Ship model four-freedom-degree rotating arm test device and method

A test device and a technology of degrees of freedom, applied in ship construction, ship design, ship components, etc., can solve the problem that the test and measurement device of the cantilever arm is not easy to be too large, cannot fully predict the maneuverability of high-speed ships and high-center-of-gravity ships, and enlarge the cantilever arm Difficulty in designing test and measurement devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

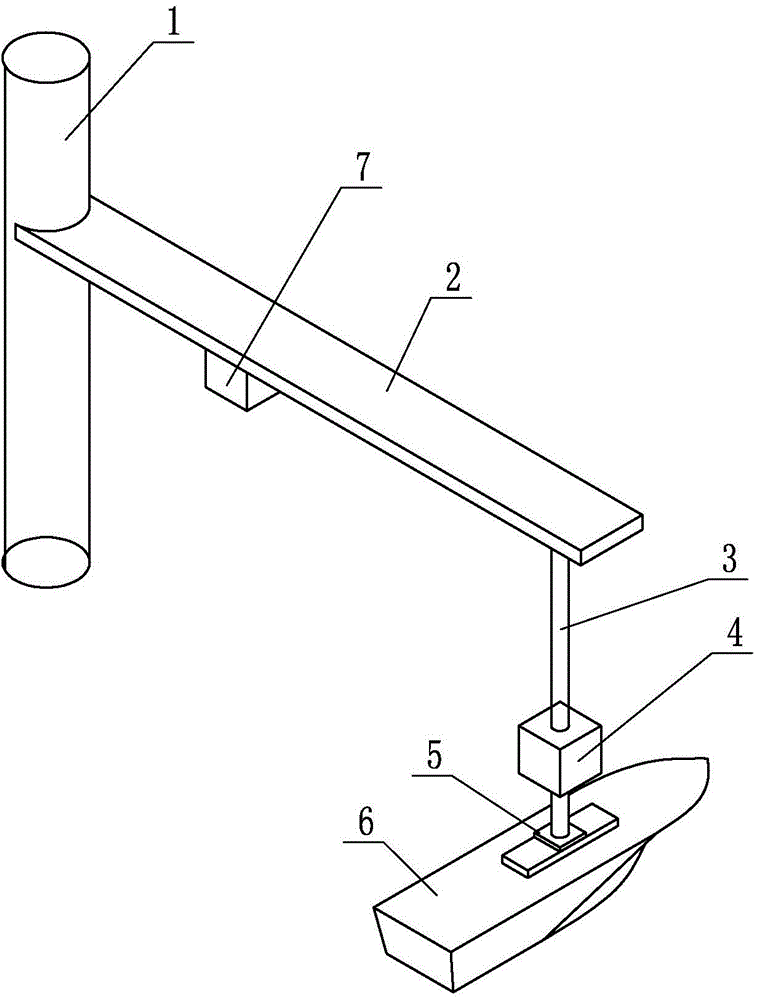

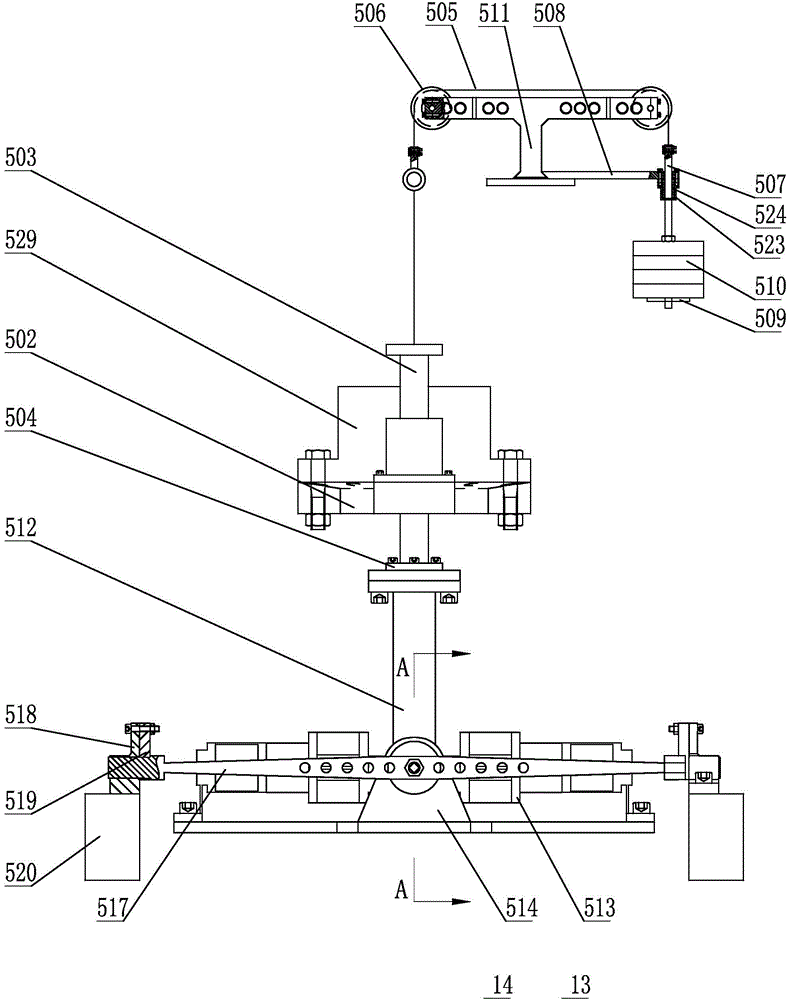

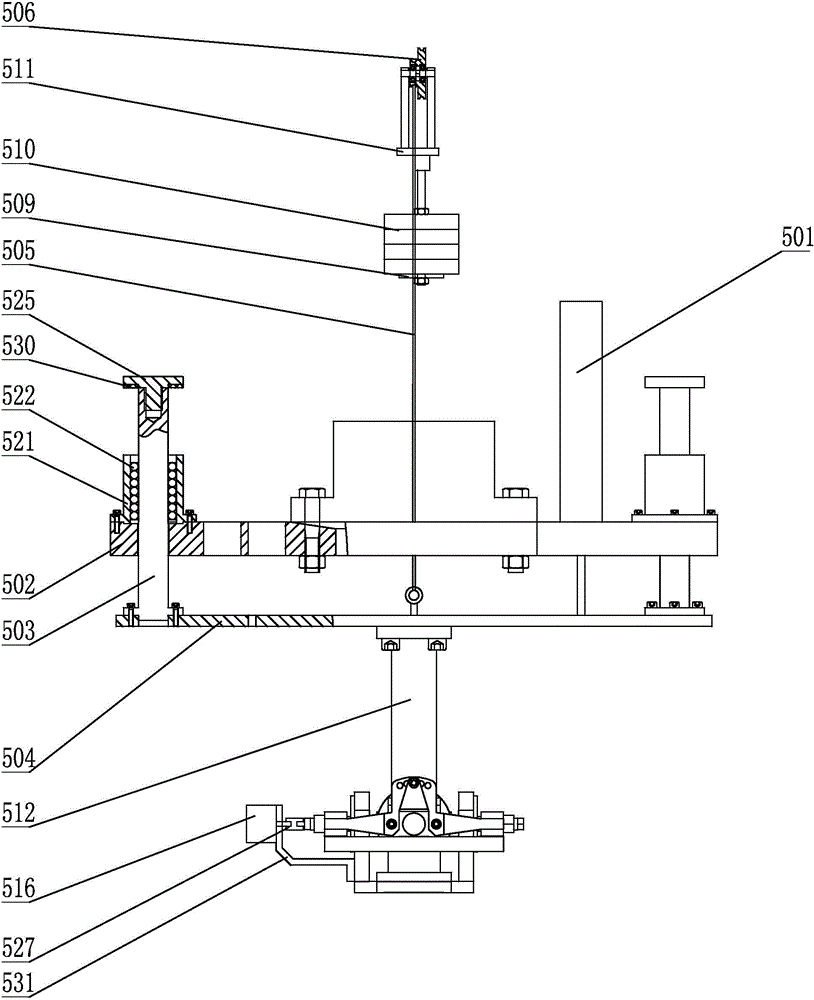

[0029] See figure 1 , the ship model four-degree-of-freedom swing arm test device of the present invention comprises a rotatable swing arm 1, the swing arm 1 is driven to rotate by a motor 7 mounted on the swing arm, and one end of the swing arm 1 is connected to the column 2 in the pool, The other end is connected with the trailer and the drift angle adjustment mechanism 4 through the connecting pole 3, and the measurement mechanism 5 is connected between the trailer and the drift angle adjustment mechanism 4 and the ship model 6, see figure 2 , image 3 , Figure 4 , the measuring mechanism 5 includes an intermediate seat 502 with the trailer and the drift angle adjustment mechanism 4, specifically, the intermediate seat 502 is fixedly connected to the trailer turntable 529, and the heave rod 503 passes through the intermediate seat 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com