Method for pulling in restoration pipe, and restored pipeline

A technology for repairing pipes and manholes. It is used in sewer pipeline systems, pipeline laying and maintenance, pipes/pipe joints/fittings, etc. It can solve problems such as reduced load bearing capacity, insufficient drainage capacity, and road subsidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0061] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

[0062] [1] Inspection of drains

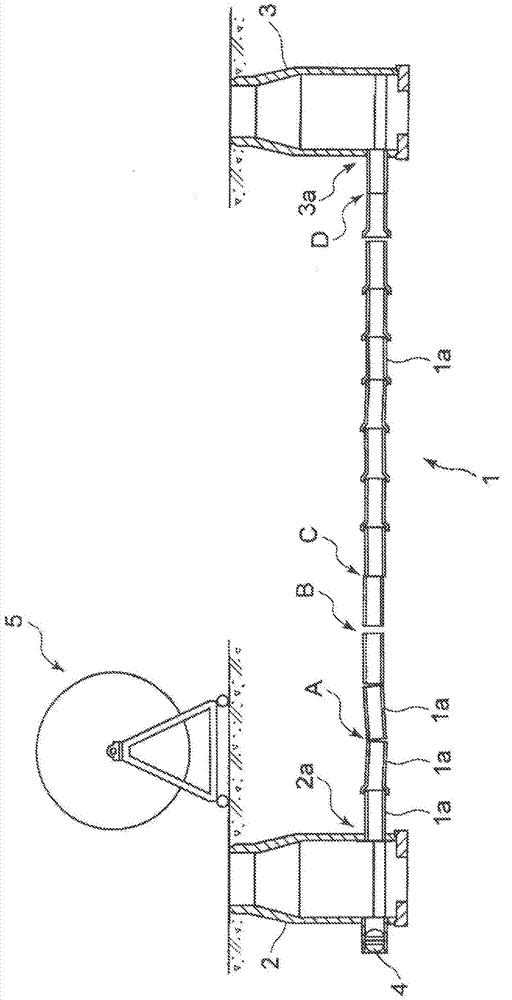

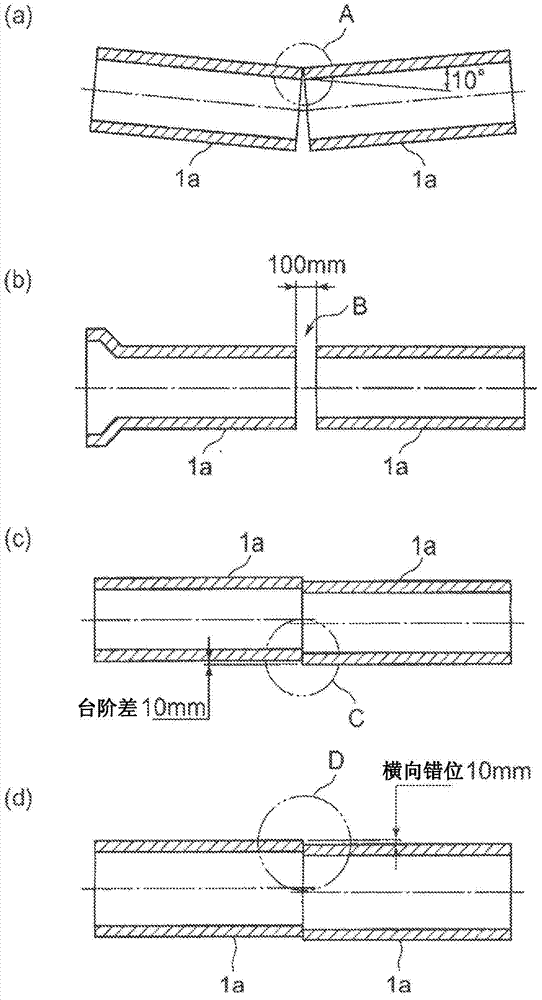

[0063] figure 1 Shown is an aging piped drainage path to which the repair pipe introduction method of the present invention is applied.

[0064] figure 1 Among them, the drainage channel 1 is formed by connecting a plurality of concrete drainage pipes 1a and burying them in soil. One end portion of the drainage passage 1 is connected to, for example, a lower opening portion 2 a provided at a lower portion of the upstream-side access hole 2 . The other end portion of the drainage passage 1 is connected to a lower opening portion 3 a provided at a lower portion of the downstream-side access hole 3 .

[0065] When repairing the above-mentioned drainage channel 1, the inspection of the drainage channel 1 is performed first.

[0066] Specifically, a high-pressure cleaning vehicle is arranged, and the inside of the drainage ...

Deformed example 1

[0157] In Modification 1, the diagnosis process and the excavation process are performed before the simulation introduction process of the first embodiment.

[0158] In the diagnosis process, in order to detect a narrow part in the drainage channel 1 , a diagnostic tool, which will be described later, is passed through the drainage channel 1 . In addition, in the diagnosis process, it is preferable to insert the camera from the rear of the diagnosis tool, and to operate while checking the passing state of the diagnosis tool.

[0159] In the excavation step, an excavator is inserted into the narrow portion in the drainage channel 1 detected by the diagnosis step, and the inner wall of the drainage channel 1 is cut to expand the narrow portion.

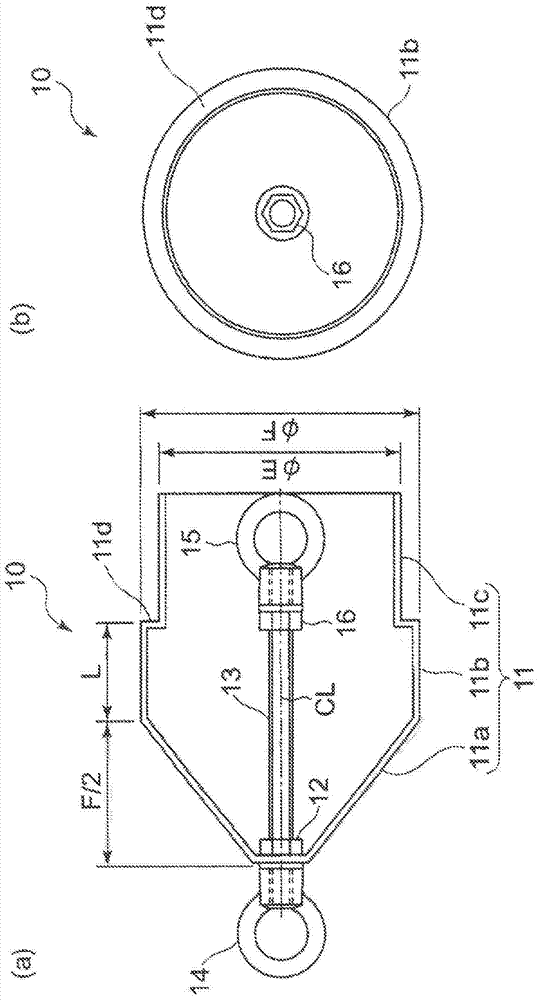

[0160] [1] Diagnostic tool

[0161] Figure 11 It is an external view of the diagnostic tool 60 of the modification 1. FIG. Figure 11 Among them, the diagnostic tool 60 of Modification 1 has a tool body 61 made of an iron or steel m...

Embodiment approach 2

[0187] [1] Inspection of drains

[0188] Figure 13 Shown is an aging piped drainage path to which the pipe repairing method of the present invention is applied.

[0189] Figure 13 Among them, the drainage path 201 is formed by connecting a plurality of concrete drainage pipes 201a and burying them in soil. One end portion of the drainage passage 201 is connected to, for example, a lower opening portion 202a provided at the lower portion of the inspection hole 202 on the most upstream side. The other end portion of the drainage passage 201 is connected to a lower opening portion 203 a provided at the lower portion of the downstream side access hole 203 .

[0190] When repairing the above-mentioned drainage channel 201, an inspection of the drainage channel 201 is performed first.

[0191] Specifically, a high-pressure cleaning vehicle is arranged in the vicinity of the manhole 203 on the downstream side, and the inside of the drainage passage 201 is cleaned with high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com