A glove box small transition cabin door and a glove box transition cabin

A transition cabin and glove box technology, applied in the field of glove boxes, can solve the problems of difficult door closing, inconvenient operation, short service life of sealing parts, etc., and achieve the effects of avoiding inconsistent deformation, simple and reasonable structure, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

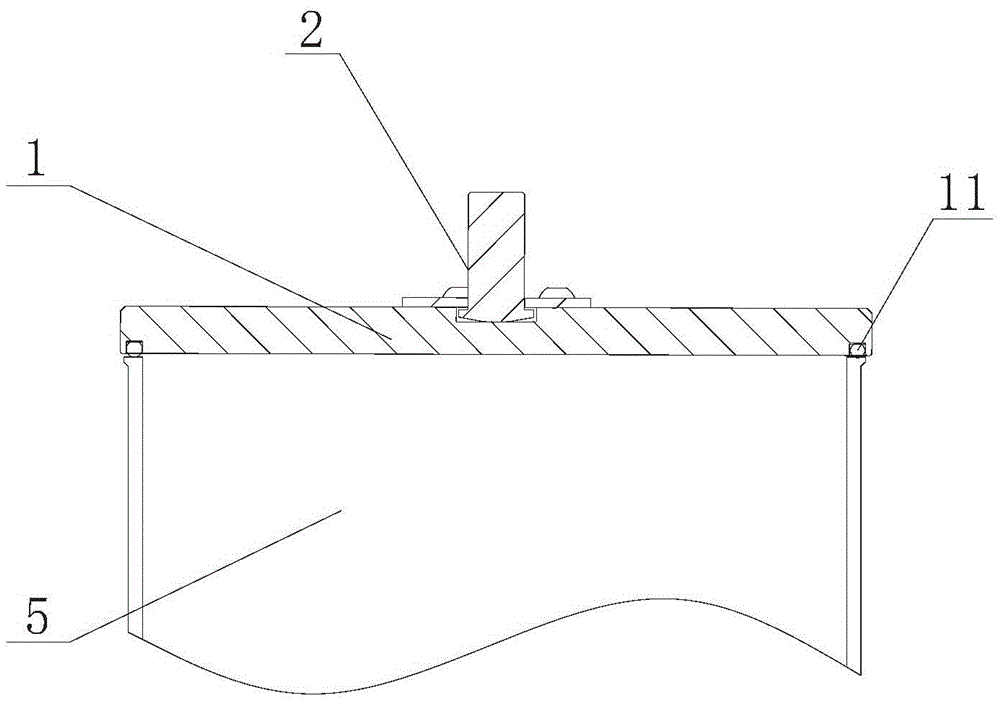

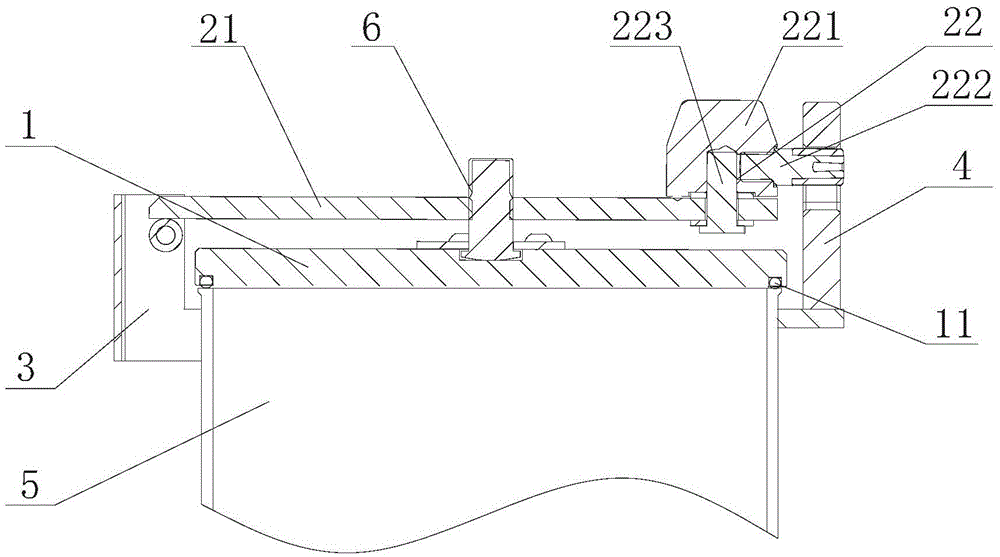

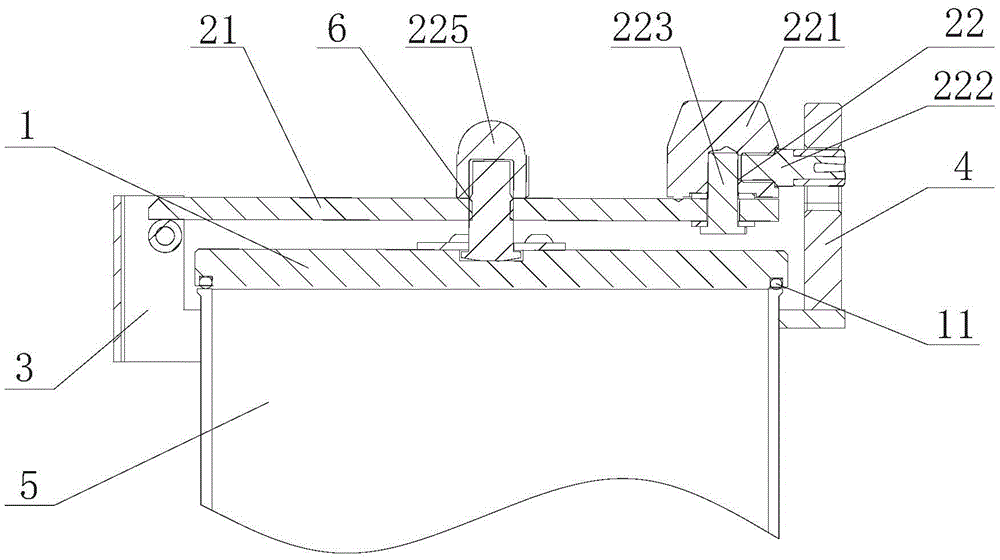

[0029] A hatch of a small transition compartment of a glove box, which is used to close or open the compartment of a small transition compartment of a glove box, and in some embodiments, it includes:

[0030] The cabin door is arranged on the cabin door opening and closing device;

[0031] A sealing component, the sealing component is arranged on the frame of the cabin opening of the small transition cabin of the glove box and corresponds to the inner side of the cabin door, and is used to seal the cabin body of the small transition cabin of the glove box;

[0032] The hatch door opening and closing device is installed on the cabin body of the small transition compartment of the glove box, and is used to apply a free force to the center of the hatch door when closing the hatch door and distribute it evenly on the hatch door so that the hatch door can be freely attached to the glove box The hatch of the small transition cabin is closed to close the hatch, and when the hatch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com