Reamer for implant surgery

一种扩孔钻、移植术的技术,应用在手术、植牙、牙修补术等方向,能够解决难以实现排出、切削效率低下、旋转干扰等问题,达到提高切除力和作业速度、提高切除力和作业性、降低摩擦阻抗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

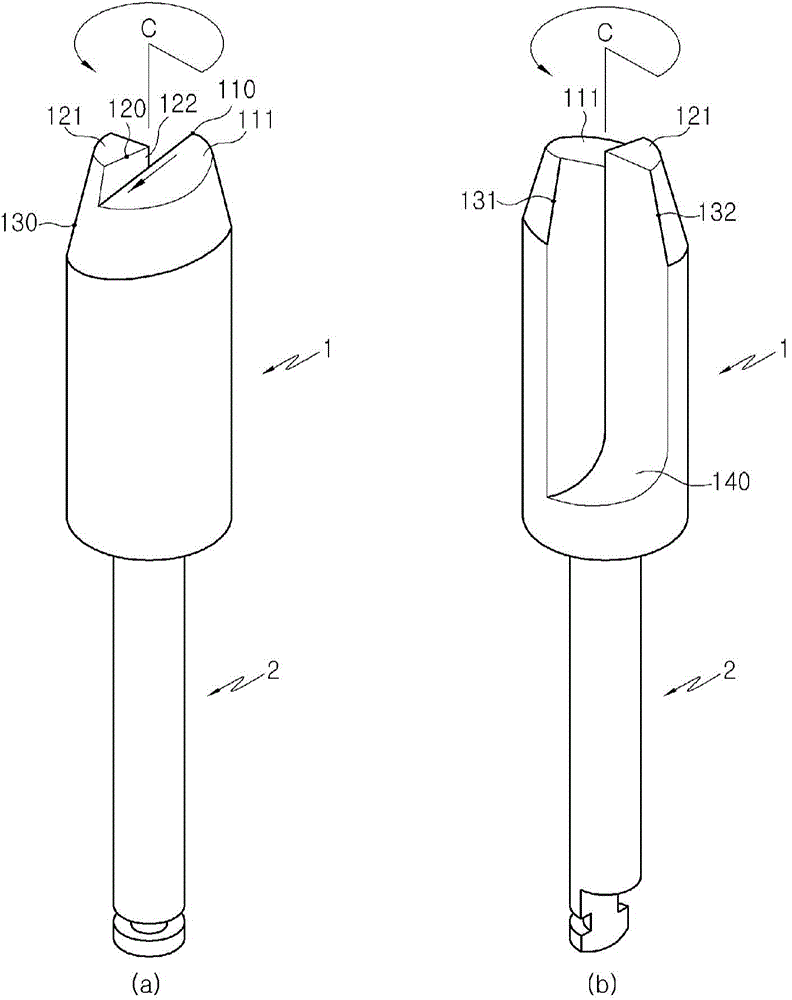

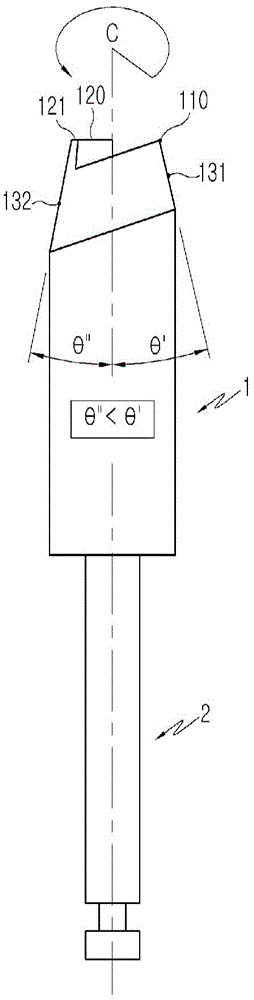

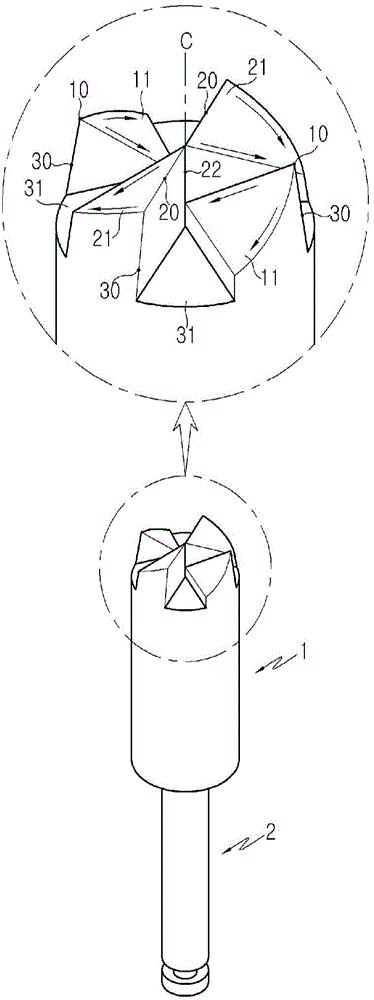

[0043] Below, the technical structure and effect of the preferred embodiment that can realize the purpose of the present invention will be described with reference to the accompanying drawings. The technical structure of the present invention has been patented in Korea by the applicant and inventor "An Changxun" who has utilized and improved the present invention After a part of the technical composition of "Cutting Lifting Reaming Drill for Maxillary Sinus Transplantation (Korean Patent No. 10-0792649)", a new structure was added to achieve more advanced effects than before. figure 1 , 2 A conventional reamer for transplantation (Korean Patent No. 10-0792649) shown in .

[0044] figure 1 , 2 It is the existing cross-sectional view and front view of the reamer used for transplantation equivalent to Korean Patent No. 10-0792649, such as figure 1 , as shown in 2, the existing transplant reamer, as a cutting and lifting reamer for transplantation, includes: in order to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com