Measuring Mechanism in Ship Model Rotary Arm Test

A technology of measuring mechanism and ship model, which is applied in the direction of measuring device, fluid dynamics test, testing of machine/structural components, etc. It is not easy to be too large and other problems, and achieves the effect of compact structure, improved stability, and satisfactory test requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

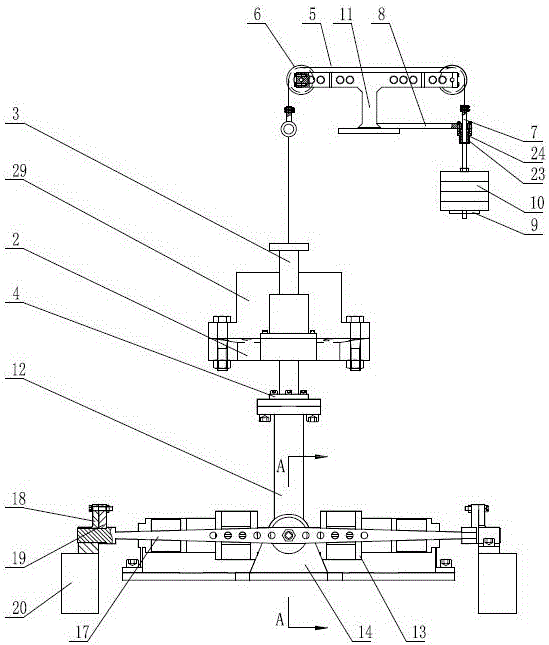

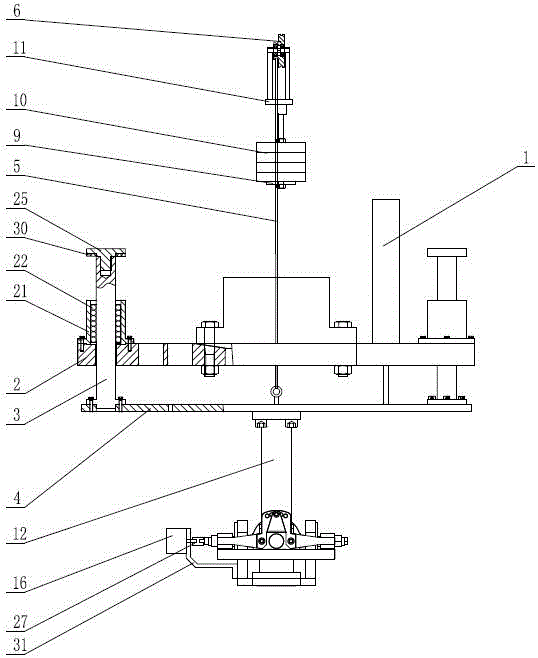

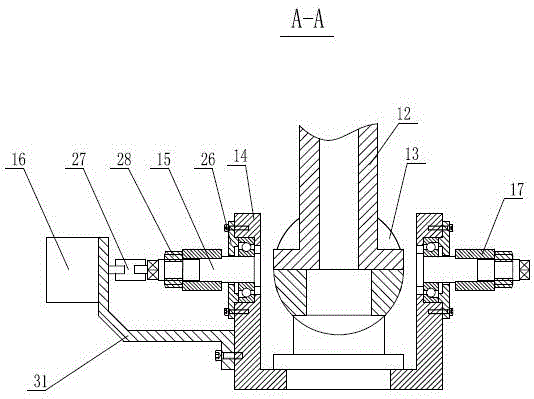

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0021] See figure 1 , figure 2 , image 3 , the present invention includes the middle seat 2 fixedly connected with the swing arm trailer, specifically, the middle seat 2 is fixedly connected with the trailer turntable 29, the heave bar 3 passes through the middle seat 2 and can slide up and down along the middle seat 2, and the heave bar 3 The lower end of the bottom plate is fixedly connected with the bottom plate 4, and the linear displacement sensor 1 is installed on the bottom plate 4. The upper end of the bottom plate 4 is connected with the steel wire rope 5 through the hook and the earring assembly. The rod 7 is connected, the counterweight rod 7 is set in the guide seat 8, the lower end of the counterweight rod 7 is fixed with a tray 9, the tray 9 is used to place the counterweight 10, and at least two pulleys 6 are mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com