Electro-hydraulic combined braking system with electric power function and applicable to regenerative braking automobile

A technology of regenerative braking and electric power assist, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve problems such as disadvantage, long pressure build-up time, increase system complexity and cost, and reduce manufacturing costs and pressure fluctuations. The effect of small size and high pressure regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

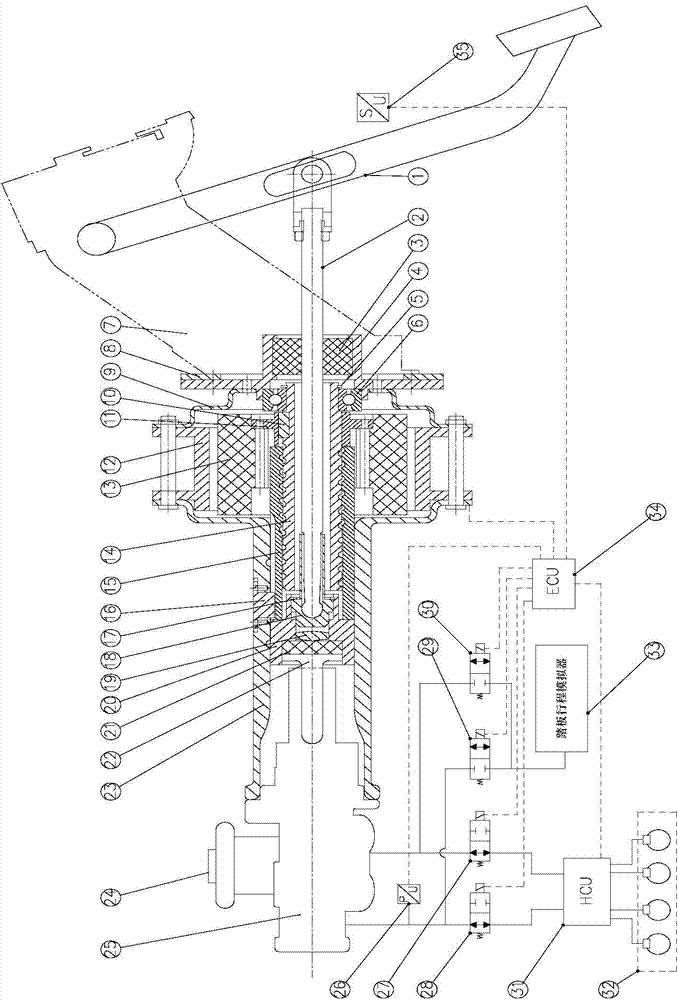

[0040] The present invention has the function of electric brake boosting and is applicable to the electro-hydraulic composite braking system with the regenerative braking function of automobiles, such as figure 1 As shown, it includes an electric brake booster device, a brake pedal assembly, a hydraulic control system, a sensor assembly, an electronic control unit 24 , and a pedal stroke simulator 33 .

[0041] The electric brake boosting device includes a hollow motor, a ball screw pair, a push plate 20 , a reaction plate 21 , a reaction plate push block 18 , and a push rod 22 .

[0042] Wherein, the front end and the rear end of the hollow motor are respectively fixed with a front end cover 23 and a rear end cover 9 by bolts; the front end cover 23 and the rear end cover 9 are fixed to the stator 12 of the hollow motor by bolts. There is an integrated sleeve on the front end cover 23; a through hole is opened in the center of the rear end cover 9; and the sleeve and the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com