Apparatus for manufacturing molded articles, method for manufacturing molded article and molded article

A production device and production method technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low cost, complex structure of resin packaging devices, and reduced resin use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

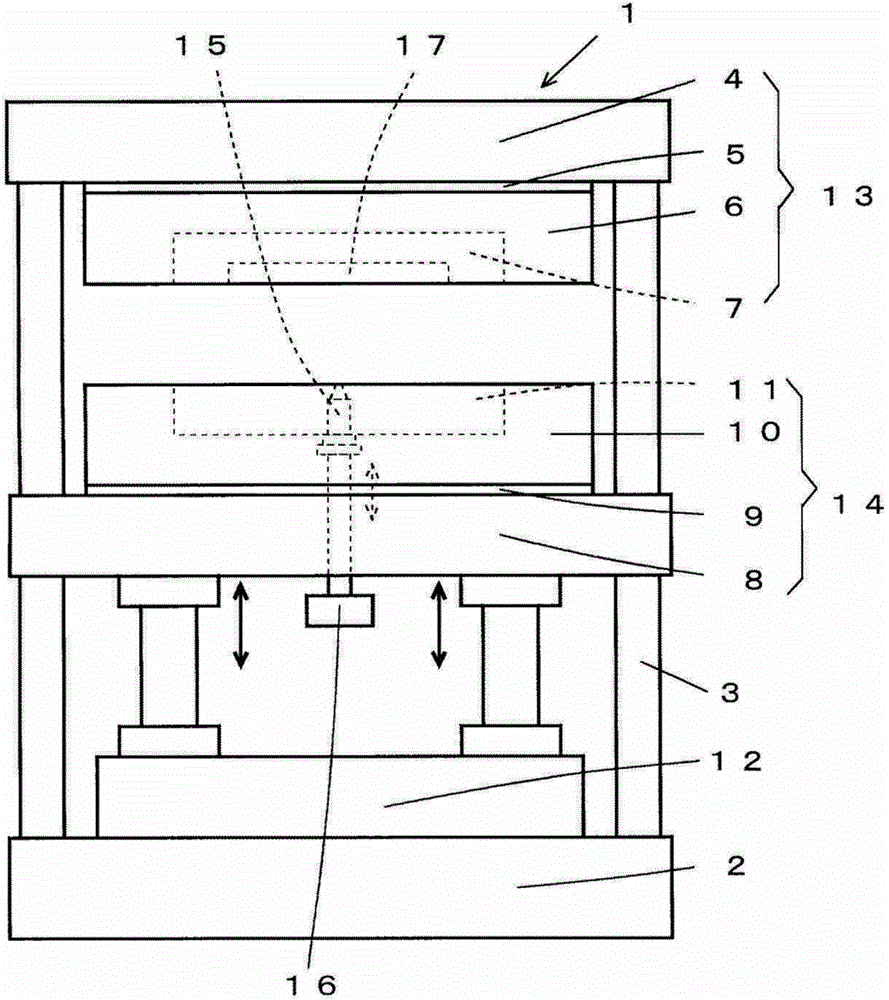

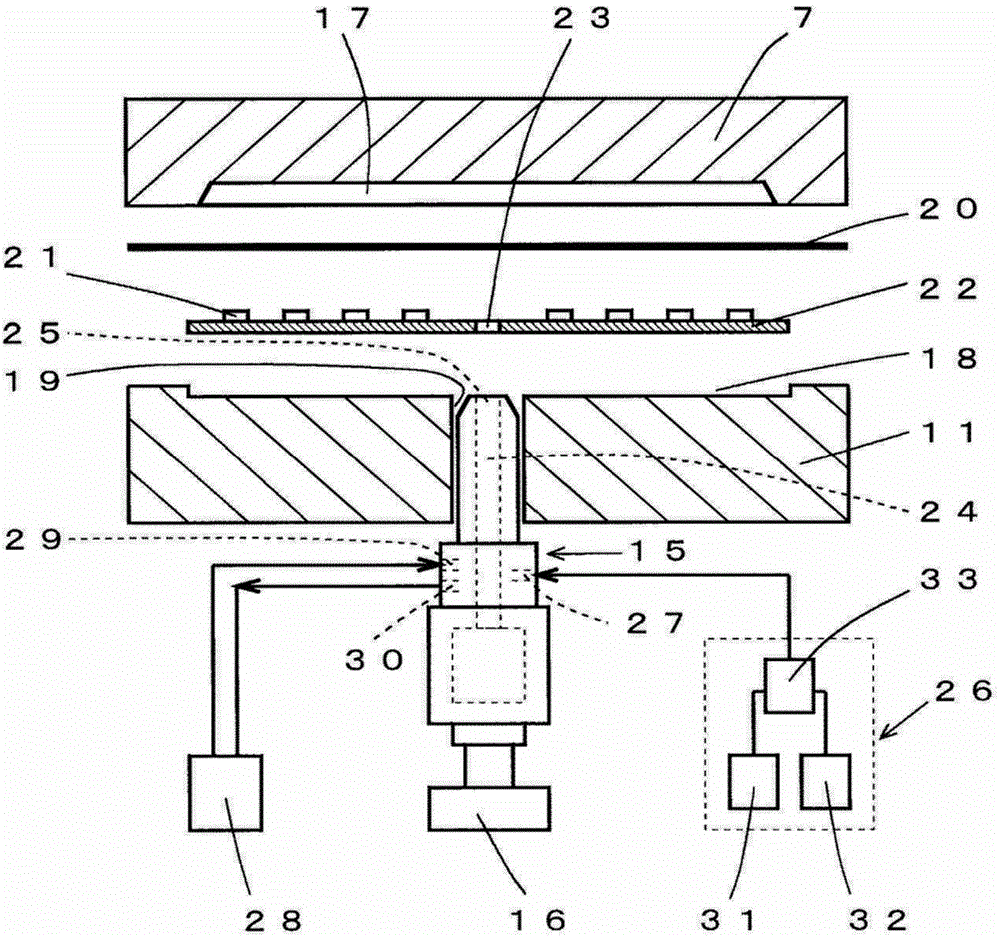

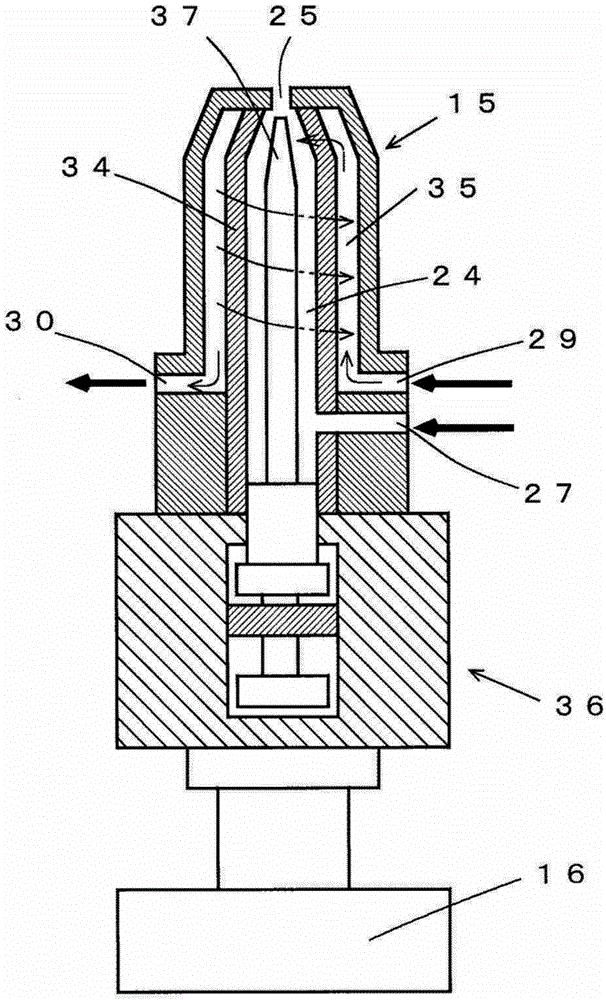

[0110] The molded product production apparatus of the present invention has the following configuration. That is, the through passage is provided in the molding die facing the cavity. The injection member can move forward and backward freely in the through channel. A liquid resin made of a thermosetting resin is supplied to a resin flow channel provided inside the injection member. The liquid resin is injected into the cavity from the injection port provided at the front end of the injection member through the opening provided in the support. The resin is molded and hardened by heating the injected liquid resin. The injection member is retracted from the cured resin to automatically separate the cured resin from the front end of the injection member.

[0111] Below, refer to Figure 1 to Figure 11 , an example of the molded product production apparatus according to the present invention will be described. Any drawing in the present application is appropriately omitted or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com