Integrated large-angle rolling and posture adjusting rack car

A large-angle, rolling technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve problems such as back and forth rework, multiple hoisting, and low safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

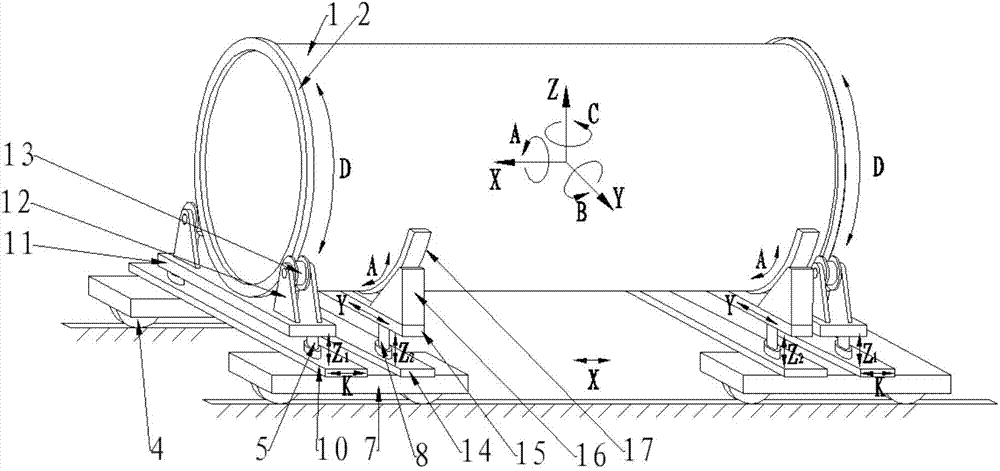

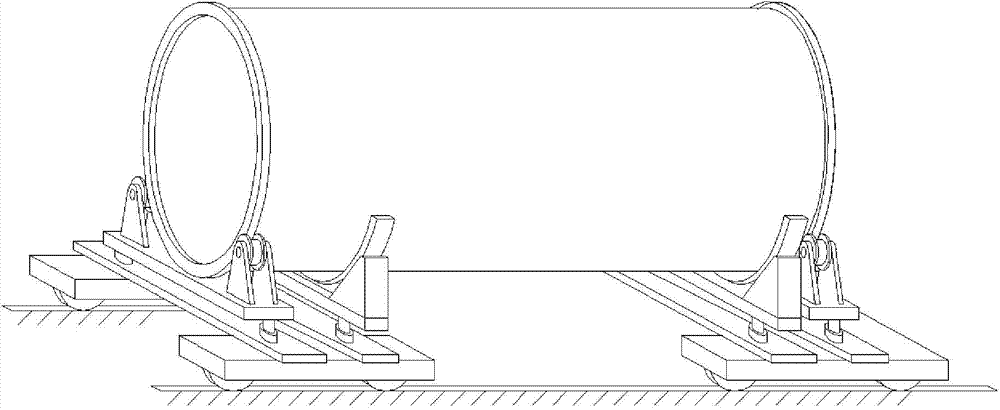

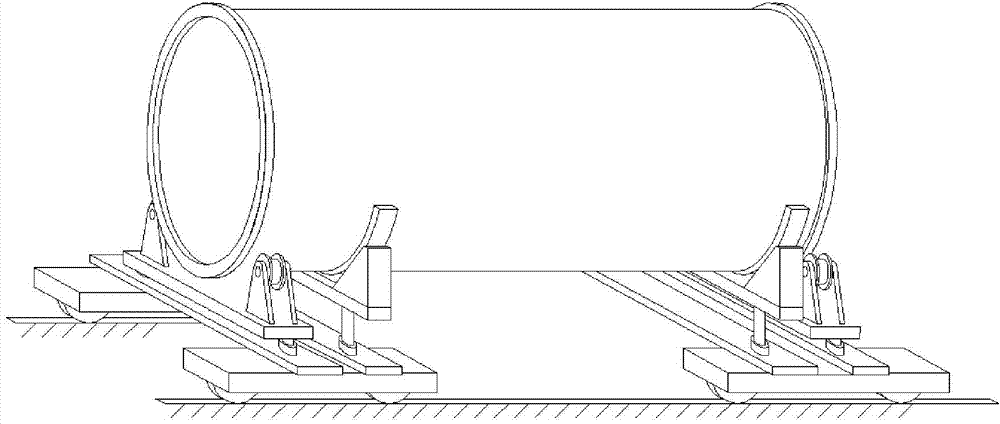

[0028] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0029] A large-angle rolling and attitude-adjusting integrated frame vehicle, comprising two guide rails arranged in parallel, and two mobile frames 7 horizontally mounted on the guide rails, and the mobile frames 7 can be moved along the The guide rail moves, and the plane formed by the moving directions of the two mobile frames 7 is a horizontal plane, and each of the mobile frames 7 includes a rolling bracket and a docking bracket, and the docking bracket is located between the two The side of the mobile frame 7 close to each other, the rolling bracket is located on the side of the two mobile frames 7 away from each other, and also includes a detachable rolling ring 2, the detachable rolling The ring 2 can roll on the rolling bracket, and the detachable rolling ring 2 is formed by connecting a plurality of equally divided rings, and each of the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com