laser printer

A technology of laser printers and powder cartridges, applied in optics, electrography, instruments, etc., can solve problems such as being easily collided by external forces or other objects, the electrical connection performance of the contact pin 15 being degraded, and the laser printer being unable to be used normally. The effect of increasing stiffness, avoiding deformation or breakage, improving durability and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

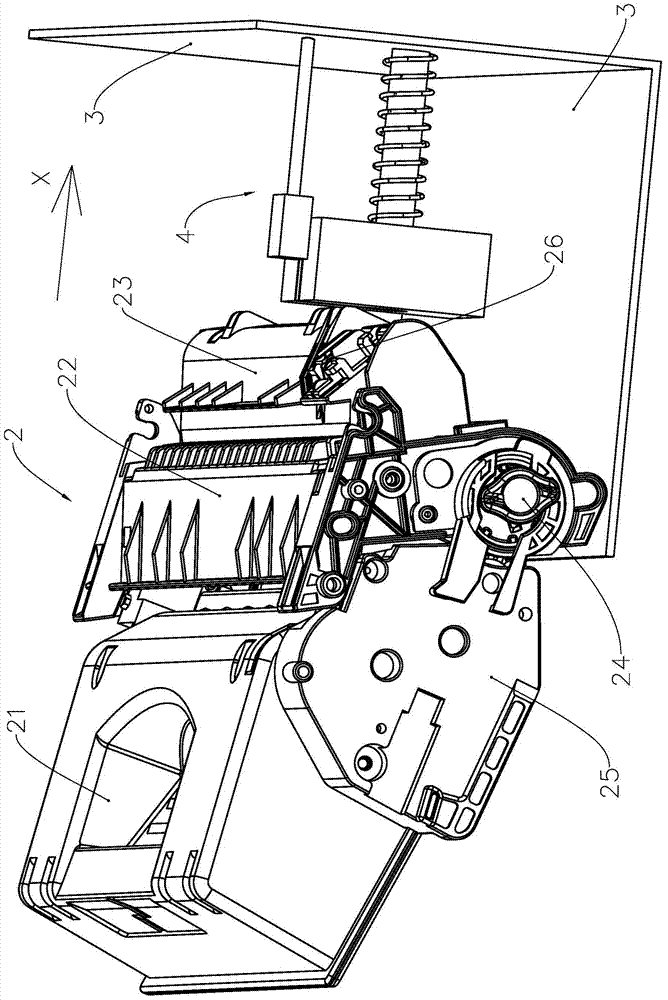

[0037] refer to image 3 , image 3 It is the structure diagram when the powder box 2 and the stylus mechanism 4 cooperate in the laser printer. The process box 2 includes a developing unit 21 and a drum unit 22. The housing of the developing unit 21 encloses a toner accommodating cavity containing carbon powder. A stirring frame, a powder feeding roller, a developing roller and a powder output knife are installed in the toner accommodating cavity. and other components, the shell of the drum unit 22 encloses a waste toner holding chamber 23 containing waste toner, and the waste toner holding chamber 23 is equipped with parts such as a photosensitive drum, a charging roller and a cleaning blade. On one side of the photosensitive drum, a driving force receiver 24 is installed.

[0038] On one side of developing unit 21, side cover 25 is installed, and a plurality of transmission gears are installed in the space between side cover 25 and the casing of developing unit 21, and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap