Template positioning apparatus and template positioning method

A positioning device and template technology, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems that affect the inspection accuracy of parts and tooling molds, tooling mold inspection accuracy and efficiency, and the installation efficiency and accuracy of complete sets of cutting surface templates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

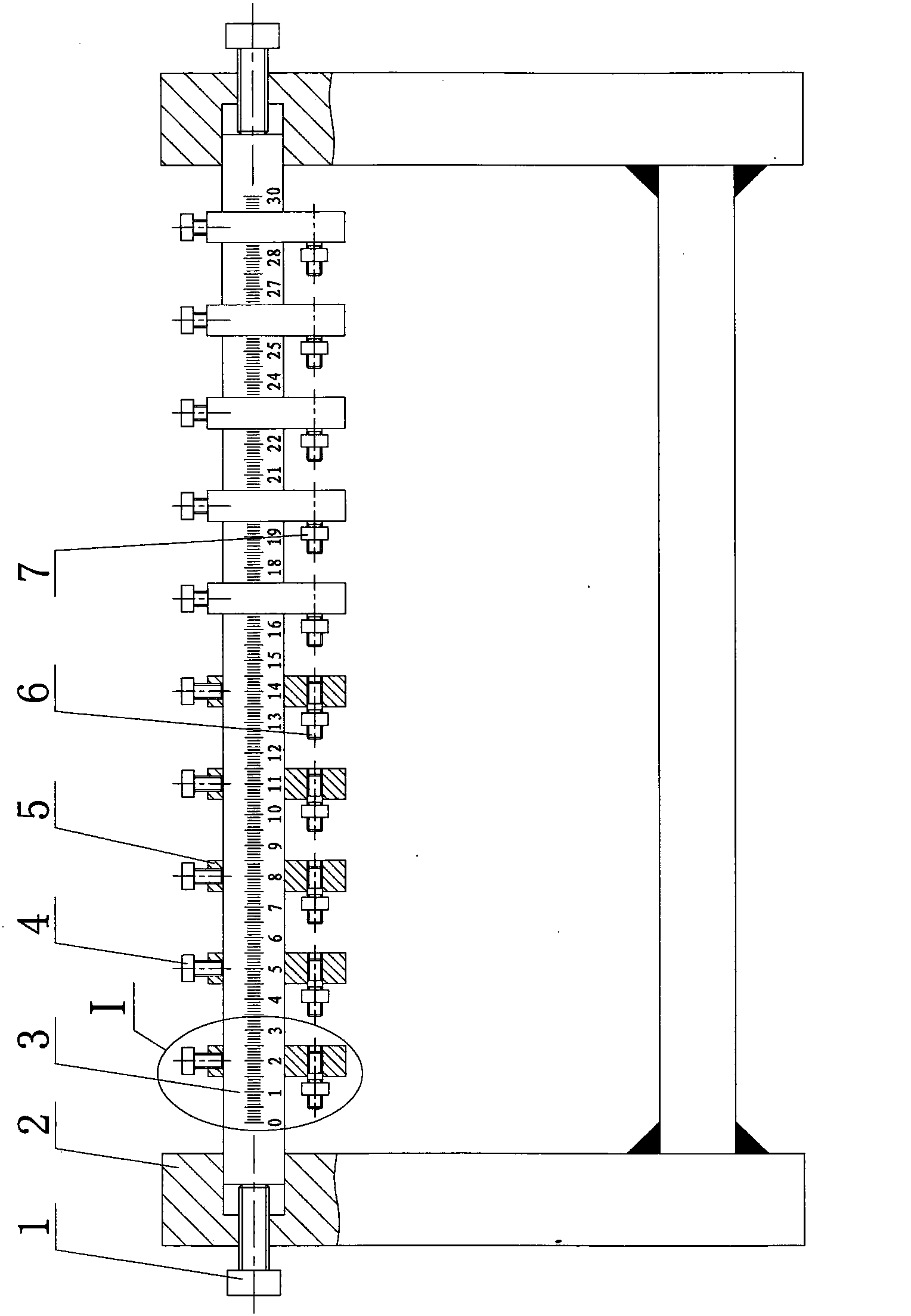

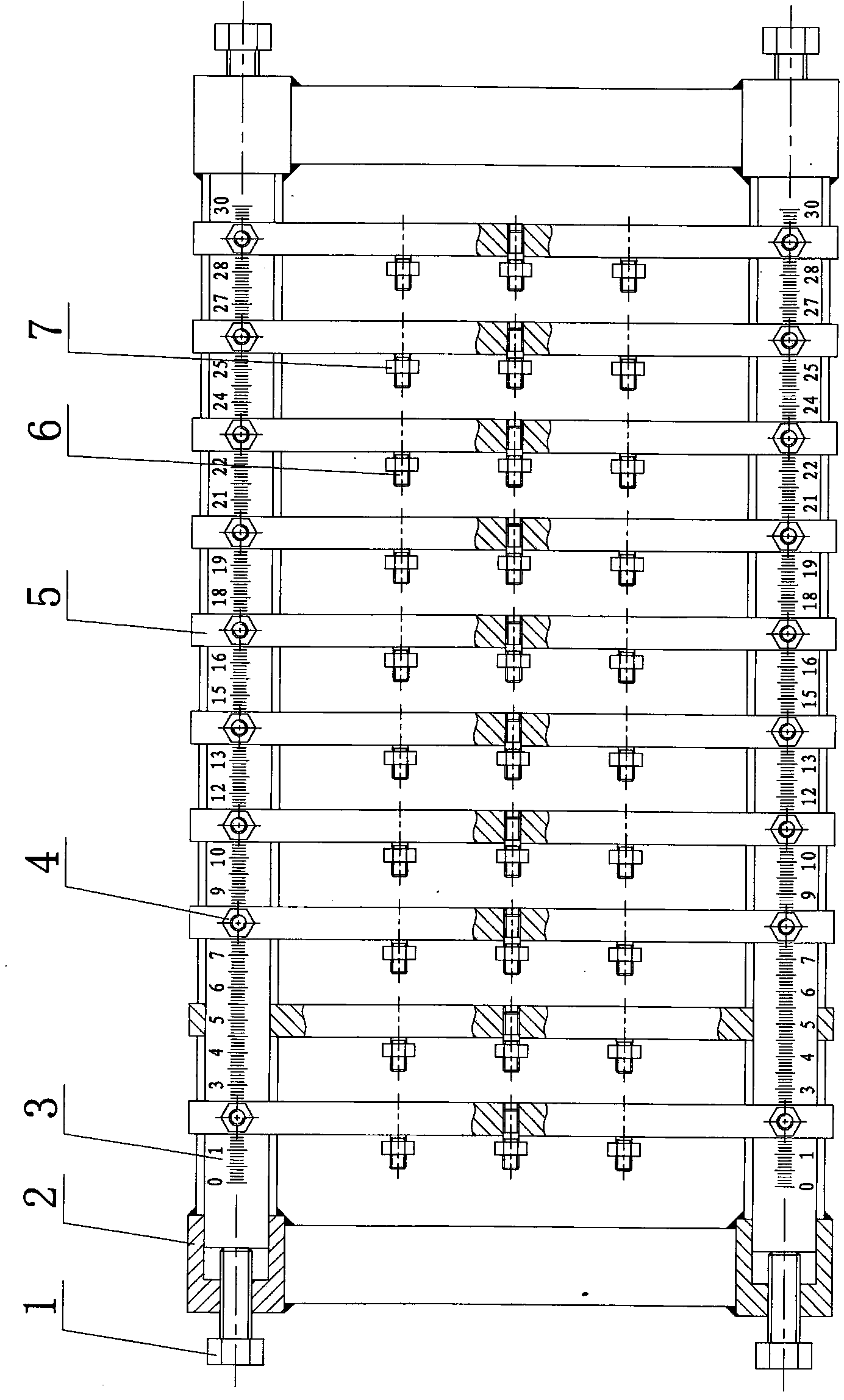

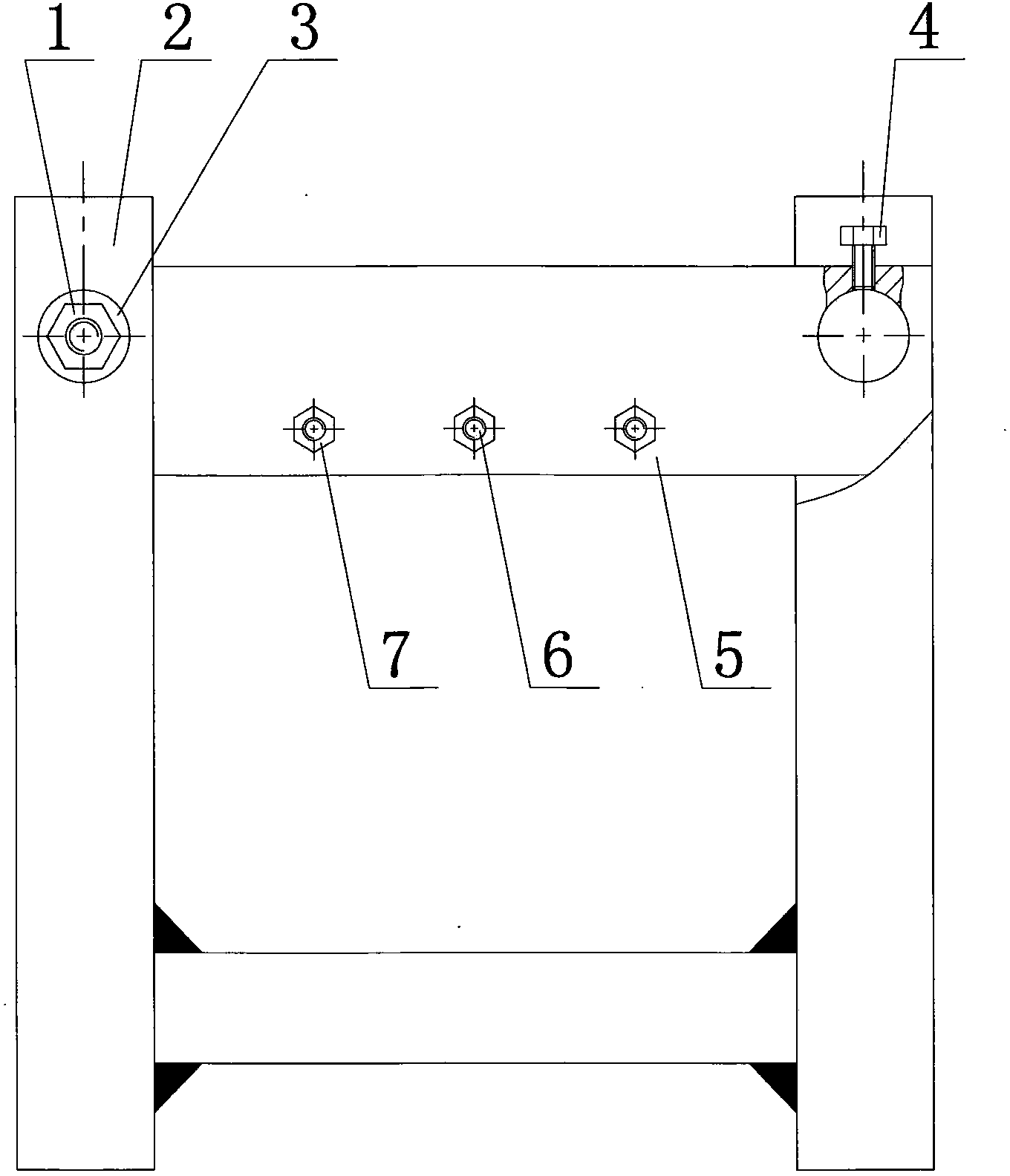

[0016] Such as Figure 1 to Figure 4 As shown, a sample positioning device, the support 2 is a rectangular frame structure with uprights, and symmetrical blind holes are arranged on the inner side of the uprights corresponding to every two positions of the support 2, and the blind holes are provided with cross supports The scale guide rod 3 of the seat 2 is provided with adjustment bolts 1 at both ends of the scale guide rod 3, and the inner end faces of the adjustment bolts 1 pass through the corresponding outer walls of the blind holes respectively, and are respectively pressed against the end faces of the scale guide rod 3, Thereby, the scale guide rod 3 is limited in the axial direction; the scale guide rod 3 has a scale line and a scale value, and the outer circumferences of the two scale guide rods 3 are jointly connected with several mobile hangers 5 arranged in parallel, Vertical locking bolts 4 are arranged above the two ends of the mobile hanger 5, and the locking bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com