Intensity checking method used for disc brake bracket

A disc brake and strength checking technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of inaccurate strength checking, non-convergence of contact calculation, and failure to consider bolt cantilever effect bending moment, etc. , to reduce the probability of safety accidents, reduce the risk of maintenance and replacement, and eliminate subjectivity and randomness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

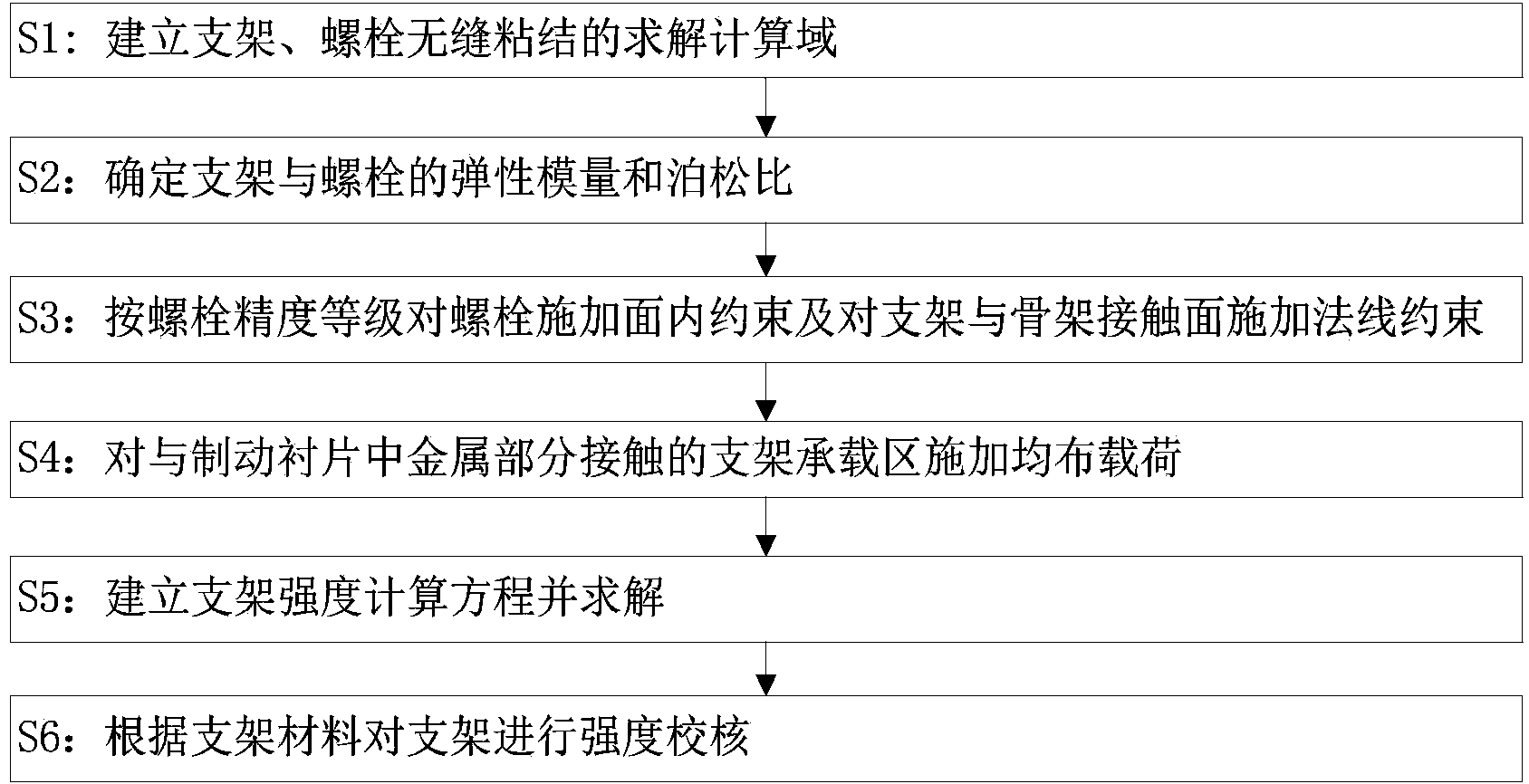

[0026] The following takes the 24.5-inch air disc brake bracket as an example, according to the attached figure 1 The flow chart of the strength checking method shown further elaborates the present invention in detail.

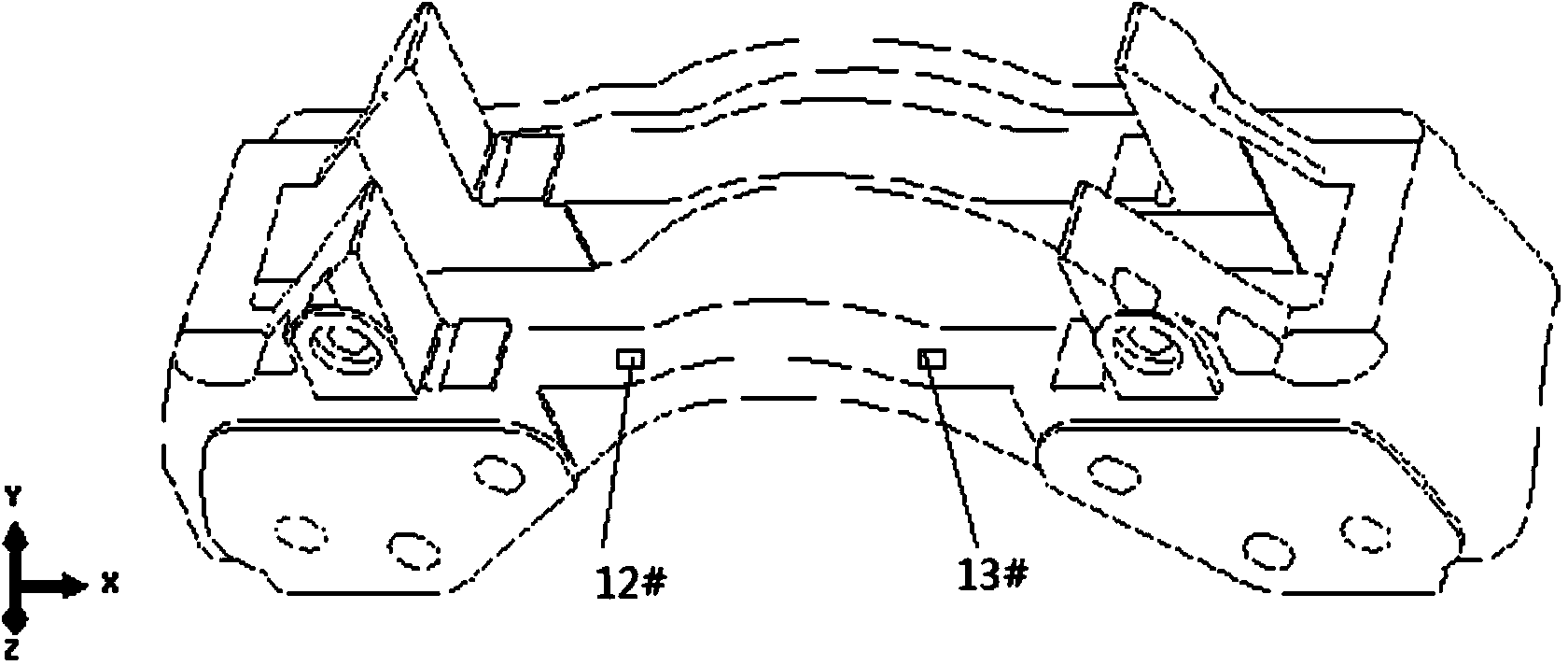

[0027] The first step (S1), firstly, use the PROE software to establish the geometric model of the 24.5-inch disc brake bracket, such as figure 2 As shown, the Hypermesh software is used to generate the tetrahedral mesh model of the bracket, the surface mesh is generated in the four bolt holes below the bracket, and the closed entity is generated from the surface mesh, and the outer length of the entity protruding from the bracket is set as the total length of the bolt protruding Half of the closed entity is divided into a tetrahedral mesh, that is, the tetrahedral mesh of the bolt, then the support and the bolt contact area form a seamless bond and become a whole, such as image 3 shown.

[0028] The second step (S2) is to determine the materials used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com