Rotational stirring device provided with multiple reaction kettles and stirring method

A technology of rotary stirring and reaction kettle, applied in mixers with rotary stirring devices, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of inconvenient cleaning and maintenance, and high equipment cost , to achieve the effect of convenient cleaning and maintenance, reducing equipment cost and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

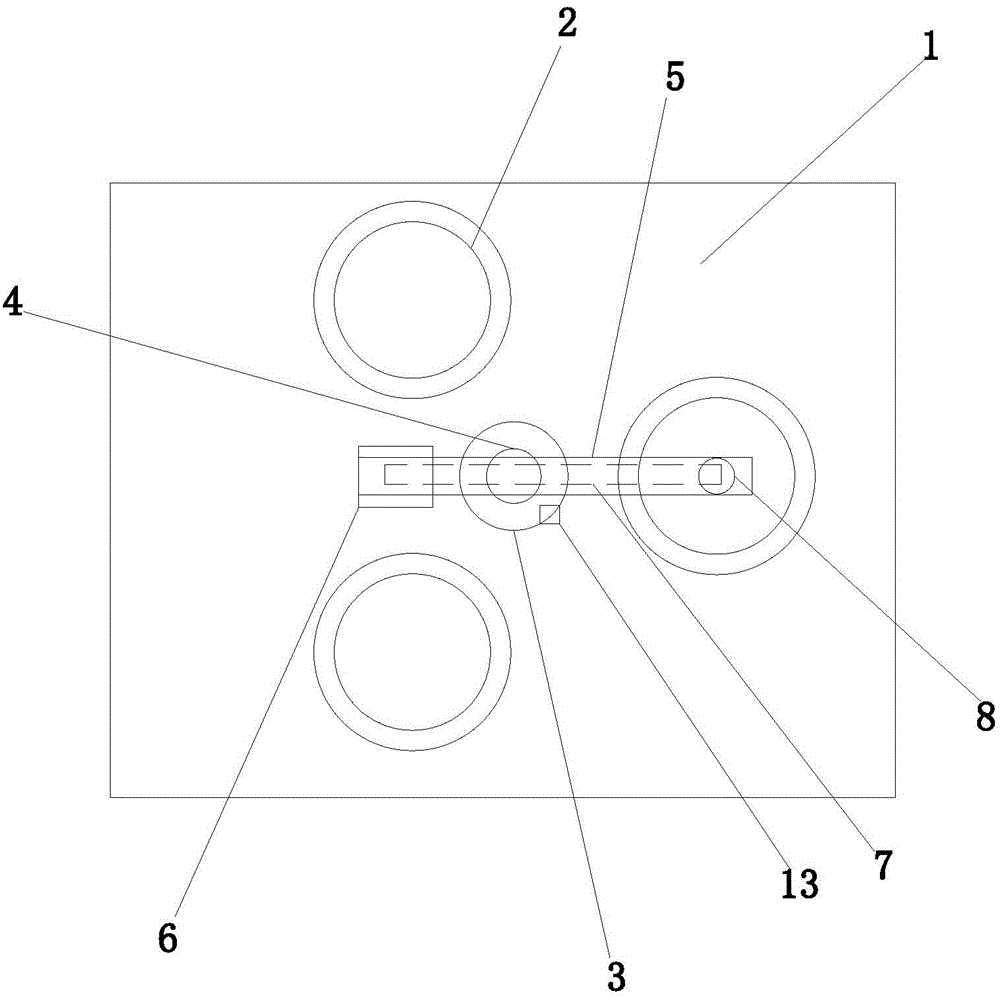

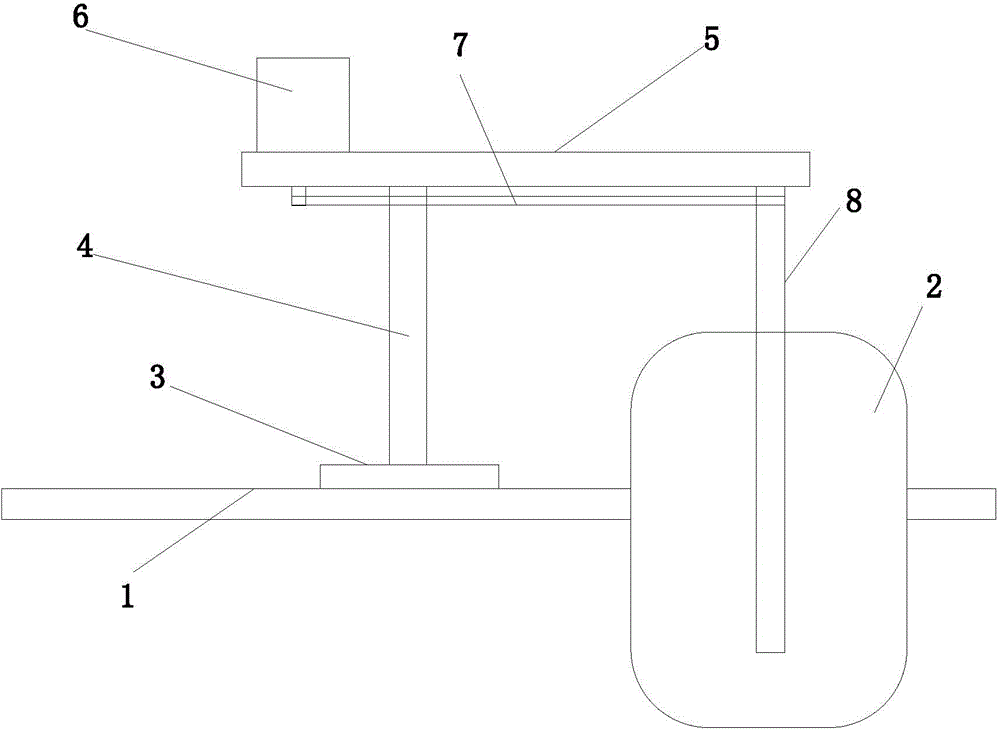

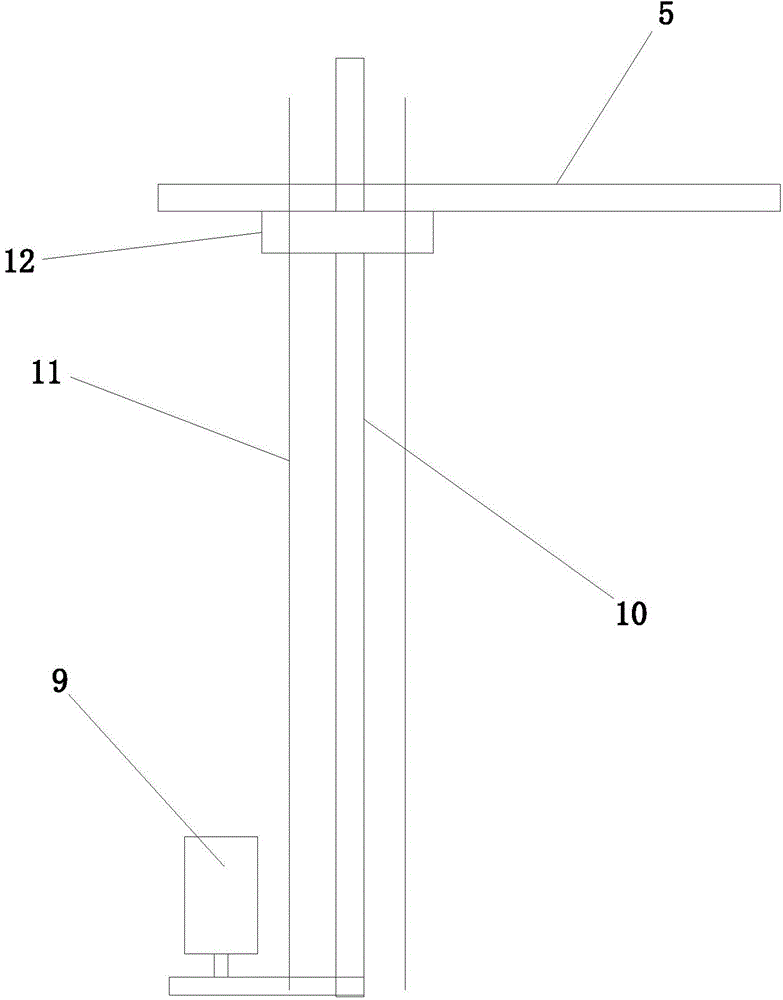

[0016] Example. A plurality of reactor rotating stirring devices, constituted as Figure 1-3 As shown, it includes a reaction platform 1, three reactor bodies 2 are uniformly arranged on the reaction platform 1 in the circumferential direction, and there is a rotating disk 3 in the center of the three reactor bodies 2, and the rotating disk 3 is provided with a lifting mechanism 4, and the lifting mechanism 4 The upper end of the cantilever beam 5 is provided with a cantilever beam 5, and one end of the cantilever beam 5 is provided with an agitator 6 arranged downward, and the other end is provided with a motor 6, and the motor 6 is connected with the agitator 8 through a chain 7.

[0017] Described elevating mechanism 4 is a hydraulic cylinder; Or described elevating mechanism 4 comprises the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com