Square hole lamp

A technology of square holes and light panels, applied in lighting devices, cooling/heating devices of lighting devices, electric light sources, etc., can solve the problems of easily damaged structure, troublesome correction and adjustment of concentration, narrow projection range, etc. Wide range, flexible rotation, firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

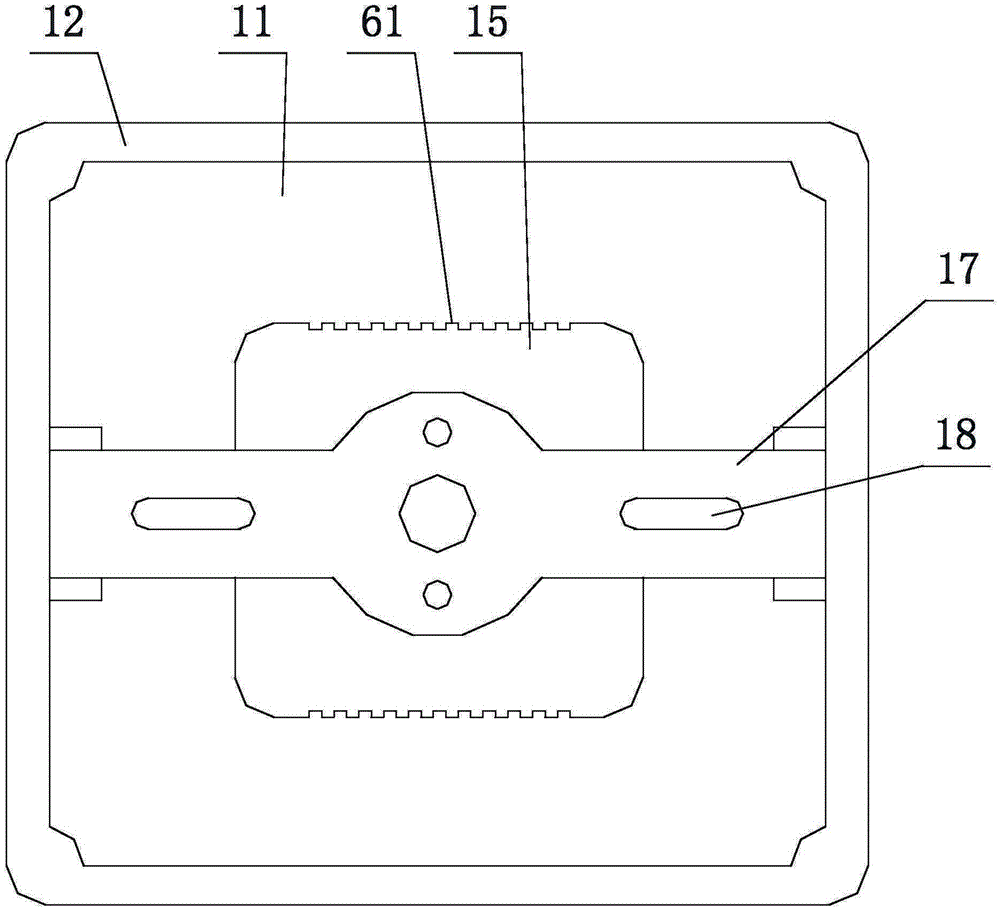

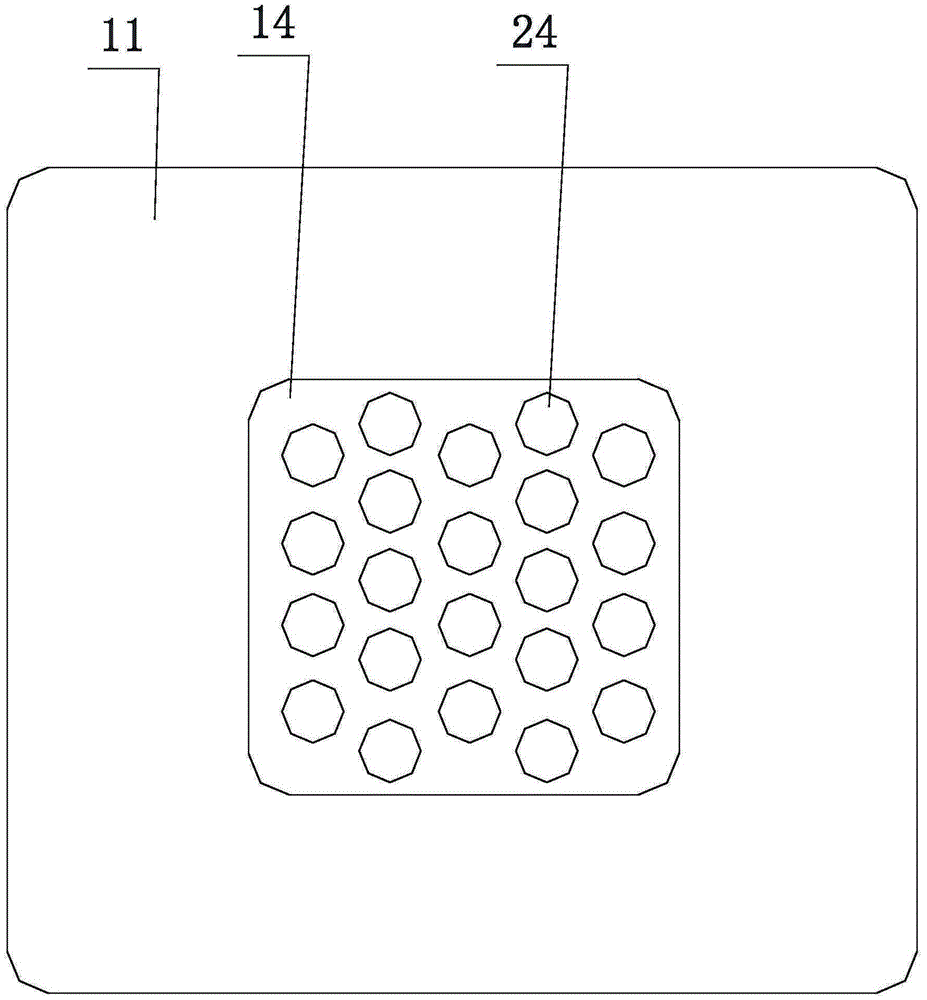

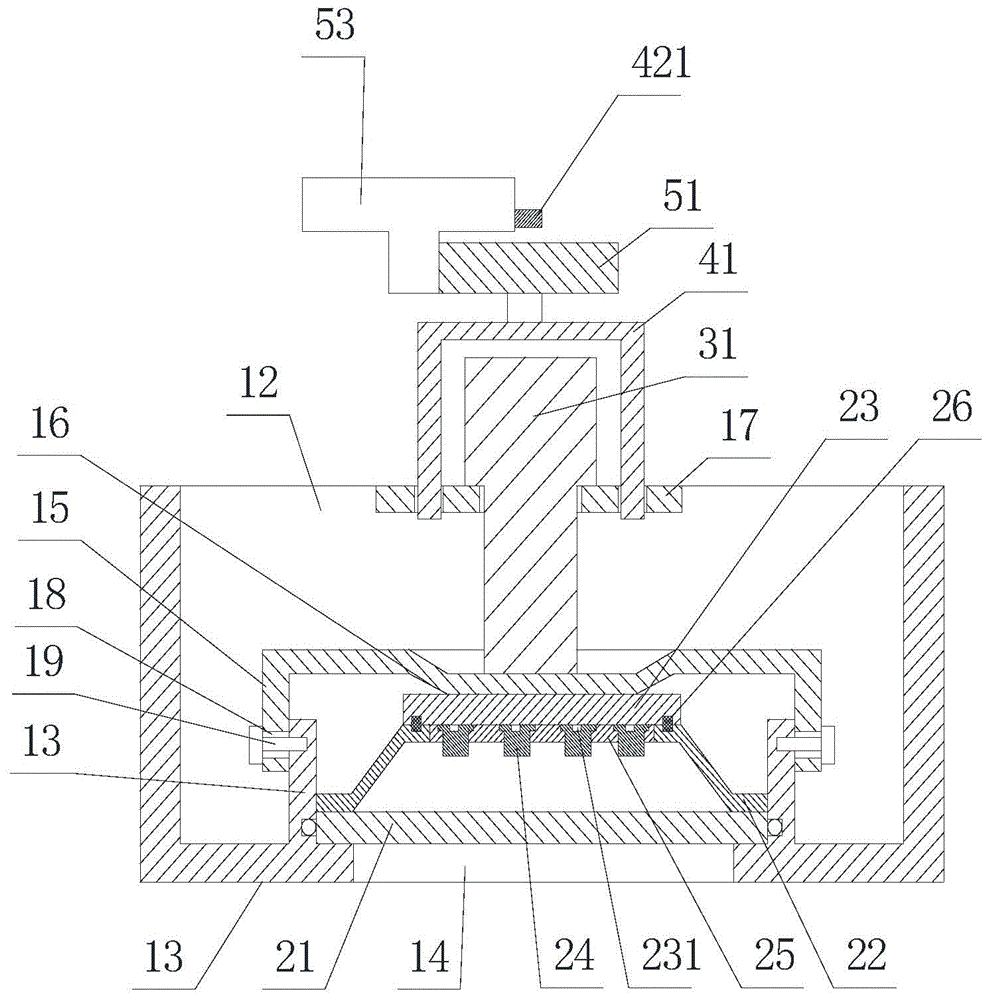

[0015] Such as Figures 1 to 4 As shown, the square hole lamp includes a lamp housing composed of a bottom plate 11, an outer ring 12 arranged on the top surface of the bottom plate 11, and an inner ring 13 arranged on the top surface of the bottom plate 11. The inner ring 13 is located in the outer ring 12, and the inner ring 13 The height of the inner ring 13 is lower than that of the outer ring 12. The middle part of the bottom plate 11 has a light outlet 14. The inner ring 13 is provided with a panel 21, a reflector 22 and a light board 23 in sequence from bottom to top. The top of the inner ring 13 is covered with a cover plate 15. , the inner ring 13 is socketed with the cover plate 15, and the two are slidably fitted. An anti-separation structure is provided between the inner ring 13 and the cover plate 15 to prevent the two from detaching. The inner top surface of the cover plate 15 has a 23 The protrusion 16 on the top surface, the side of the lamp board 23 facing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com