Automatic feather collecting device for mechanical arm of washing and dehydrating machine

A technology of manipulators and washing machines, which is applied in the direction of washing/scouring of animal loose hair fibers, can solve the problems of uneven feather collection tubes, slow collection speed, and blockage of the collection tubes, so as to ensure the safety of personnel, reduce labor intensity, Uniform hair collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

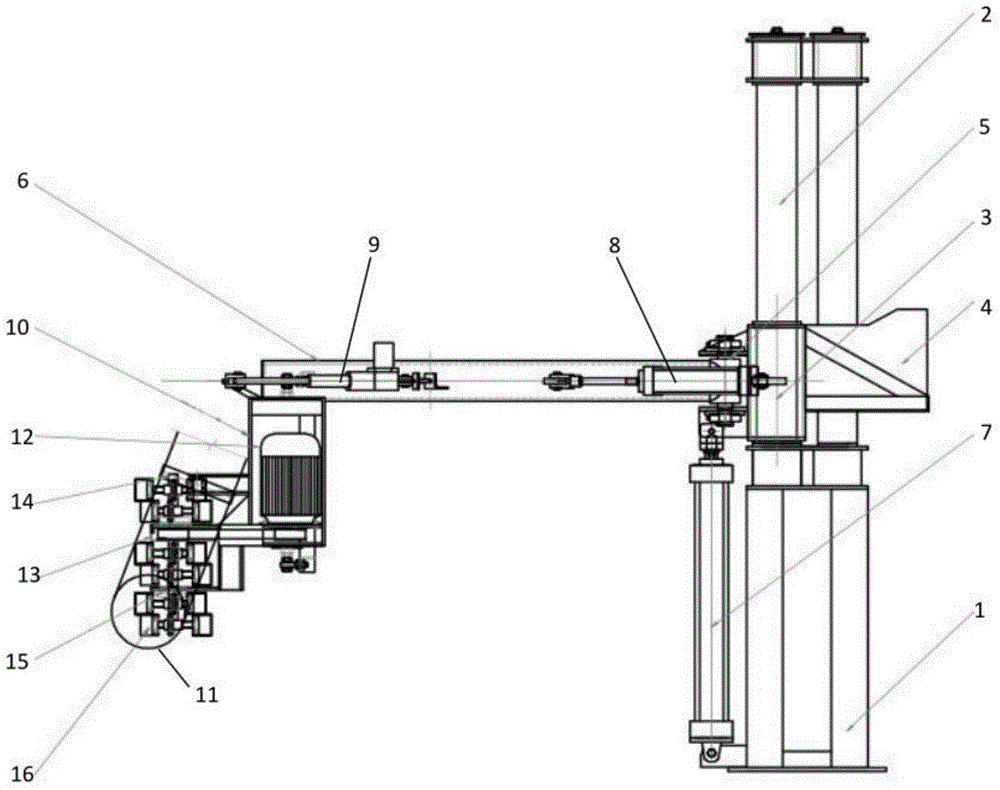

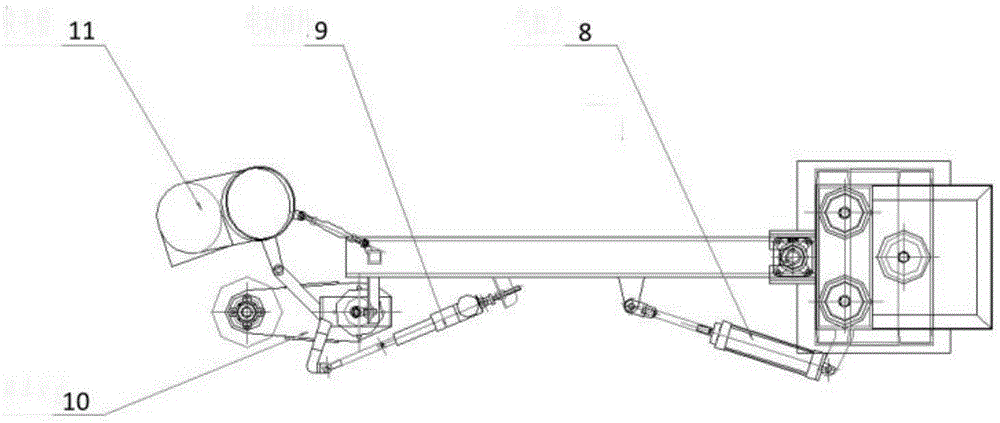

[0018] Such as figure 1 , 2 As shown, an automatic hair collection device for a manipulator of a washing machine includes a leg 1, a sliding guide column 2, a sliding sleeve 3, a counterweight box 4, a swing arm shaft 5, a swing arm 6, a first cylinder 7, a second Cylinder 8, electric pushrod 9, machine head 10 and hair collection tube 11. The support leg 1 is placed vertically, and the sliding guide column 2 is fixedly installed on the top. The sliding sleeve 3 is sleeved on the sliding guide column 2, the counterweight box 4 is installed on one side, and the swing arm 6 is rotatably connected to the swing arm shaft 5 on the other side.

[0019] The first cylinder 7 is vertically fixedly installed with the swing arm 6, and the front end is connected to the bottom side of the swing arm 6, and the rear end is connected to the lower part of the leg 1 to control the sw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap