Yoghurt cup sheet raw material and preparation method thereof

A technology for yogurt cups and raw materials, applied in the field of synthetic resins, can solve the problems of complex blending of HIPS and rubber, failure to meet the sensory needs of consumers, easy occurrence of macula, black spots, etc., and achieve excellent appearance and good rigidity , good impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

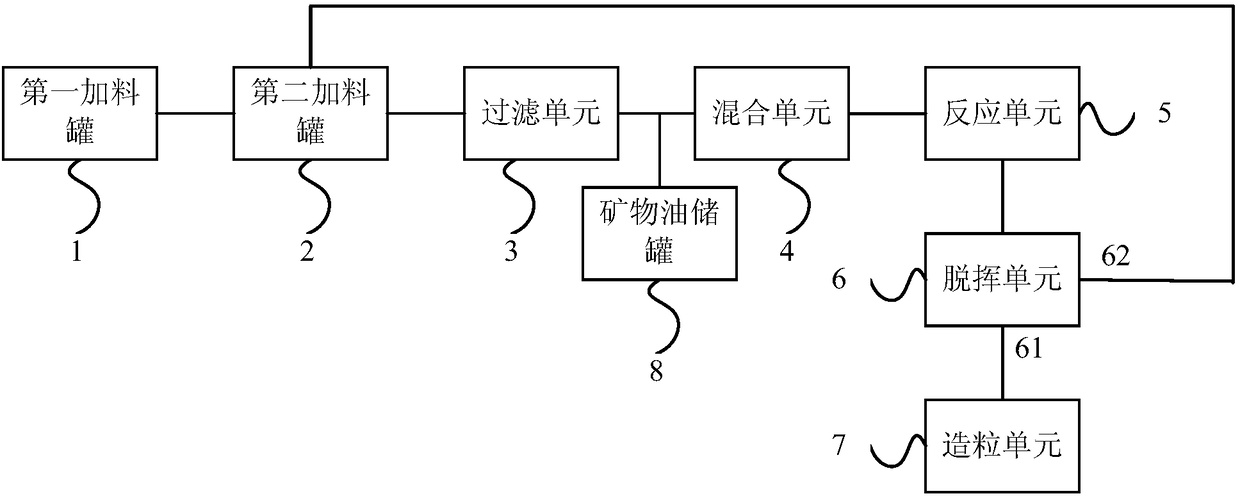

[0043] This embodiment provides a kind of equipment for preparing yogurt cup sheet material, figure 1 For the schematic diagram of equipment for preparing yogurt cup sheet material provided by the embodiment of the present invention, please refer to figure 1 , the equipment includes a first feeding tank 1, a second feeding tank 2, a filtering unit 3, a mixing unit 4, a reaction unit 5, a devolatilization unit 6 and a granulation unit 7 connected in sequence; the connection between the filtering unit 3 and the mixing unit 4 The connecting pipeline between them is also communicated with the mineral oil storage tank 8; the devolatilization unit 6 includes a polymer output port 61 and a volatile matter output port 62, the polymer output port 61 communicates with the granulation unit 7, and the volatile matter output port 62 communicates with the second The feeding tank 2 is connected.

[0044] Wherein, the filter unit 3 includes two filters connected in series, i.e. a primary fil...

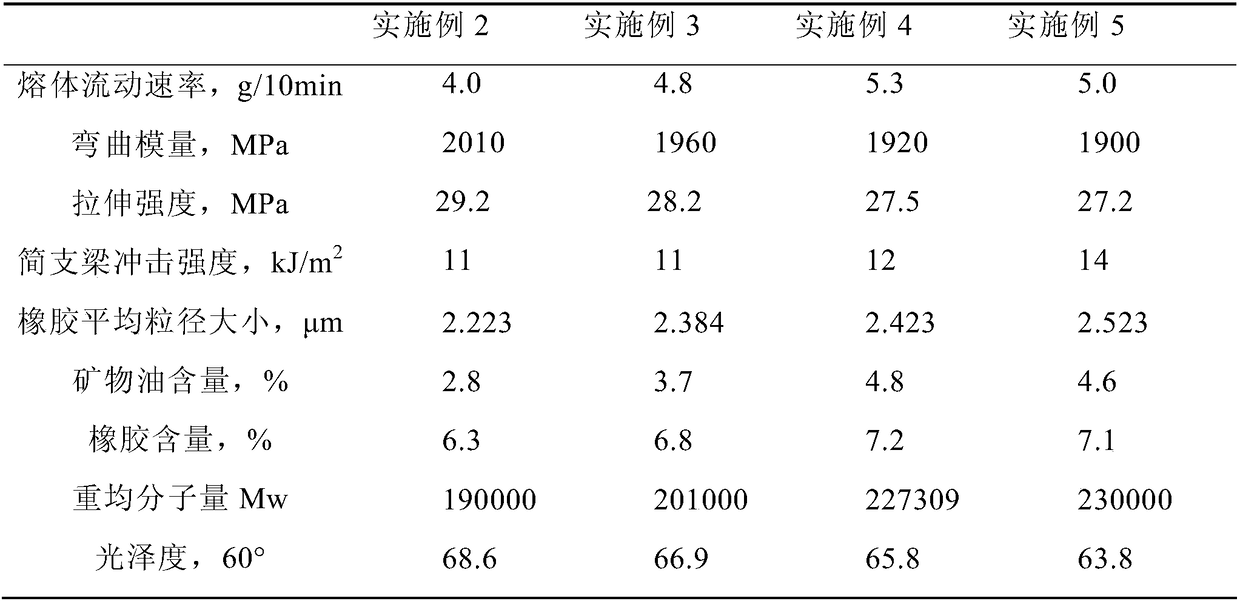

Embodiment 2

[0047] In this embodiment, the equipment in Embodiment 1 is used to prepare raw materials for yogurt cup sheets.

[0048] 1. Prepare materials

[0049] 4.5 parts by weight of polybutadiene rubber: a mixture of the first low-cis polybutadiene rubber and the second low-cis polybutadiene rubber in a mass ratio of 1:1;

[0050] Wherein, the first low-cis polybutadiene rubber is a star structure, Mooney viscosity (50ML (1+4) 100 ℃) is 50, and at 25 ℃, the viscosity in 5wt% styrene is 34.8mPa· s;

[0051] The second low cis-polybutadiene rubber has a linear structure, the Mooney viscosity (50ML(1+4)100°C) is 51, and at 25°C, the viscosity of 5wt% styrene is 165mPa·s;

[0052] β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate) 0.05 parts by weight;

[0053] 0.5 parts by weight of zinc stearate;

[0054] 12 parts by weight of ethylbenzene;

[0055] 3 parts by weight of mineral oil;

[0056] 79.95 parts by weight of styrene.

[0057] 2. Formation of the first mixture ...

Embodiment 3

[0070] In this embodiment, the equipment in Embodiment 1 is used to prepare raw materials for yogurt cup sheets.

[0071] 1. Prepare materials

[0072] 5 parts by weight of polybutadiene rubber: a mixture of the first low-cis polybutadiene rubber and the second low-cis polybutadiene rubber in a mass ratio of 1:1;

[0073] Wherein, the first low-cis polybutadiene rubber is a star structure, Mooney viscosity (50ML (1+4) 100 ℃) is 51, and at 25 ℃, the viscosity in 5wt% styrene is 35.8mPa· s;

[0074] The second low cis-polybutadiene rubber is a linear structure, the Mooney viscosity (50ML(1+4)100°C) is 52, and at 25°C, the viscosity of 5wt% styrene is 168mPa·s;

[0075] β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate) 0.08 parts by weight;

[0076] 0.7 parts by weight of zinc stearate;

[0077] 17 parts by weight of ethylbenzene;

[0078] 4 parts by weight of mineral oil;

[0079] 73.22 parts by weight of styrene.

[0080] 2. Formation of the first mixture

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com