Pilot test production line and production process of emulsion explosives

An emulsion explosive, production line technology, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of insufficient attention to process technology and equipment development and application, simple test equipment, unmatched functions, etc., to achieve good market prospects and promotion. The effect of application value, simple and effective connection relationship, and ingenious design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

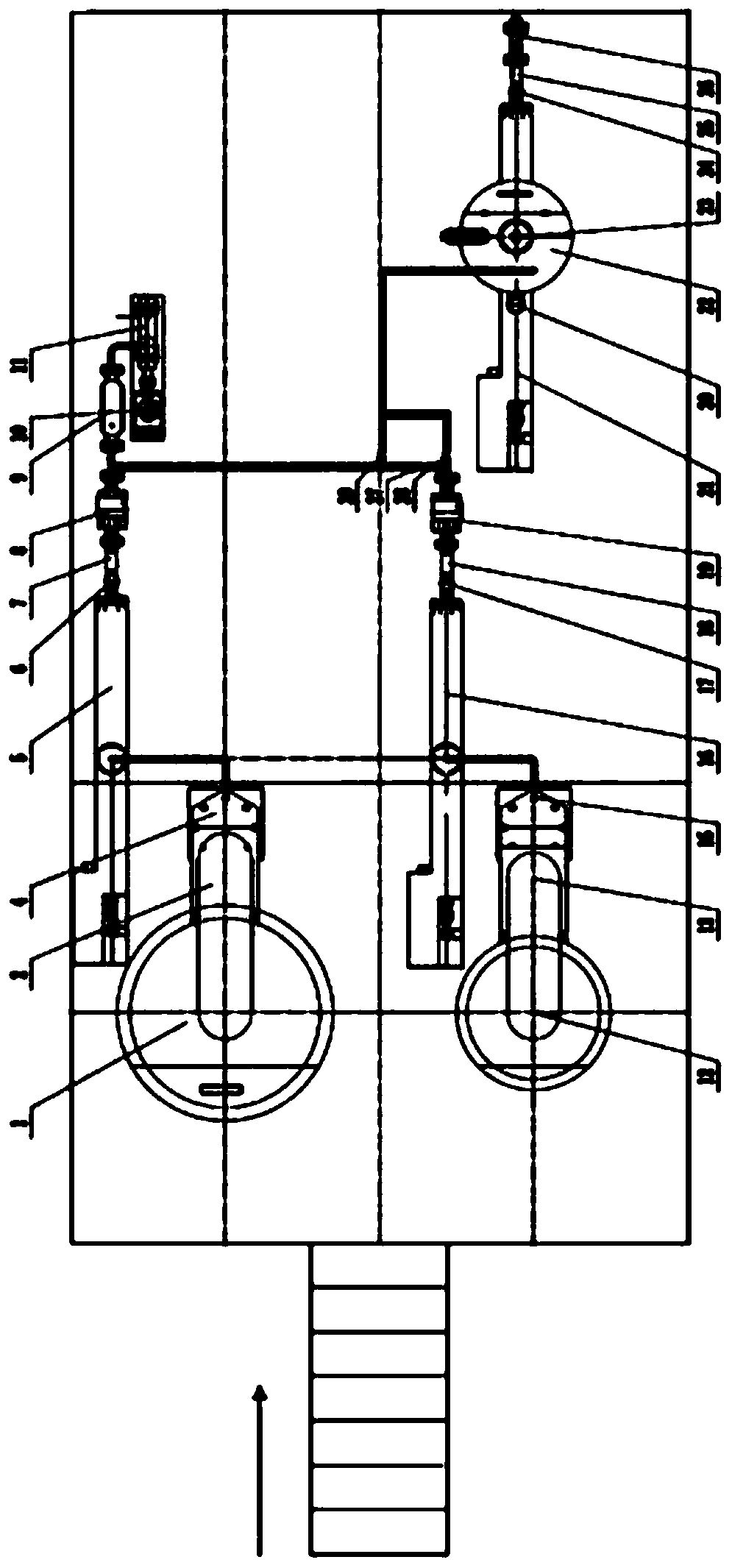

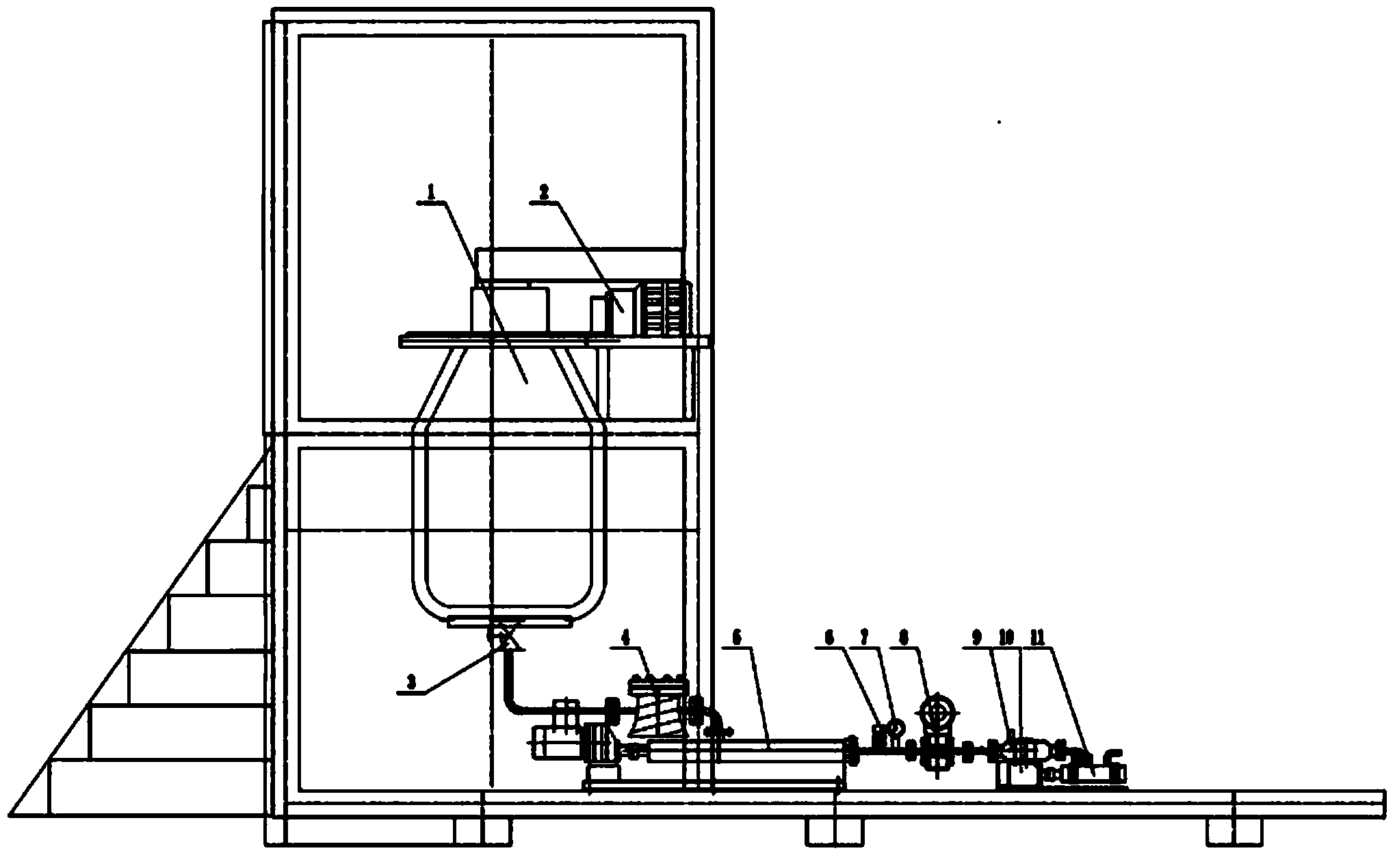

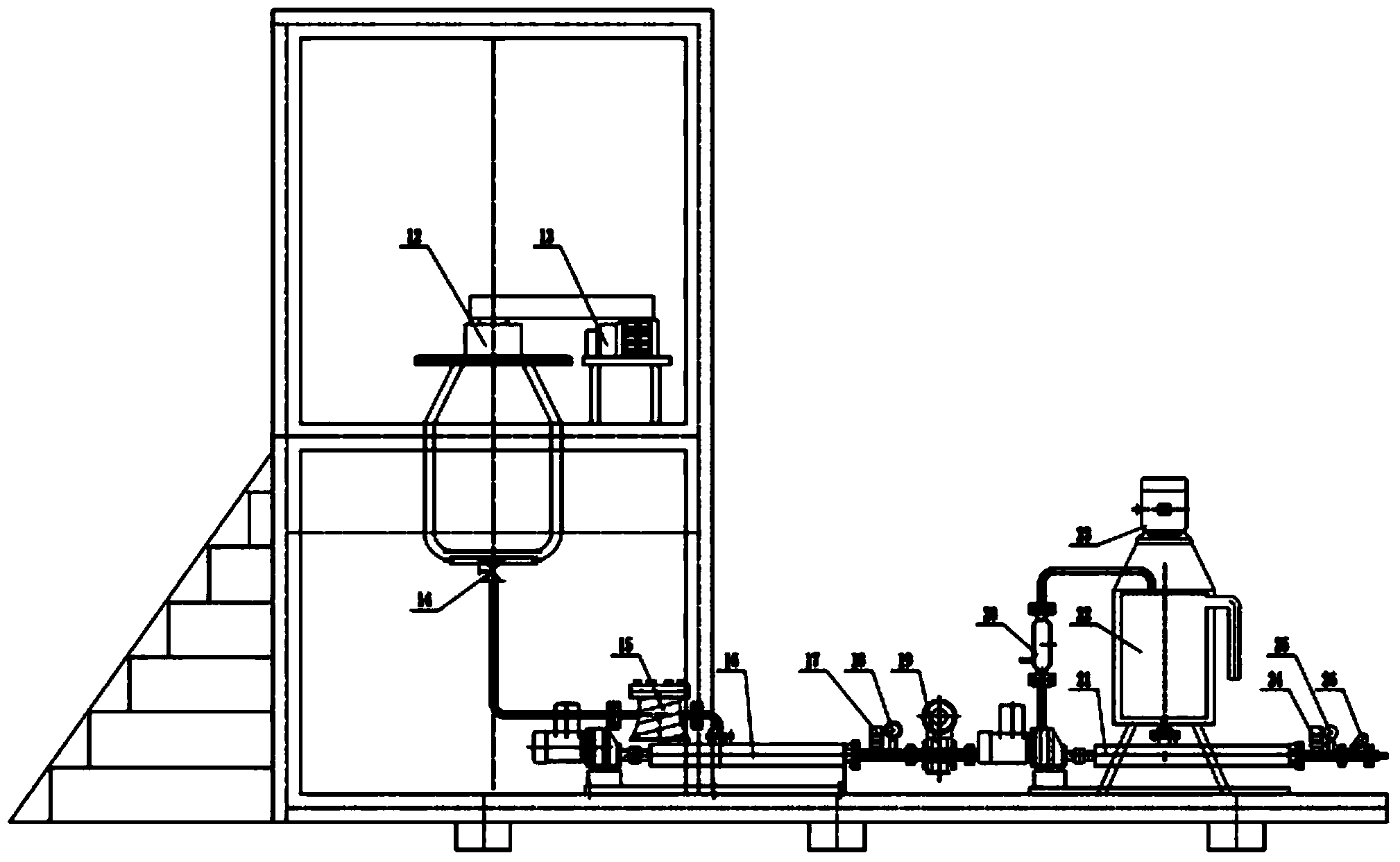

[0039] A pilot production line for emulsion explosives, including a water phase system, an oil phase system, a closed emulsification system and an open emulsification system, wherein the water phase system includes a water phase tank 1, a water phase feeding valve 3, Water phase filter 4, water phase screw pump 5; Described oil phase system comprises successively connected oil phase tank 12, oil phase feeding valve 14, oil phase filter 15, oil phase screw pump 16; Described closed emulsification The system includes a closed emulsifier motor 10, a closed emulsifier 11 and a first static mixer 9 connected in sequence; the open emulsification system includes an open emulsifier motor 23, an open emulsifier 22 and a second static mixer connected in sequence device 20, the outlet end of the open emulsifier 22 is connected to the matrix pump 21, safety valve 24, pressure gauge 25 and angle seat valve 26 in sequence; The mixer 9 is connected, the oil phase screw pump 16 is connected w...

Embodiment 2

[0044] A pilot production line for emulsion explosives, the structure of which is as described in Example 1. The difference is that the pilot production line for emulsion explosives is set on a mobile platform, which is convenient for moving and transporting the entire pilot production line for emulsion explosives. The explosives pilot test production line was moved to another place for pilot test.

Embodiment 3

[0046] A pilot production line for emulsion explosives, the structure of which is as described in Example 1, the difference is that the open emulsifier is a special emulsifier for emulsion explosives described in the patent publication number CN103193559A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com