Plug type wiring terminal assembly

A technology of terminal blocks and plug parts, which is applied in the field of plug-type terminal assemblies, can solve the problems of reducing wiring efficiency, unsatisfactory wiring effects, and reducing labor intensity, etc., and achieves high construction efficiency, simple and convenient wiring, and easy wiring. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

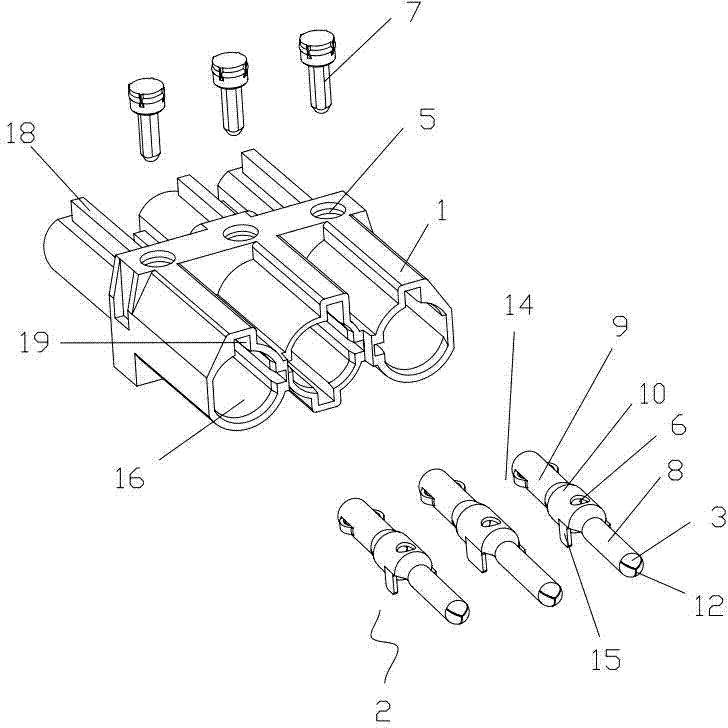

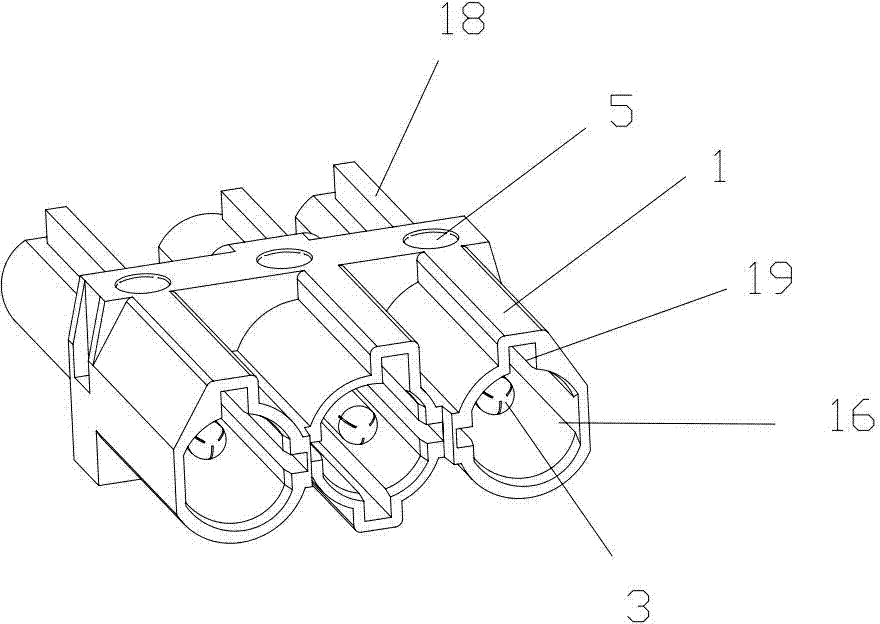

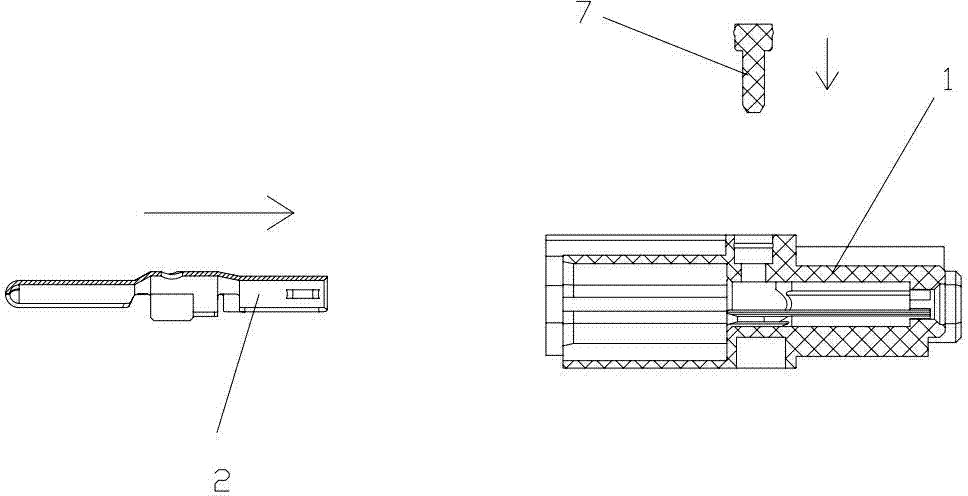

[0029] A plug type terminal assembly described in Embodiment 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10As shown, it includes an insulating housing 1 and a conductive metal plug 2 disposed in the insulating housing. One end of the conductive metal plug is provided with a plug head 3, and the other end is provided with a plug opening 4; the top of the insulating housing is provided with a housing Socket 5, the top of the conductive metal plug is provided with a first conductive metal socket 6 corresponding to the housing socket, and through the housing socket and the first conductive metal socket in turn is provided with an insulation that can make the conductive metal plug fixed in the insulating housing. Plug-in 7; the two ends of the insulating shell are respectively provided with shell wiring ports that allow the conductive metal plug to be inserted into the insulating shell. The c...

Embodiment 2

[0035] Present embodiment 2 changes on the basis of embodiment 1, and its specific structure is as follows:

[0036] Such as Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, the plug head 3 is inserted into the insulating casing 1 from the socket 16 of the female casing, and the installation and insertion method of the conductive metal plug is reversed and inserted into the insulating casing. When the conductive metal plug is installed in the insulating housing, the reverse installation can adapt to different fields and different wiring requirements. In addition, the metal sheet is horizontally arranged on the hollow connector, that is, it is horizontally fixed in the cavity of the insulating housing, and the function of the metal sheet is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com