A kind of alloying element reinforced high-silicon-aluminum composite material and preparation method thereof

A composite material and alloying element technology, applied in the field of alloying element reinforced high-silicon-aluminum composite material and its preparation, can solve the problems of poor comprehensive performance of composite materials, difficult processing and welding, and difficulty in meeting use requirements, and achieves good consistency. , Excellent comprehensive performance, the effect of inhibiting the growth of silicon phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

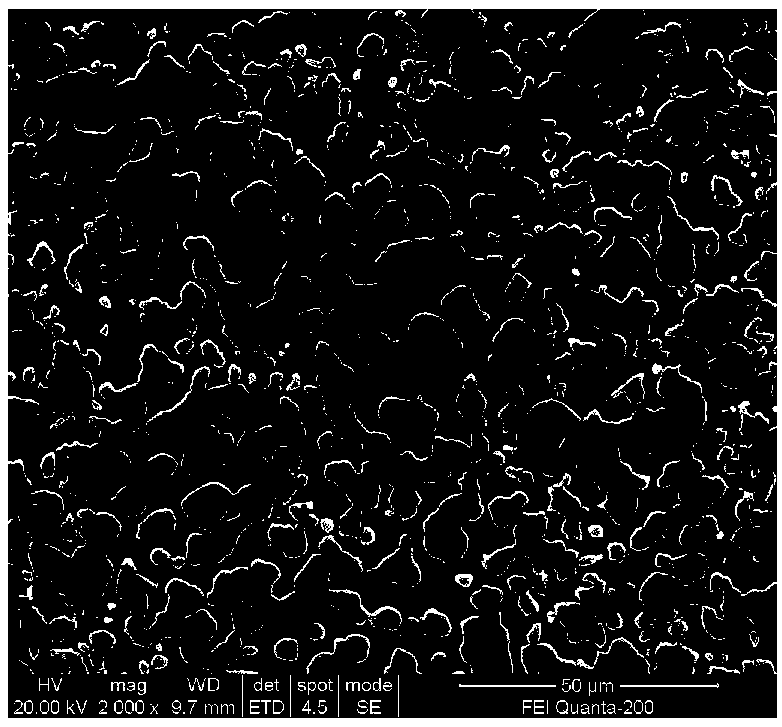

[0042] Preparation of Al-50Si-2Cu composite materials.

[0043]1) The raw materials are single crystal silicon, high-purity aluminum (99.998-99.999% Al), aluminum-copper master alloy (60% Cu), and the ingredients of each alloy element are as follows: silicon: 50%, copper: 2%, and the balance is aluminum.

[0044] 2) Tundish preheating, the preheating temperature is about 960°C.

[0045] 3) Melting: Put the high-purity aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 820°C. After the aluminum ingot is completely melted, raise the temperature to 1200°C. At the same time, add monocrystalline silicon in batches, and cool down to 800°C after the monocrystalline silicon is completely melted. , add aluminum-copper master alloy, stir thoroughly for 5 minutes, cover slagging with 30% NaCl+47% KCl+23% cryolite, and degas with hexachlorohexane.

[0046] 4) Atomization and deposition: heat the molten alloy to 850°C, keep it warm for 5 minutes, p...

Embodiment 2

[0058] Al-50Si-1Mg composites were prepared.

[0059] 1) The raw materials are single crystal silicon, high-purity aluminum (99.998-99.999% Al), aluminum-magnesium master alloy (67% Mg), and the ingredients of each alloy element are as follows: silicon: 50%, magnesium: 1%, and the balance is aluminum.

[0060] 2) Tundish preheating, the preheating temperature is about 960°C.

[0061] 3) Melting: Put the high-purity aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 820°C. After the aluminum ingot is completely melted, raise the temperature to 1200°C. At the same time, add monocrystalline silicon in batches, and cool down to 780°C when the monocrystalline silicon is completely melted. , add aluminum-magnesium master alloy, fully stir for 5 minutes, cover slagging with 30% NaCl+47% KCl+23% cryolite, and degas with hexachlorohexane.

[0062] 4) Atomization and deposition: raise the temperature of the molten alloy to 845°C, keep it warm fo...

Embodiment 3

[0066] Al-50Si-1Cu-0.5Mg composites were prepared.

[0067] 1) The raw materials are single crystal silicon, high-purity aluminum (99.998-99.999% Al), aluminum-copper master alloy (60% Cu), aluminum-magnesium master alloy (67% Mg), and the ingredients of each alloy element are as follows: Silicon: 50 %, copper: 1%, magnesium: 0.5%, and the balance is aluminum.

[0068] 2) Tundish preheating, the preheating temperature is about 960°C.

[0069] 3) Melting: Put the high-purity aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 820°C. After the aluminum ingot is completely melted, raise the temperature to 1200°C. At the same time, add monocrystalline silicon in batches, and cool down to 800°C after the monocrystalline silicon is completely melted. , add aluminum-copper master alloy, stir for 5 minutes and cool down to 780°C, add aluminum-magnesium master alloy, stir for another 5 minutes, cover with 30% NaCl+47% KCl+23% cryolite to form sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com