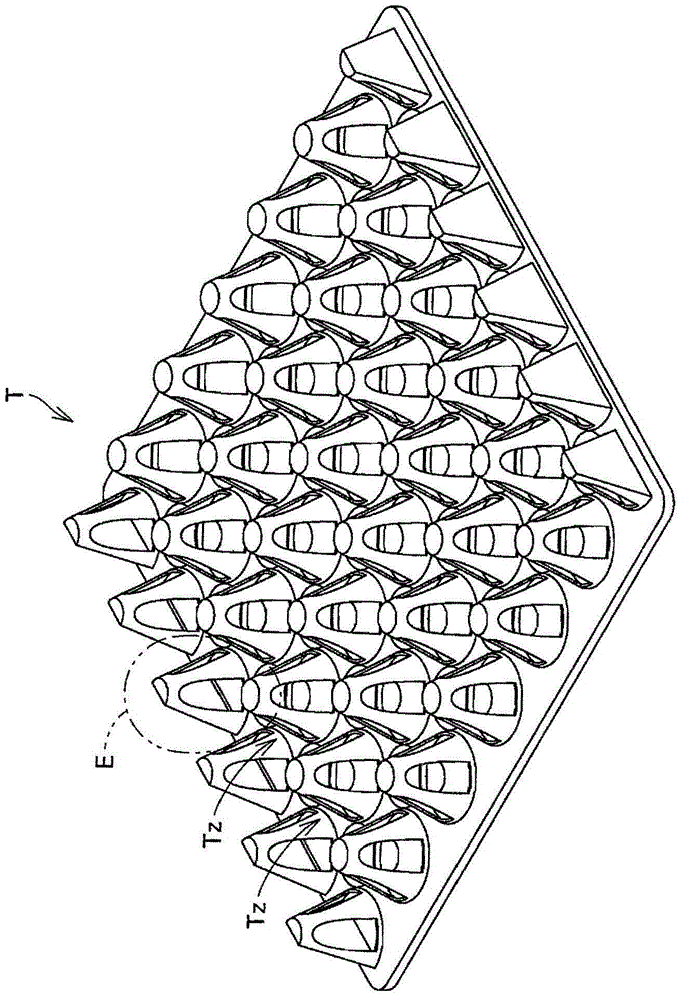

[0042] Such as figure 2 As shown, the storage container T is formed in a rectangular shape in plan view, and is formed with a plurality of protruding portions. In the storage container T, one storage seat Tz is formed by four protruding portions having a quadrangular shape. The storage seats are formed in a grid of n columns×m rows (n and m are ordinal numbers), and one egg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com