Machinery constructed to detect deterioration of lubricating oil, reducers for industrial robots, and industrial robots

A technology of lubricating oil and reducer, which is applied in the mechanical field of lubricating oil deterioration sensor, can solve the problems of poor instantaneity, achieve the effect of suppressing the decline of performance and improving the effect of dirt cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

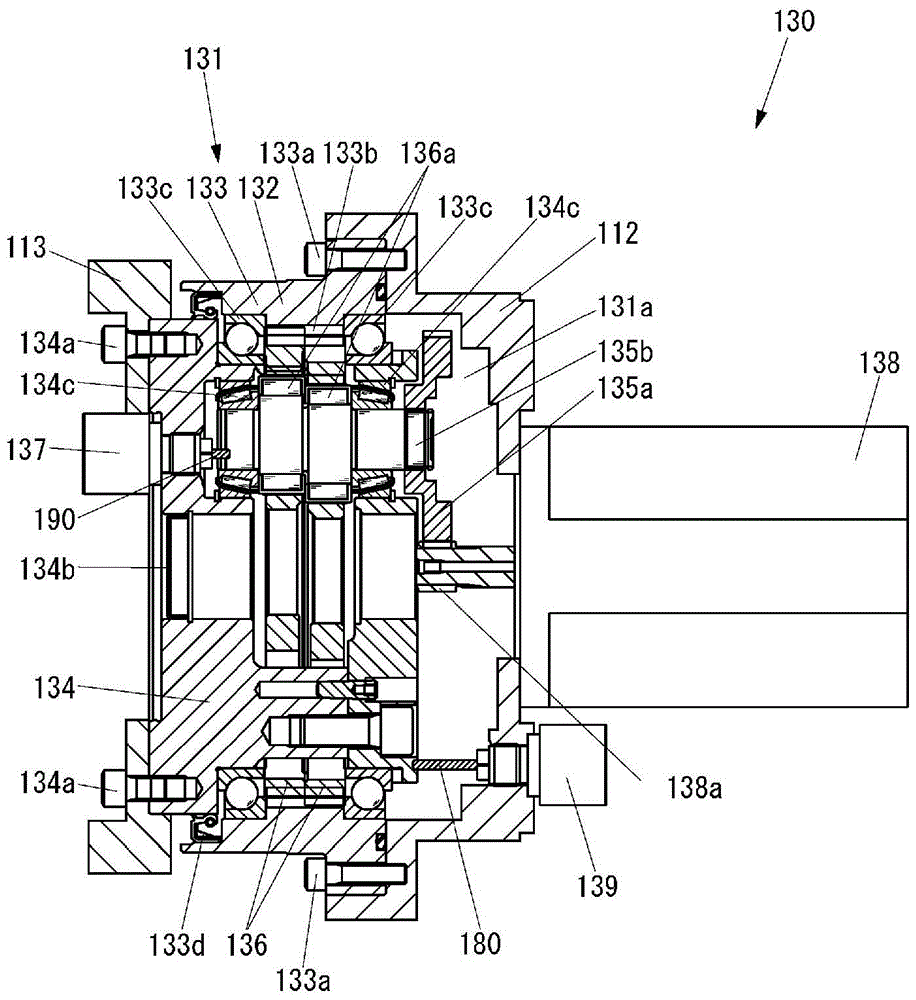

[0078] The inventors of the present application have developed a lubricating oil deterioration sensor capable of instantly determining the type and amount of contaminants in lubricating oil of a machine. This lubricating oil deterioration sensor (hereinafter referred to as "new sensor") is a lubricating oil deterioration sensor that is installed in a machine and detects deterioration of lubricating oil of the machine. The sensor includes a light emitting element that emits light, a colored light receiving element that detects the color of received light, and a gap forming member that forms an oil gap that is a gap into which lubricating oil enters. The gap forming member transmits light emitted from the light emitting element, and the gap for oil is arranged on a light path from the light emitting element to the colored light receiving element.

[0079] However, the inventors of the present application have found that when a new sensor is continuously installed in a machine an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com