Lens device for surveillance camera

A camera and lens technology, which is applied in the field of lens devices for surveillance cameras, can solve the problems of single-sided blurred optical performance, bending of the main body of the lens barrel, and influence, and achieve the effects of reliable locking, easy locking operation, and easy locking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

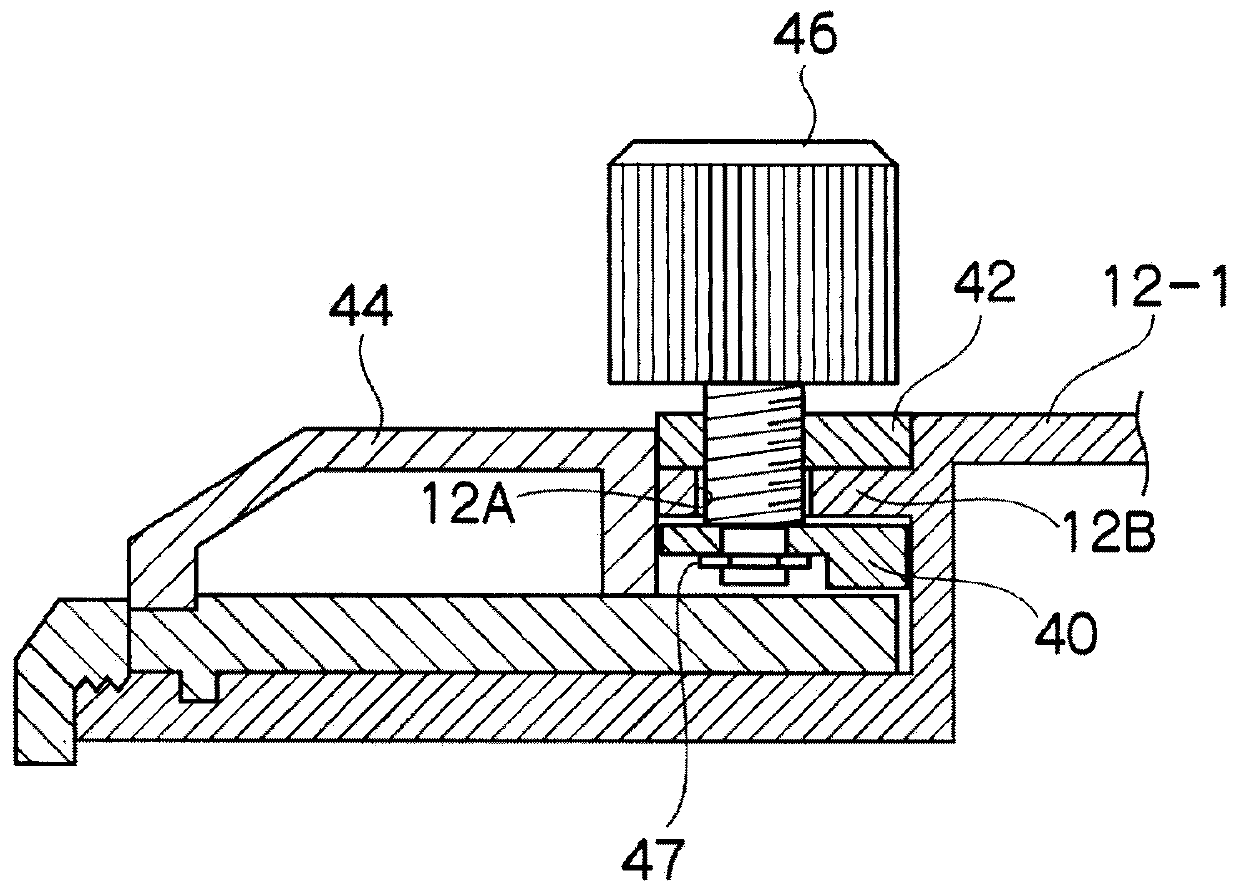

[0083] In this embodiment, a protrusion 12B is formed on the first lens barrel main body 12-1, and a hole 12A through which the locking knob 46 can penetrate is formed on the protrusion 12B. However, the first lens barrel main body 12- 1 is formed with a threaded hole for screwing the locking knob 46.

[0084] Picture 11 It is a modified example in which a threaded hole for screwing the lock knob 46 is formed in the first lens barrel main body 12-1' (fixed barrel). It should be noted that the same reference numerals are given to the same parts as in the present embodiment, and the description thereof will be omitted.

[0085] A screw hole 12D is formed in the protrusion 12B of the first lens barrel main body 12-1'. The screw direction of the screw hole 12D is opposite to the screw direction of the screw hole 42B. In this embodiment, a right-hand thread is applied to the threaded hole 42B, and therefore, the threaded hole 12D is a left-hand thread.

[0086] The lock knob 52 (lock ...

Deformed example 2

[0089] In this embodiment, the focus ring 14 is locked by making the brake member 40 and the brake ring 42 contact the focus ring 14 with their faces, respectively. However, even if the brake member 40 and the brake ring 42 do not face the focus ring 14. The abutment of the ring 14 can also lock the focus ring 14.

[0090] In addition, when the lock knob 46 is tightened too much and the brake member 40 is deformed and warped in the longitudinal direction due to changes in time, it is considered that the brake member 40 and the focus ring 14 may not face each other. It is the case where two lines (two points when viewed in the cross section) are in contact. In addition, when the brake ring 42 is formed of a material that hardly deforms, such as metal, it is considered that the brake ring 42 and the focus ring 14 are not in a plane but in a line (a point when viewed in a cross section). The contact situation.

[0091] Picture 12 It is a modified example in which the brake member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com