Cyclic polyester cbt/wood plastic composite

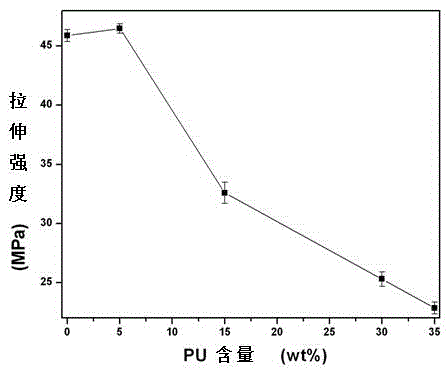

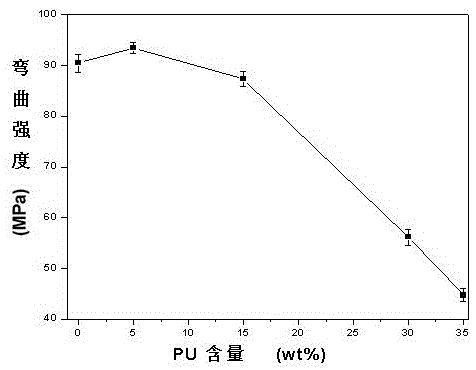

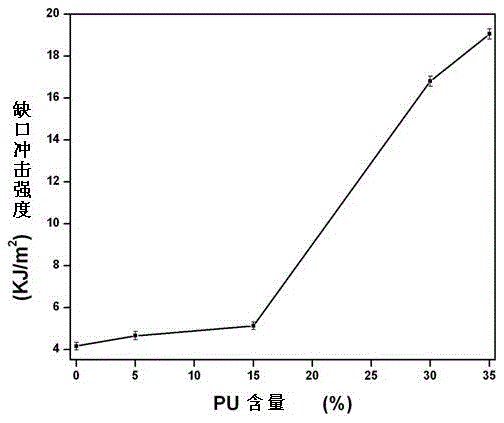

A wood-plastic composite material and cyclic polyester technology, which is applied in the field of wood-plastic composite materials, can solve the problems of low tensile strength, low bending strength, use, and processing temperature that cannot be applied, and achieve the effect of good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Cyclic polyester CBT / wood-plastic composite material, the weight ratio of the raw materials of the material is: cyclic polyester CBT 7.0kg, polyurethane PU (polyethylene) 0kg, bamboo powder 3.0kg, the bamboo powder passed through 100 o C dried for 24 hours, particle size 100 mesh.

Embodiment 2

[0015] Cyclic polyester CBT / wood-plastic composite material, the weight ratio of the raw materials of the material is: cyclic polyester CBT6.5kg, polyurethane PU (polyethylene) 0.5kg, bamboo powder 3.0kg, the bamboo powder passed through 100 o C dried for 24 hours, particle size 100 mesh.

Embodiment 3

[0017] Cyclic polyester CBT / wood-plastic composite material, the weight ratio of the raw materials of the material is: cyclic polyester CBT 5.5kg, polyurethane PU (polyethylene or polypropylene) 1.5kg, bamboo powder 3.0kg, the bamboo powder after 100 o C dried for 24 hours, particle size 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com