Pit well cover with mechanical password locks and cam locking locating

A cam locking, mechanical technology, applied in construction, artificial island, infrastructure engineering, etc., can solve the problems of noise, low safety, poor anti-vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

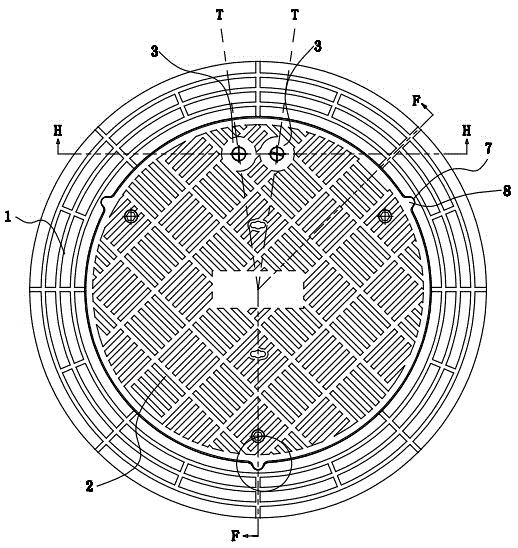

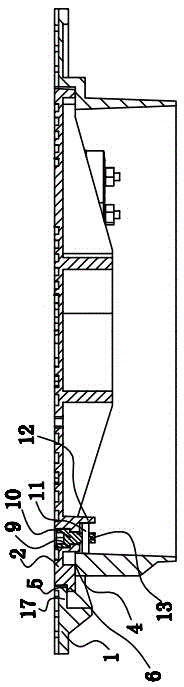

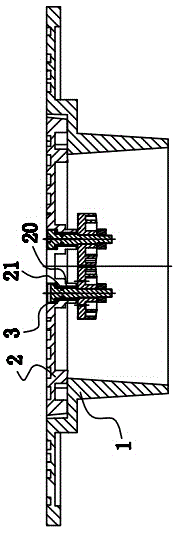

[0021] See attached Figures 1 to 7 , the cellar well cover with mechanical coded lock and cam locking positioning in the figure, including a well cover seat 1, a well cover 2 matched with the inner diameter of the well cover seat 1, and a mechanical coded lock 3 arranged on the well cover 2; wherein: the well cover On the inner wall of seat 1, there is an installation sink platform 4, and the well cover 2 is located on the installation sink platform 4; on the inner wall of the well cover seat 1 above the installation sink platform 4, an inwardly protruding inner boss 17 is arranged, and on the inner boss 17 There are positioning grooves 5 for installation;

[0022] The outer edge wall of the well cover 2 has an outwardly protruding installation and positioning projection 6, and the installation and positioning projection 6 matches the installation and posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com