Plastic round pipe cutting device

A round pipe and plastic technology, which is applied in the field of plastic round pipe cutting devices, can solve the problems of uneven section of PE pipe, deep buried underground, affecting the quality of welding work, etc., and achieve the effect of flat cut section and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

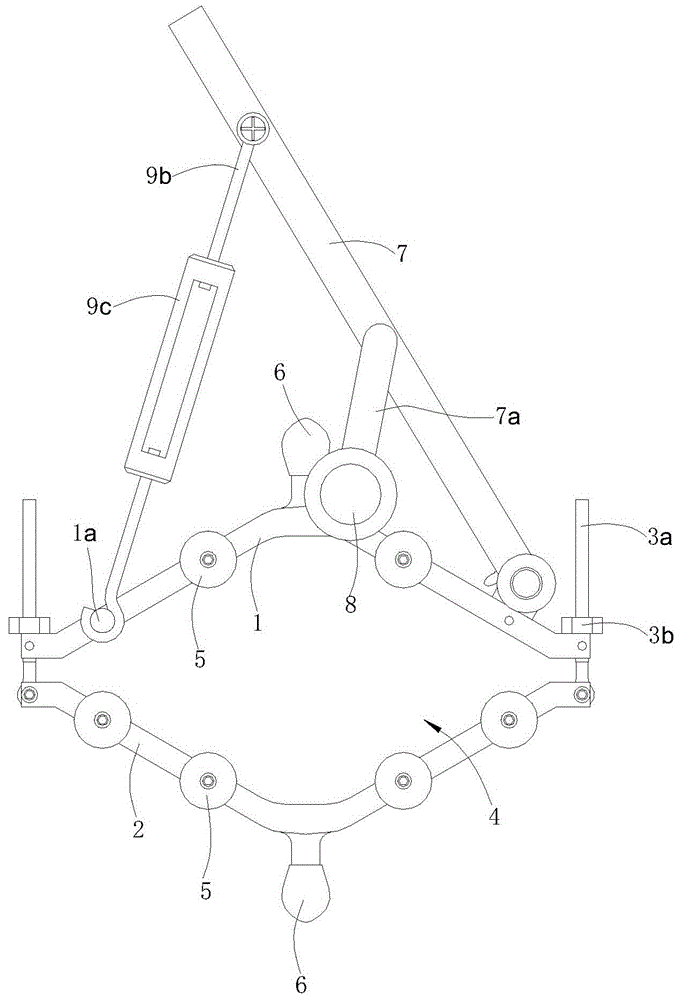

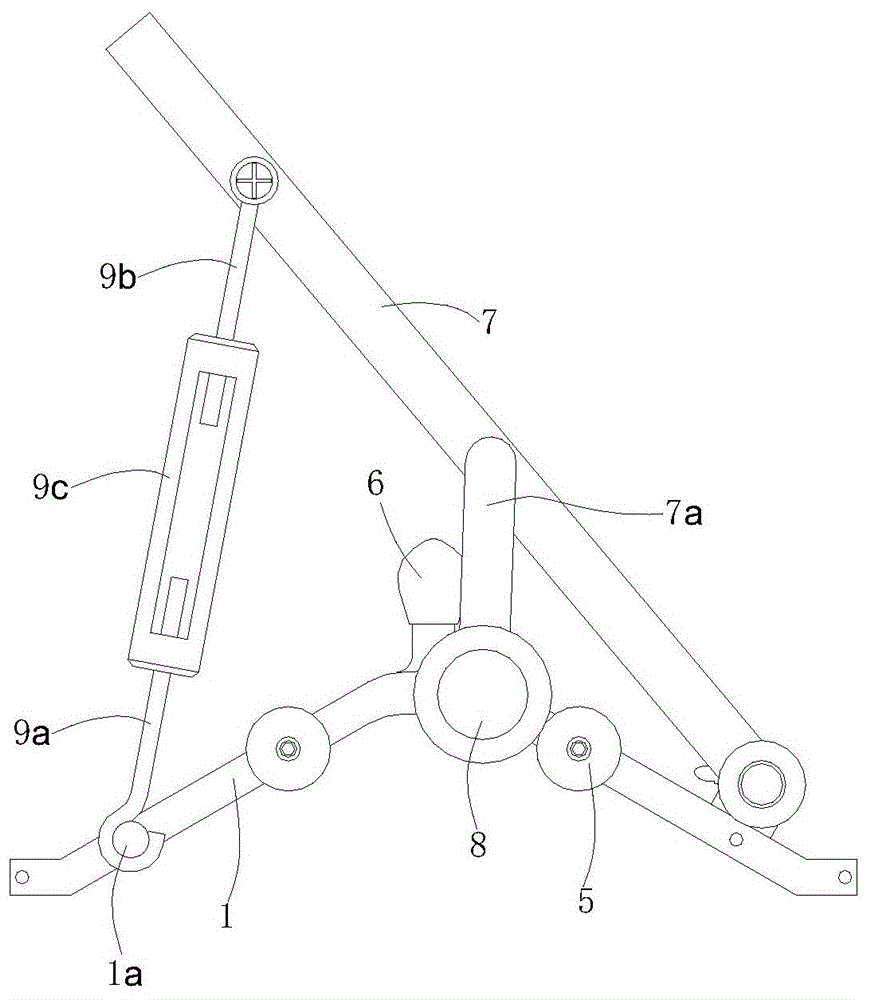

[0018] Such as figure 1 shown

[0019] The device includes clamp fixing components and cutting adjustment components;

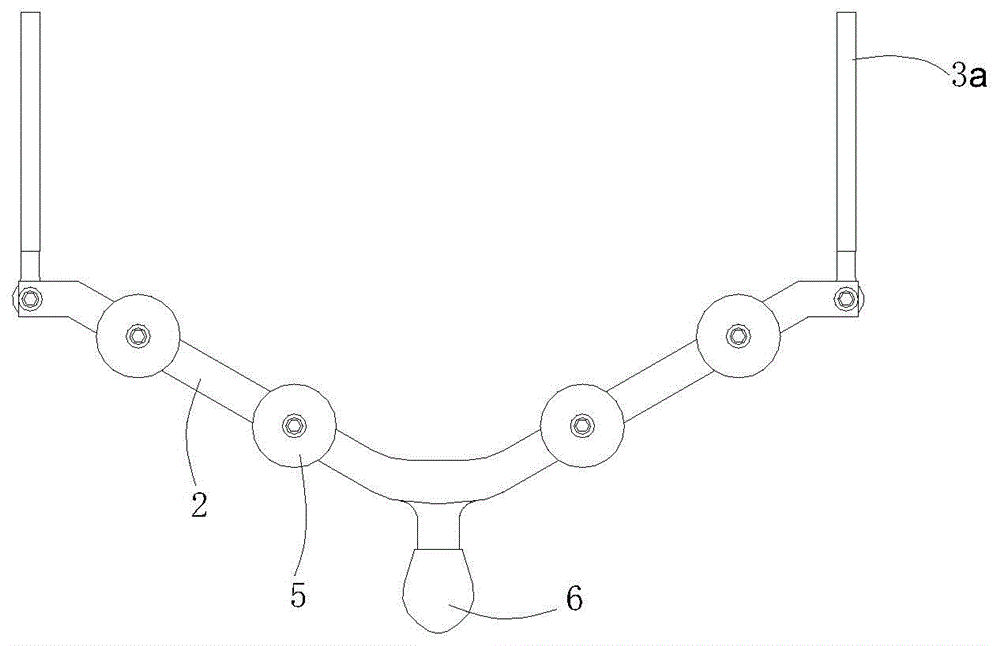

[0020] Such as Figures 2 to 3 shown

[0021] The clamp fixing assembly includes two arc-shaped support seats, the two arc-shaped support seats are respectively an upper support seat 1 and a lower support seat 2, the upper support seat 1 and the lower support seat 2 are connected end to end, and the upper support seat 1 and the two ends of the lower support base 2 are respectively connected by two fixed screw rods. The fixed screw rods include a rod body 3a and a fixed nut 3b. There is a working gap 4 between the upper support base 1 and the lower support base 2. The upper support base 1 is close to Two sliding wheels 5 are installed on the edge of the working gap 4, and four sliding wheels 5 are installed on the lower support seat 2 near the edge of the working gap 4. The rotation axes of all the sliding wheels 5 have the same direction. The surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com