Blowing rate adjusting device of railway vehicle

A rail vehicle and air volume technology, which is applied in the heating/cooling of railway vehicles, transportation and packaging, railway car body parts, etc., and can solve the problem that passengers cannot adjust the air outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

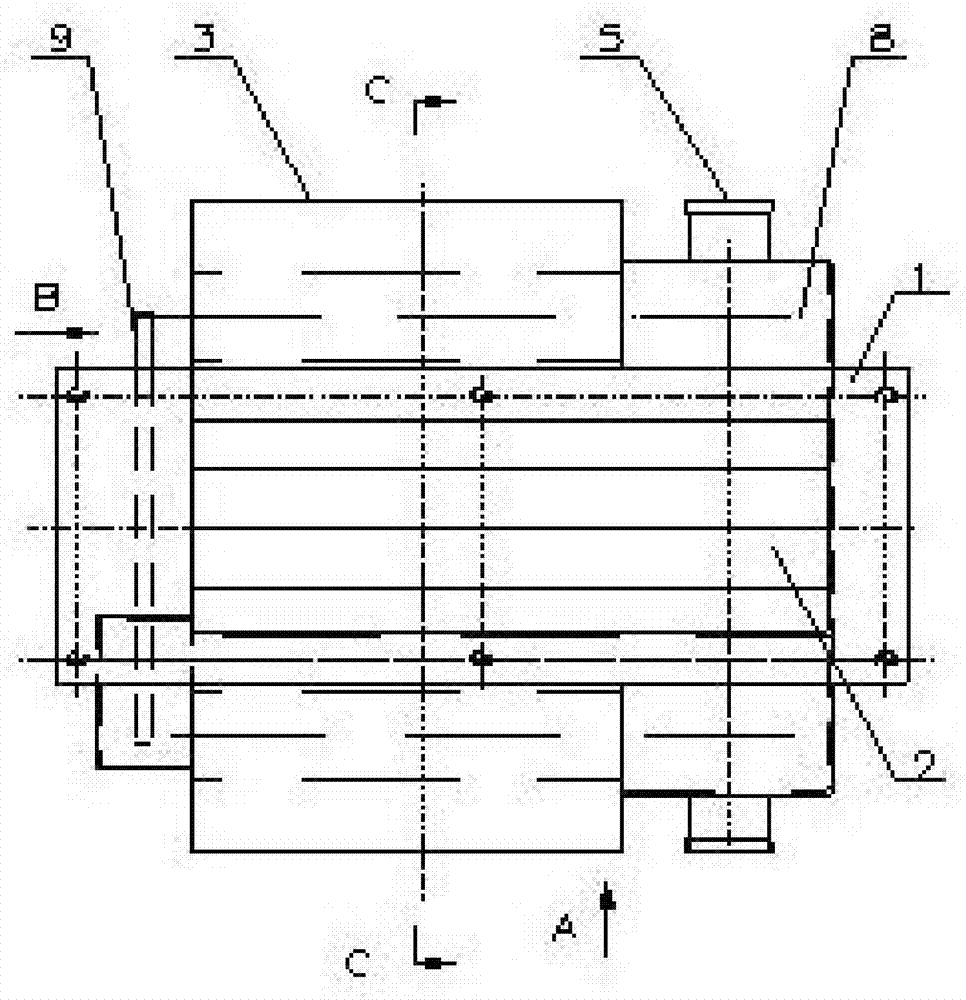

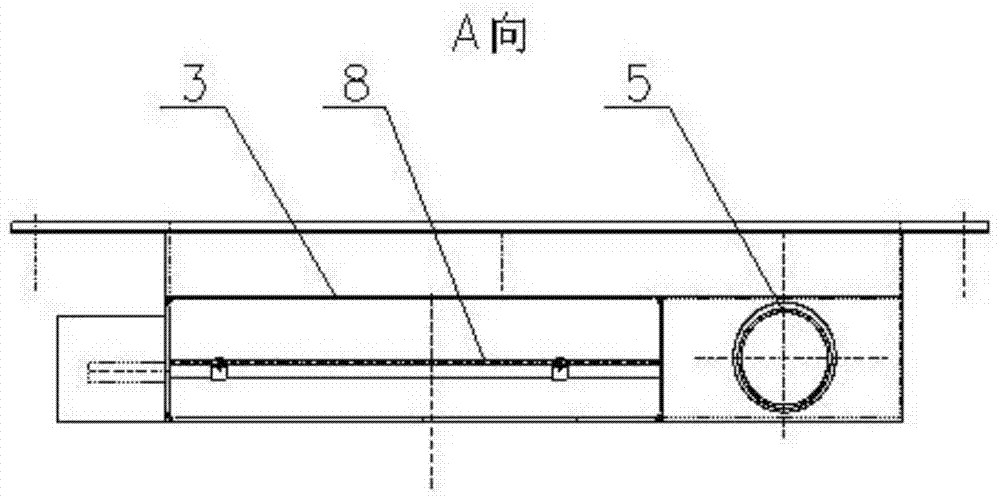

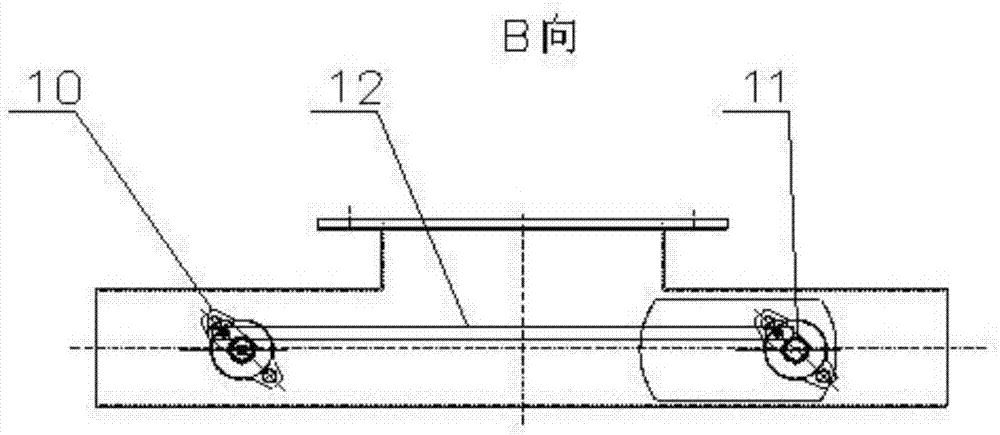

[0023] Such as figure 1 and figure 2 As shown, the present invention provides a rail vehicle air volume adjustment device, comprising a tuyere body 1, at least one air inlet 2 and an air outlet 3 are opened on the tuyere body 1, and the air inlet 2 is opened on the top of the tuyere body 1 and the air conditioning unit. The air supply duct (not shown in the figure) is connected, and the air supply duct is arranged along the longitudinal length of the car body. The air outlet 3 is sent into the compartment to adjust the ambient temperature in the compartment.

[0024] For high-grade trains equipped with independent private rooms such as soft sleepers, air outlets 3 are provided in each private room. In this embodiment, the air outlet body 1 is arranged longitudinally or transversely along the car body, and is symmetrically arranged on both sides of the air outlet body 1. There are two air outlets 3, and the air processed by the air conditioning unit flows out from the air ou...

Embodiment 2

[0032]The difference from Embodiment 1 is that when the area of the private room is large and the distance between the two air outlets 3 is relatively far, or when the two air outlets 3 are correspondingly installed in different private rooms, the symmetrically arranged two air outlets 3 They are not connected through the link mechanism 9, but are independently controlled. Each rotating shaft 8 is connected to a stepping motor, and each air outlet 3 can be provided with a set of control devices for independent control. Other structures and control methods are the same as in Embodiment 1. same.

Embodiment 3

[0034] The difference from Embodiment 1 is that each compartment is provided with an air outlet 3, the air outlet body 1 is no longer provided with a deflector 4, and a bypass air outlet 5 is provided next to the air outlet 3. Other structures and control methods Same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com