Patents

Literature

49 results about "Chinese magic mirror" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Chinese magic mirror is an ancient art that can be traced back to the Chinese Han dynasty (206 BC – 24 AD). The mirrors were made out of solid bronze. The front is a shiny polished surface and could be used as a mirror, while the back has a design cast in the bronze. When bright sunlight or other bright light reflects onto the mirror, the mirror seems to become transparent. If that light is reflected from the mirror towards a wall, the pattern on the back of the mirror is then projected onto the wall.

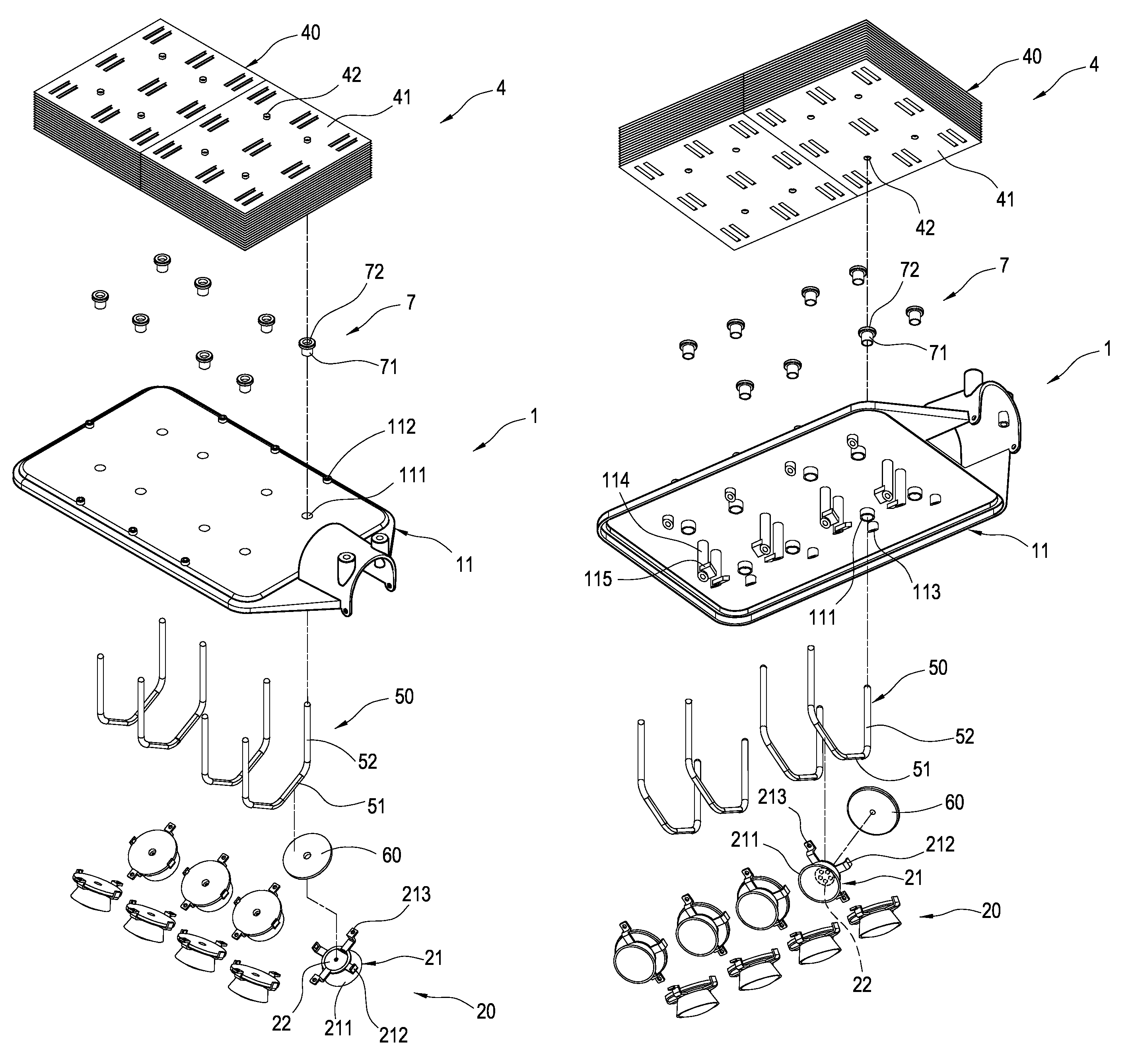

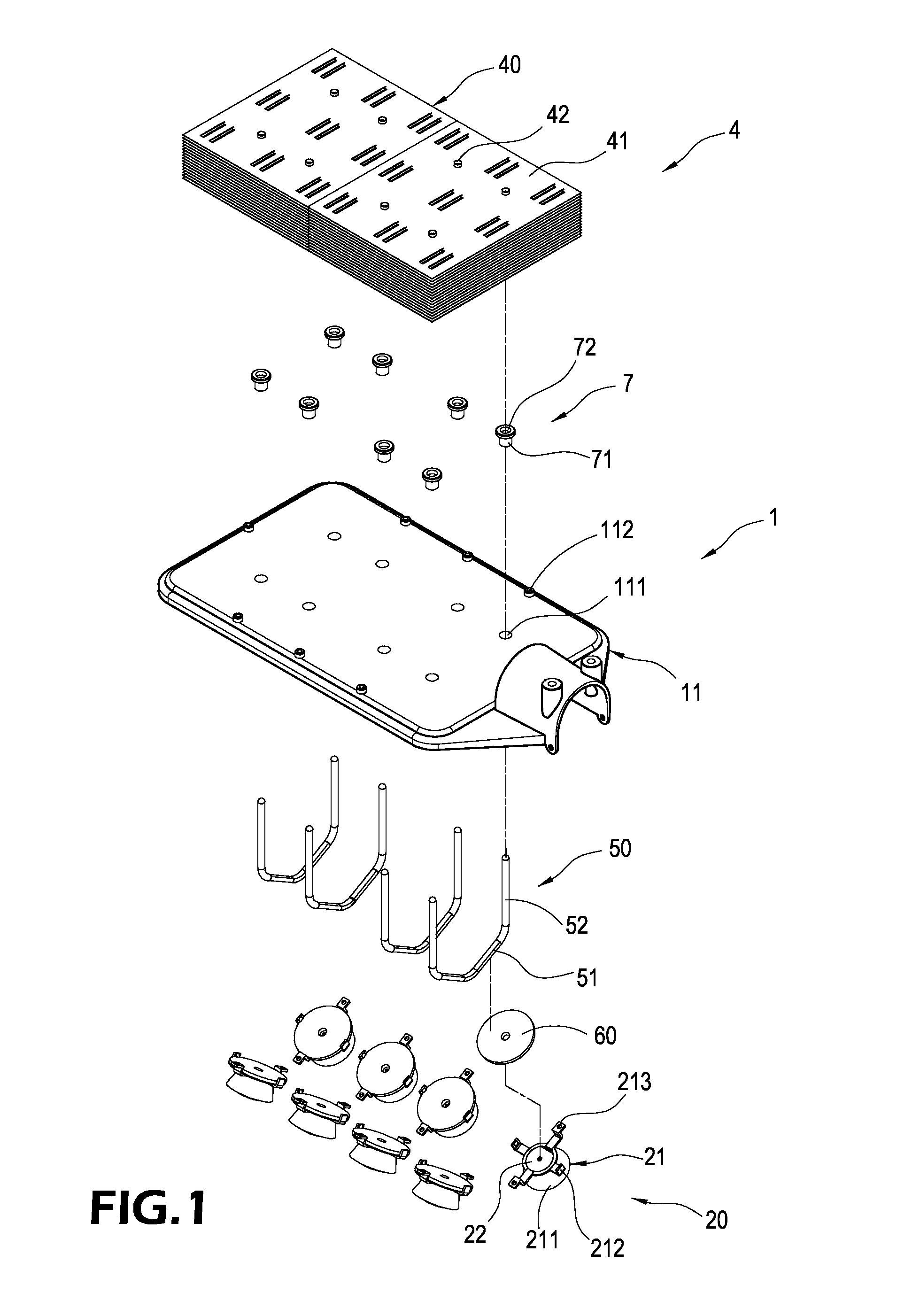

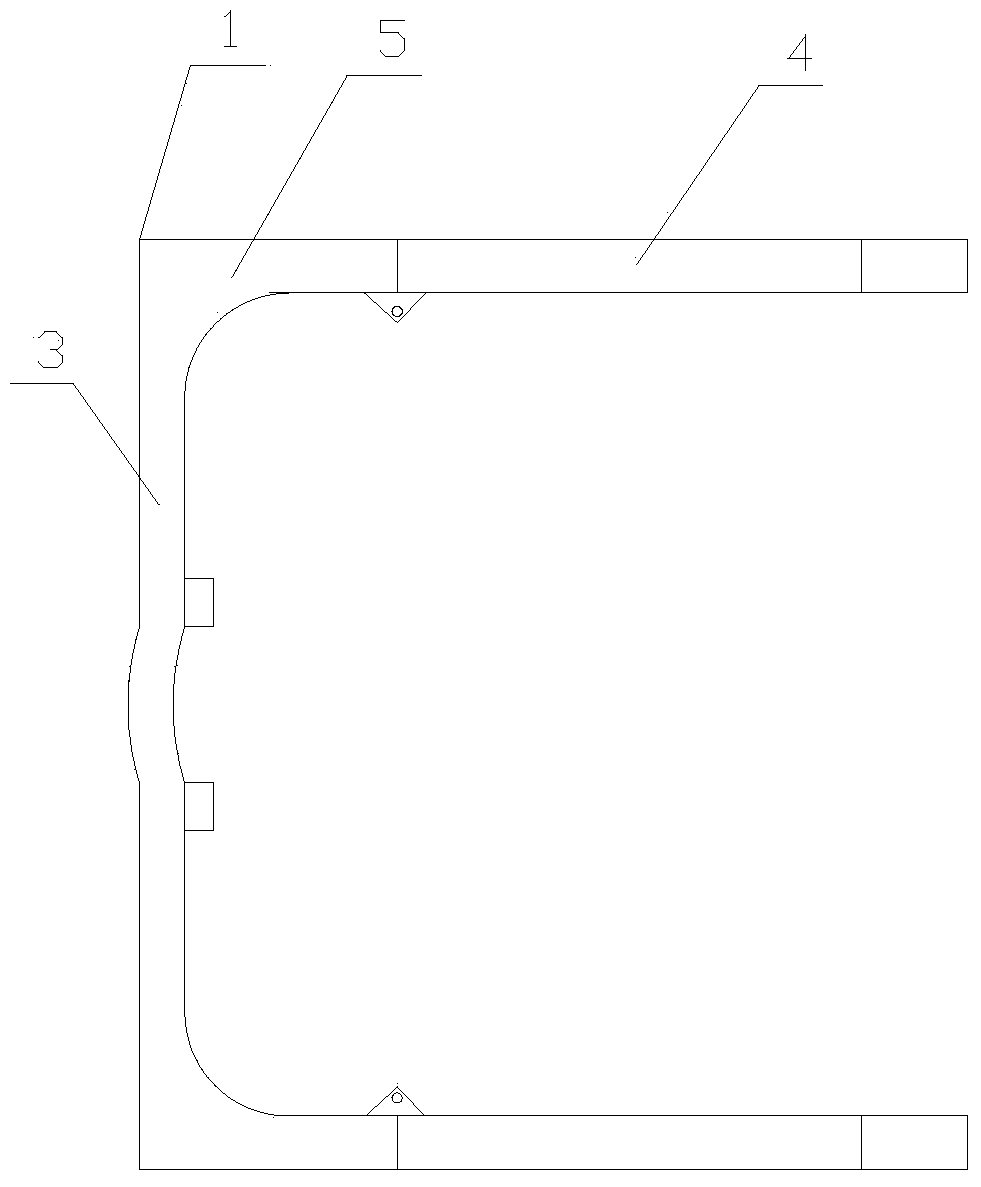

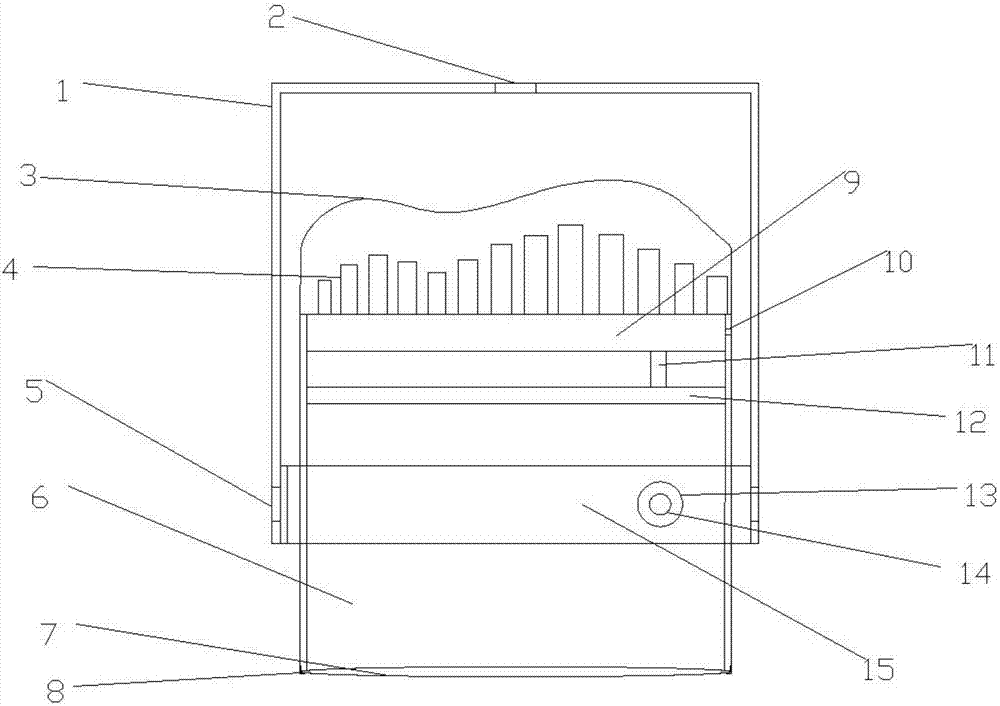

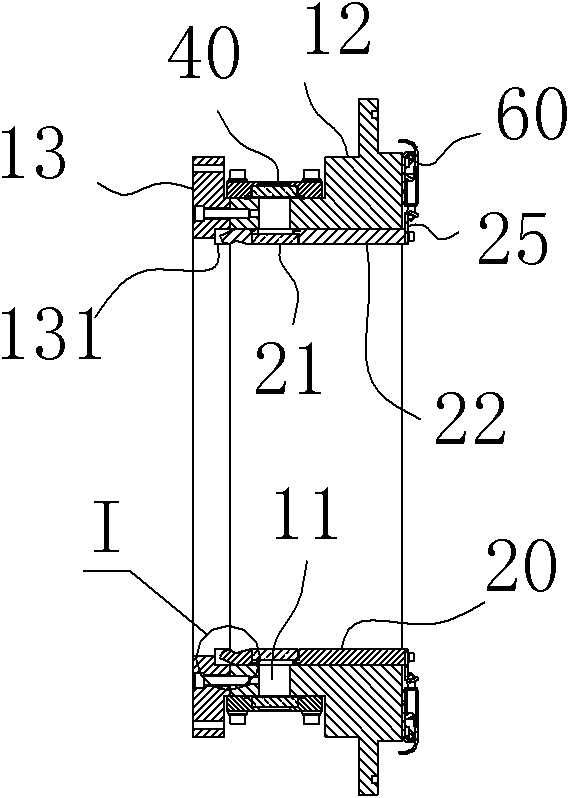

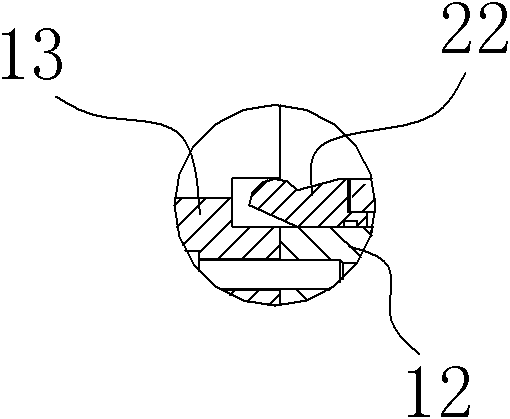

Assembling structure for LED road lamp and heat dissipating module

InactiveUS20080043479A1Produce heatFast heat conductionMechanical apparatusPoint-like light sourceHeat conductingEngineering

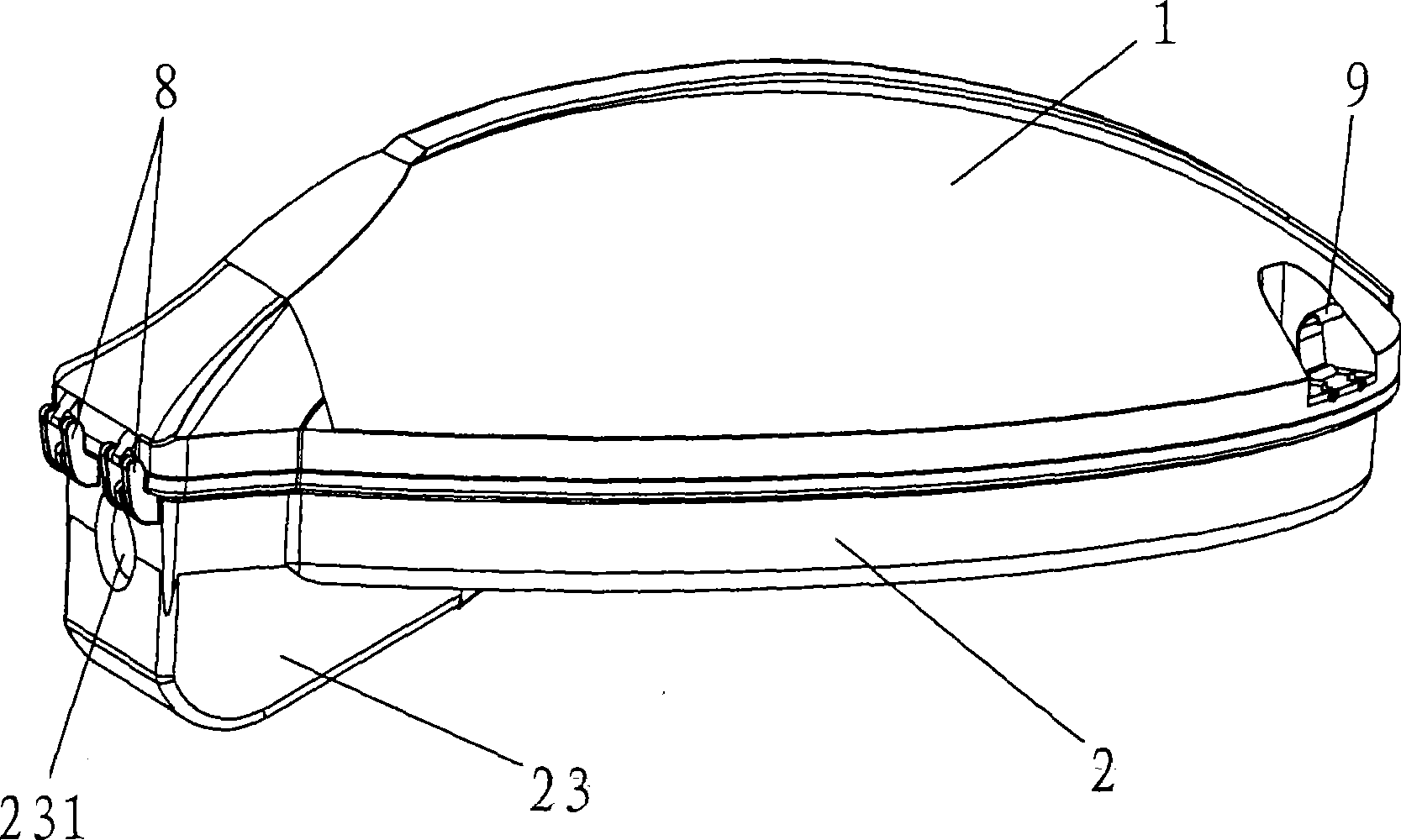

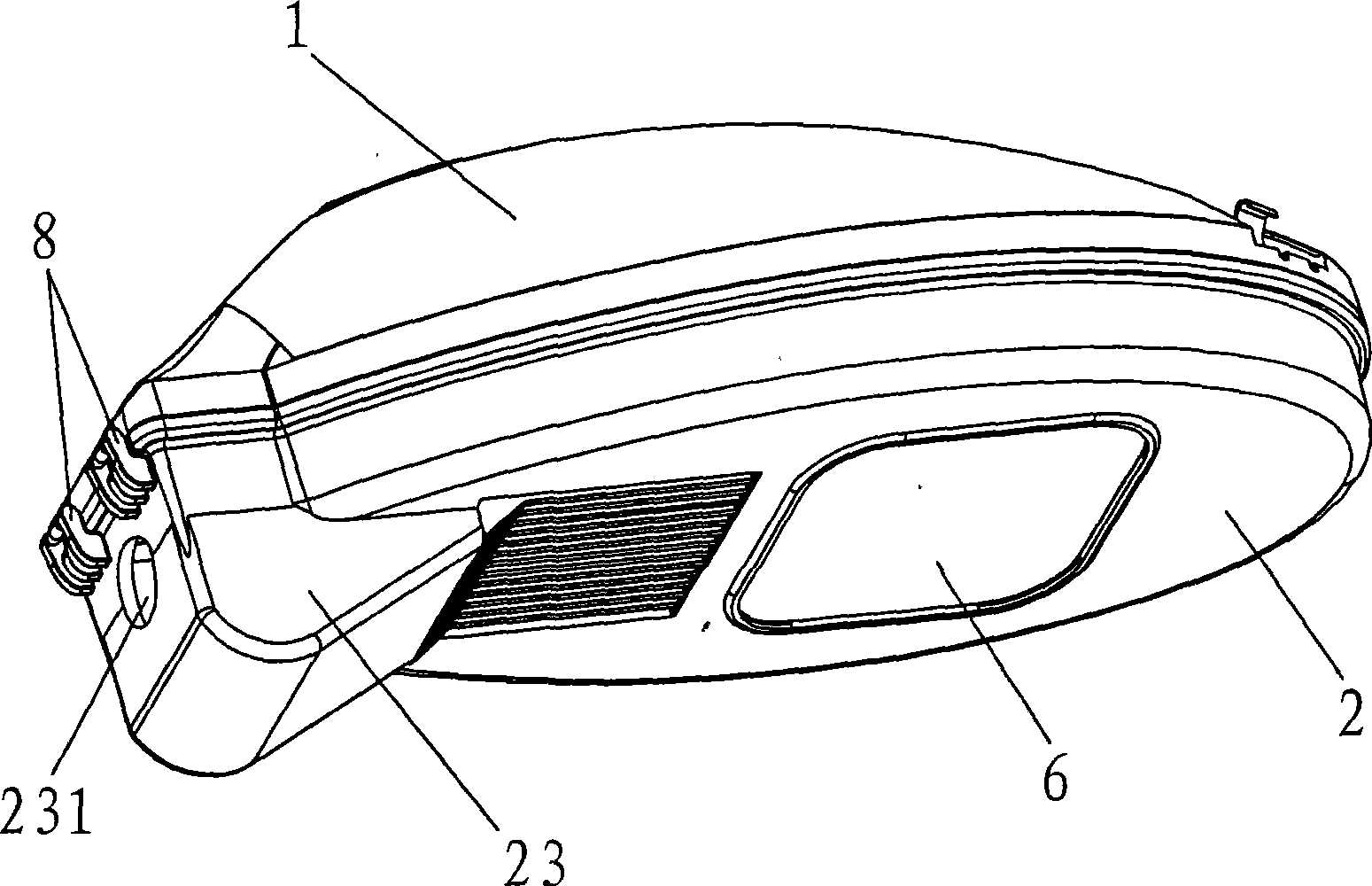

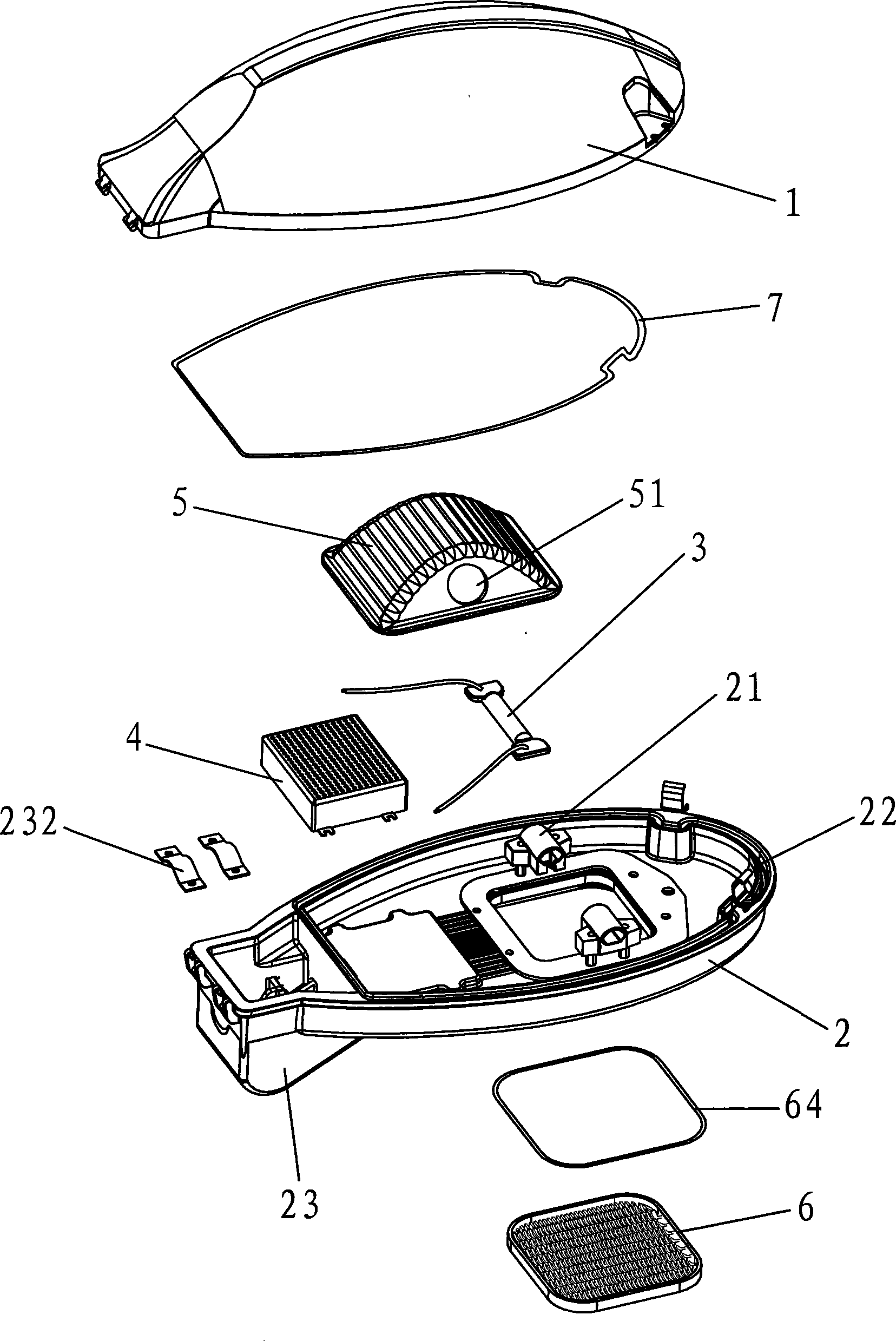

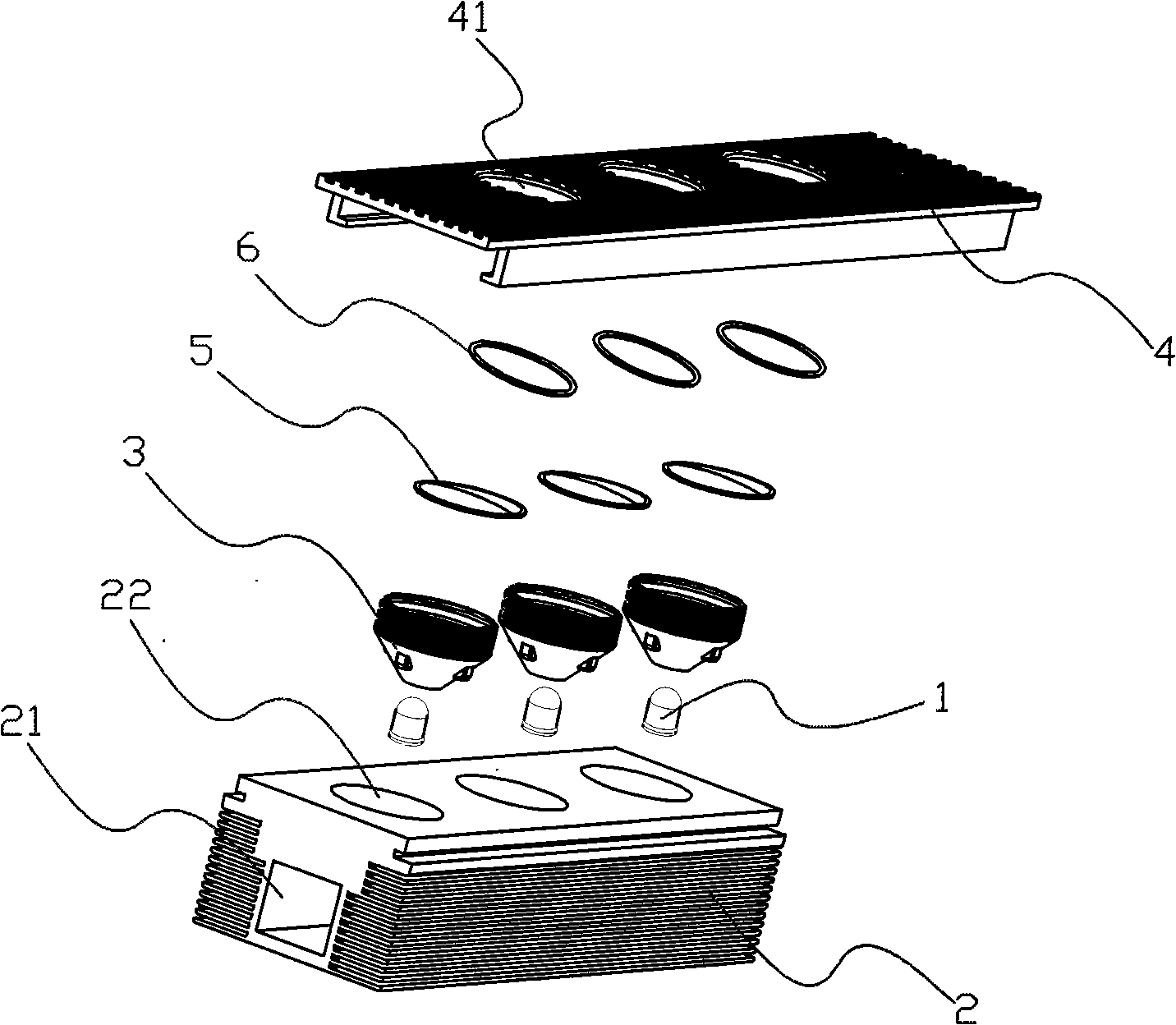

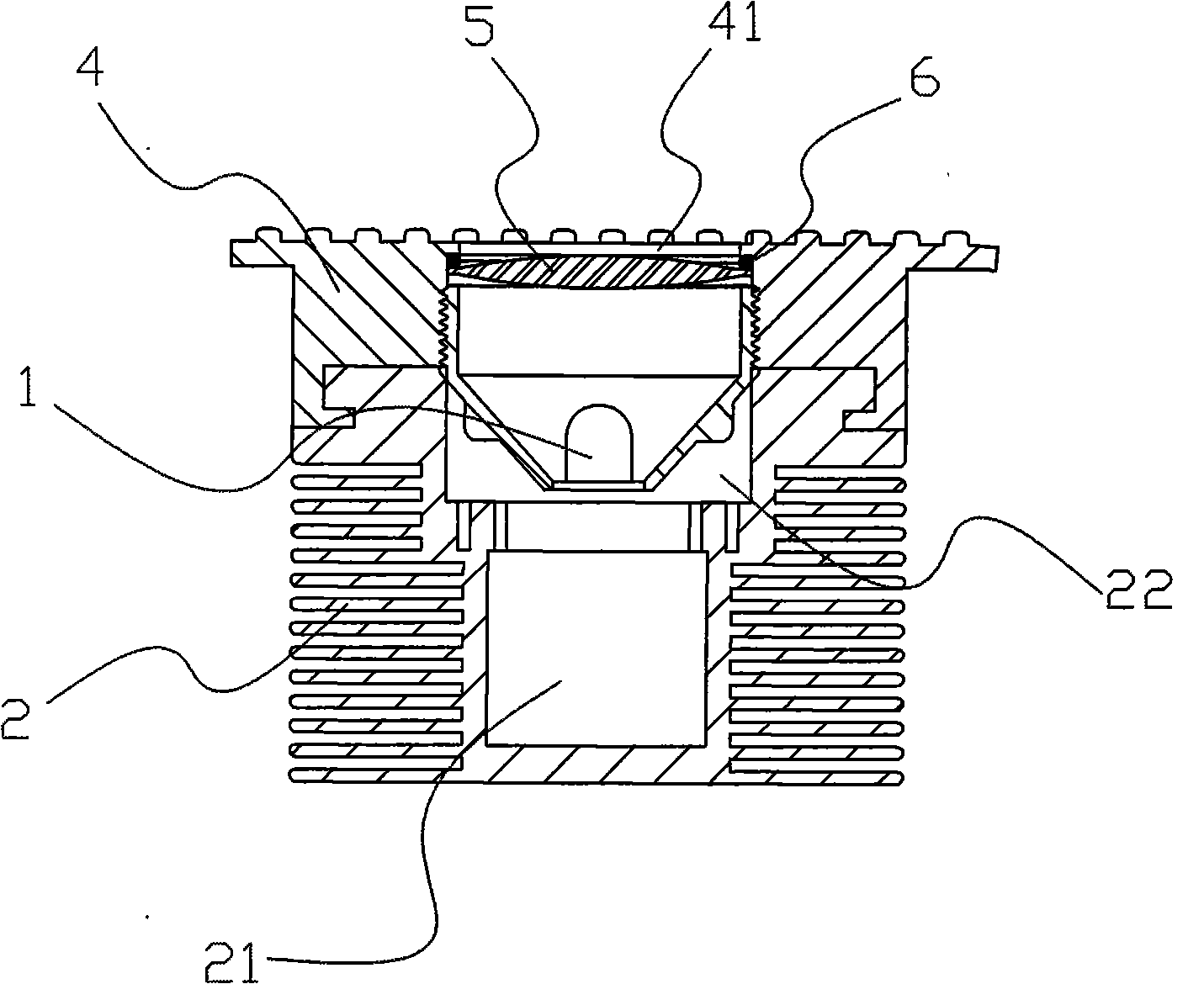

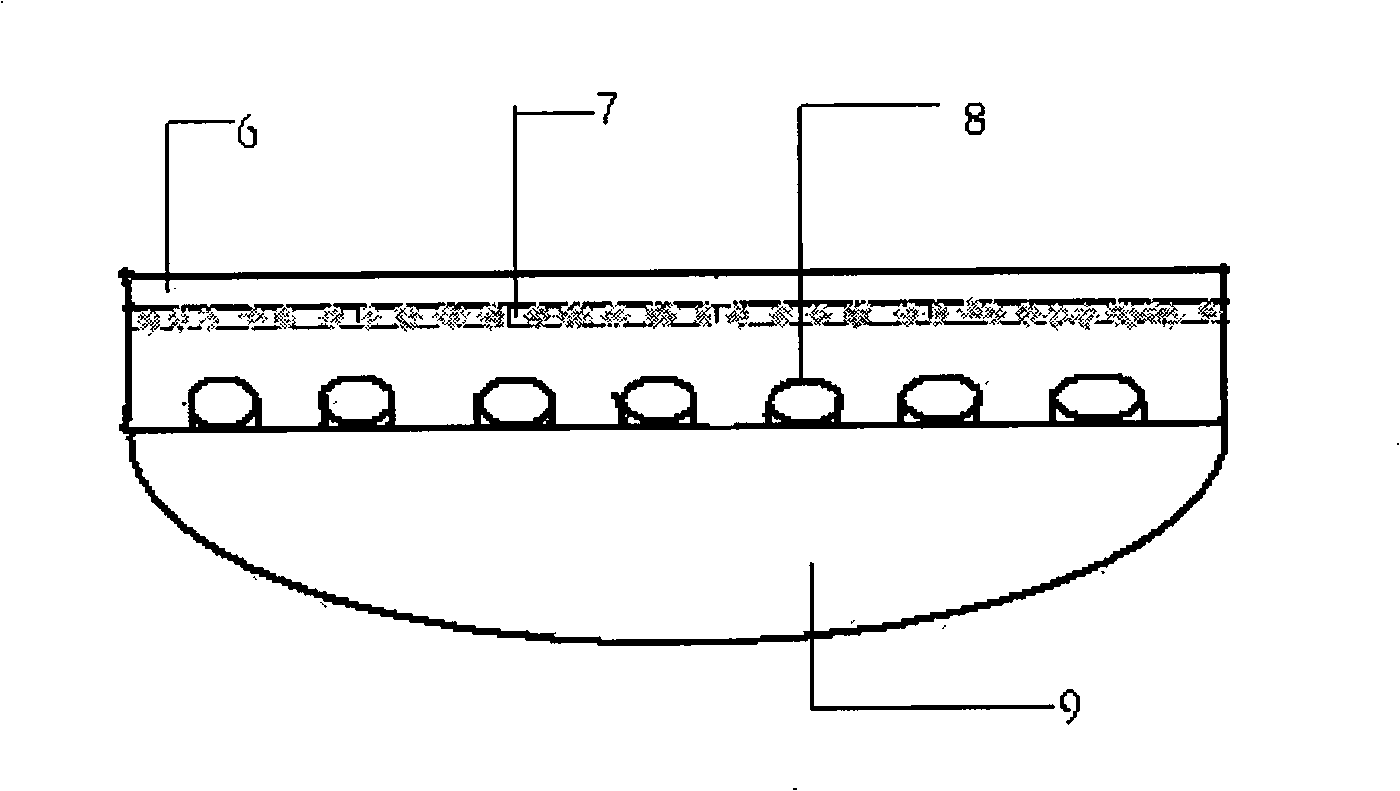

In an assembling structure for LED road lamp and heat dissipating module, the LED road lamp includes a partition board, an upper casing, a light transmitting lens and an LED lamp set. The upper casing and the light transmitting lens are set separately on upper and lower sides of the partition board. Each LED lamp set is contained in a space enclosed by the partition board and the light transmitting lens. The partition board has a plurality of through holes, and the LED lamp set includes a frame body and an LED module. The heat dissipating module includes a heat dissipating body, a heat pipe and an isothermal board. The heat dissipating body is set in a space enclosed by the partition board and the upper casing, and the heat pipe has a heat discharging end passing through and connecting the partition board and the heat dissipating body and a heat receiving end forming the bottom of the partition board. The isothermal board is fixed onto a frame body of the LED lamp and has two planes separately attached onto the heat receiving end and the LED module, so as to significantly enhance the overall heat conducting and dissipating performance, drive an LED to emit light at a lower temperature, and extend the life expectancy of the LED.

Owner:PYROSWIFT HOLDING CO LIMITED

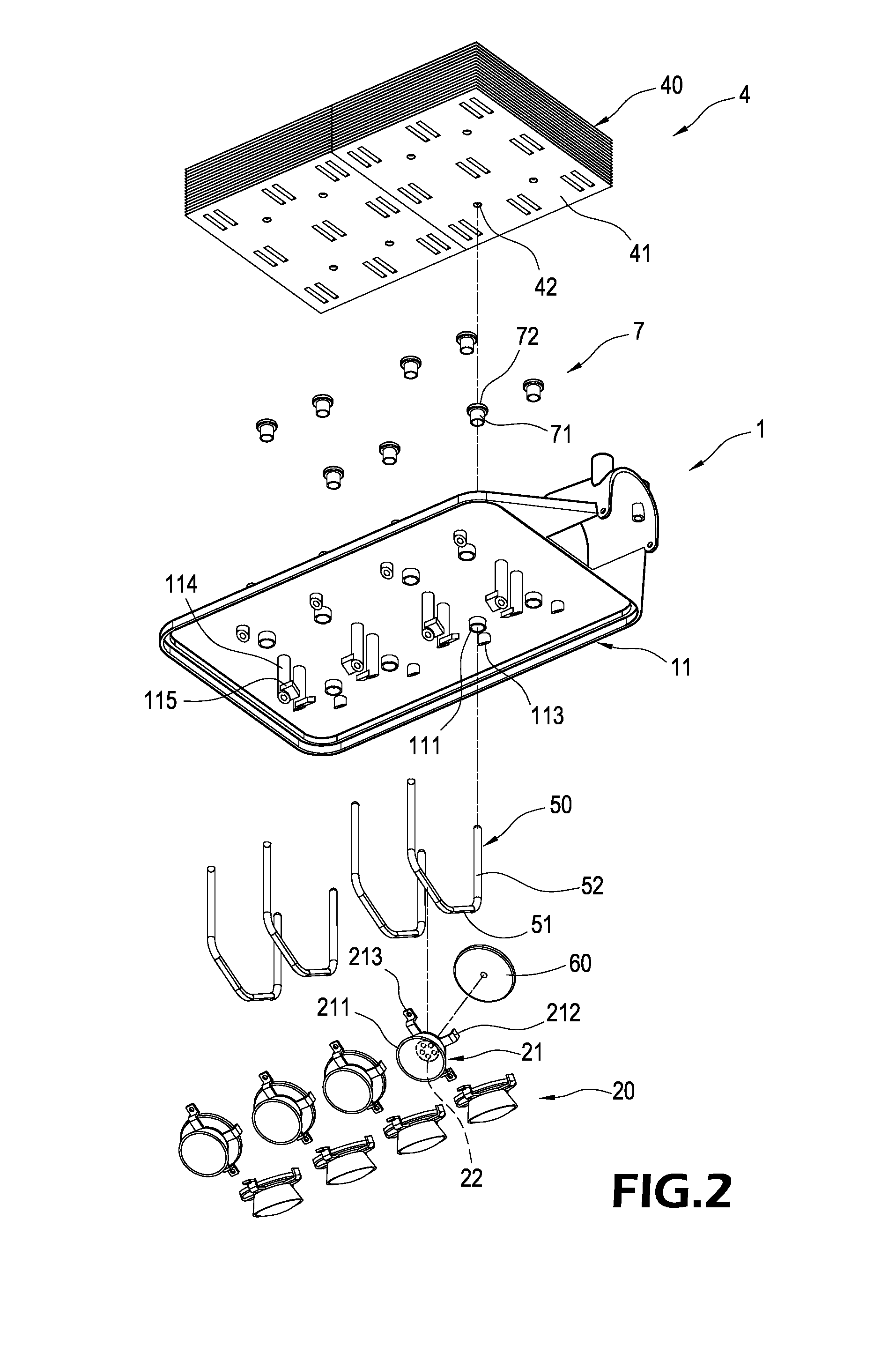

LED Lamp Illumination Projecting Structure

InactiveUS20080019129A1Good directionReduce brightness unevennessMechanical apparatusPoint-like light sourceEngineeringLED lamp

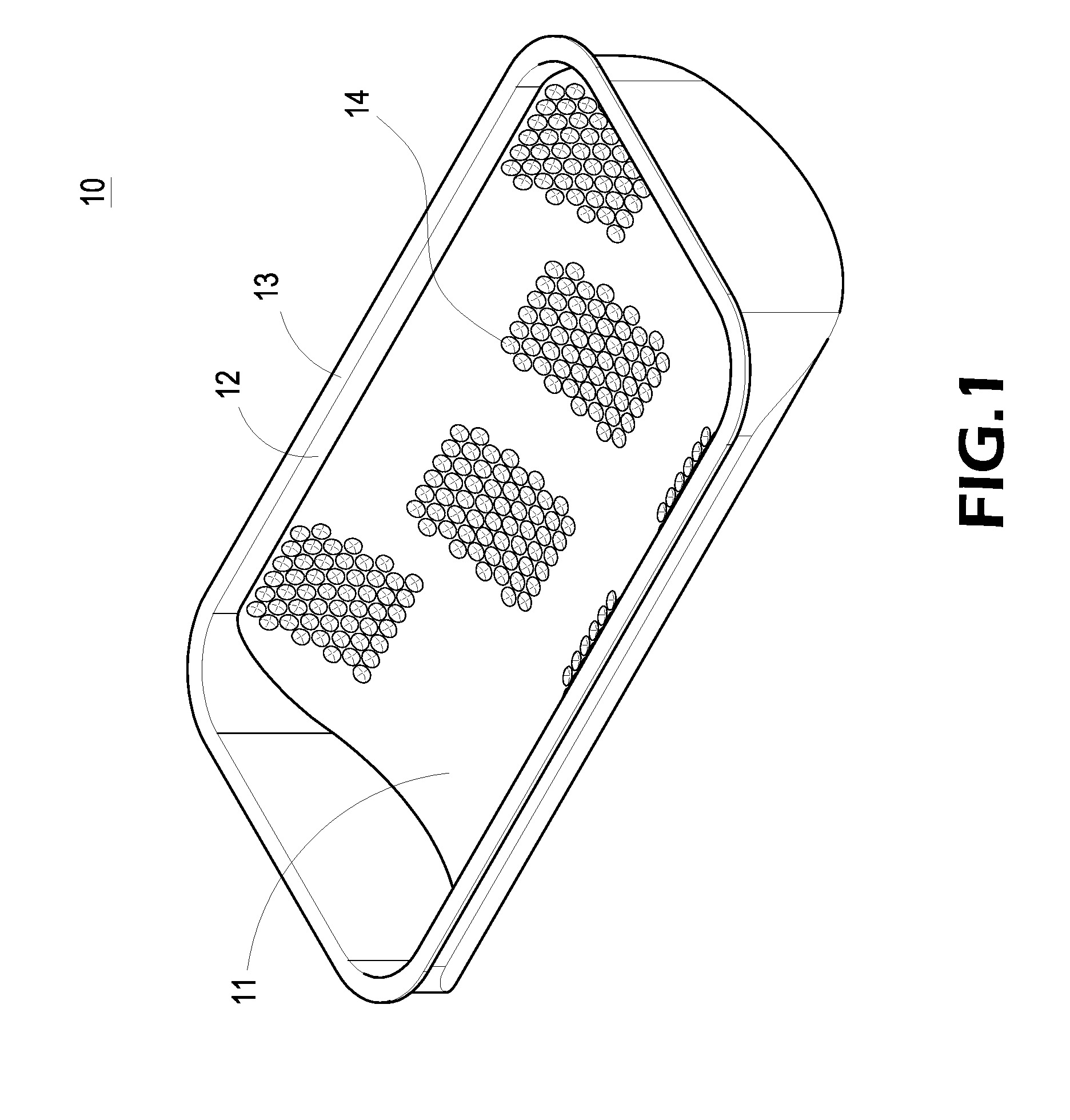

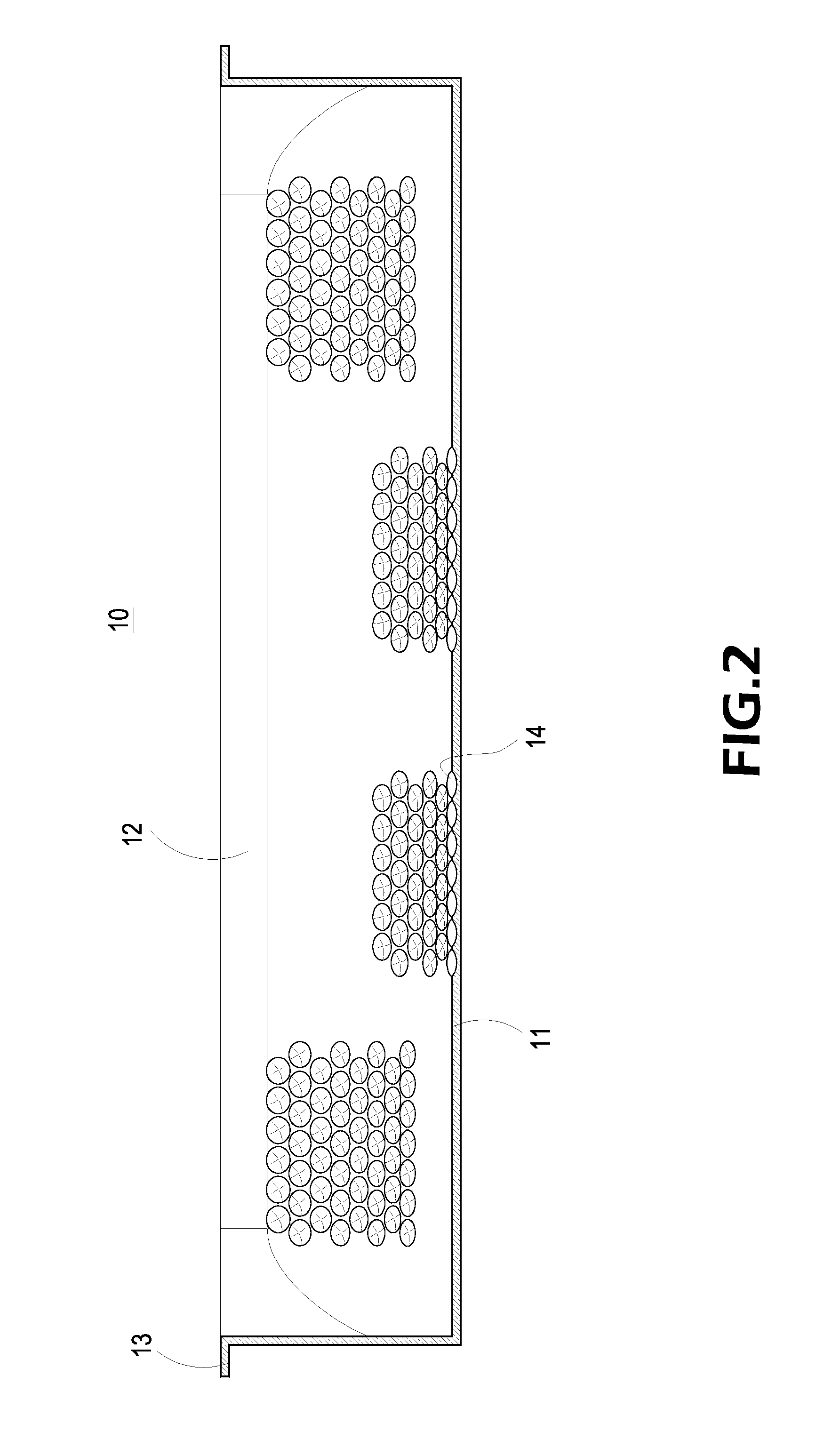

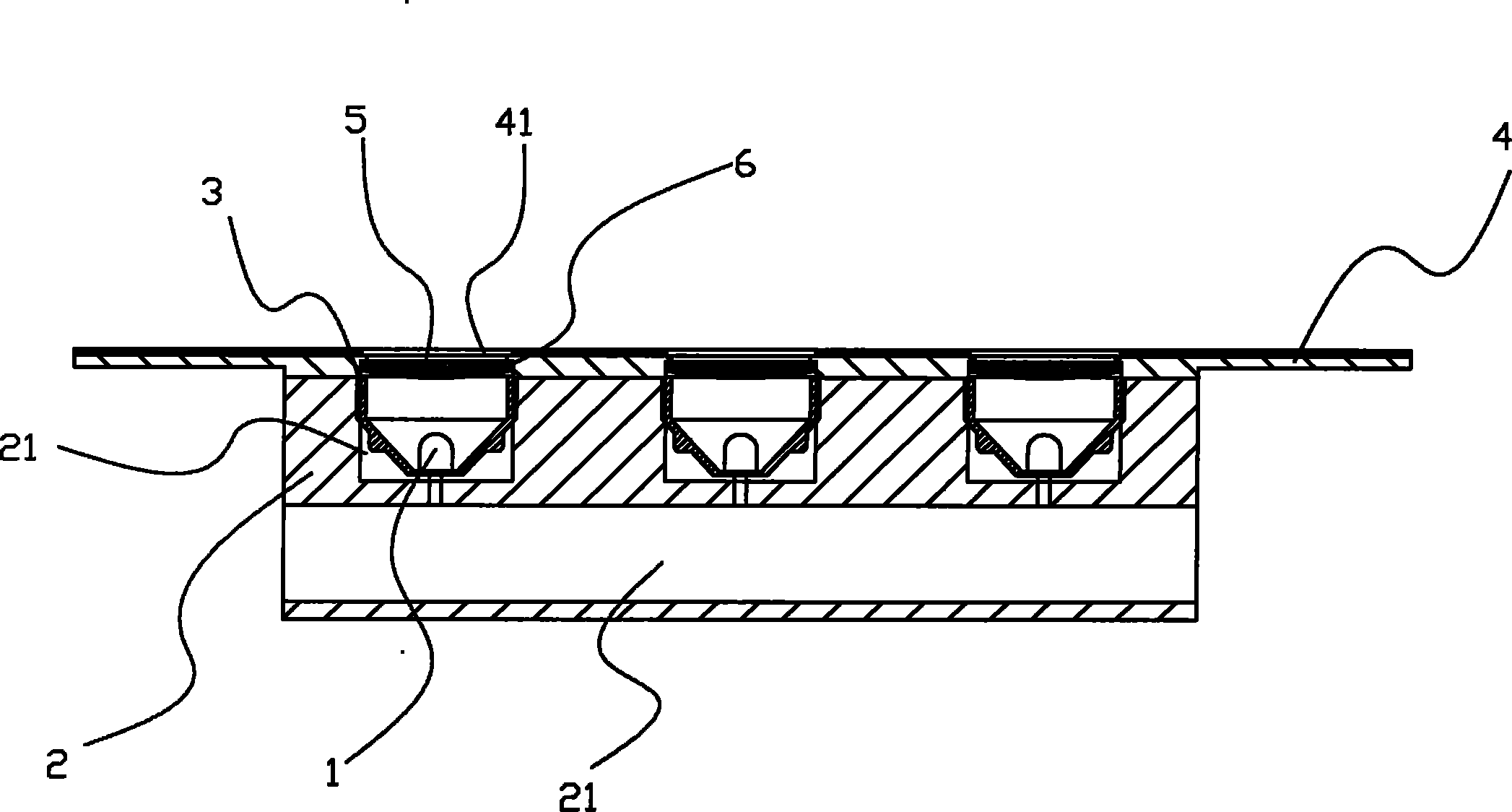

In an LED lamp illumination projecting structure, an LED lamp includes a casing, an LED lamp set and a light transmitting lens. The casing has an LED lamp set with a base board mounted in the casing and several LED lamp connected to the base board, and the light transmitting lens is installed in the light projecting direction of the LED lamp set and sealed onto a side of the casing, and several pits arranged with an interval apart and formed on the internal surface at a position corresponding to the projected position of each LED lamp for collecting and emitting the light of each LED lamp through the pit, so as to provide a better directionality of the light of the LED lamp and an evener brightness for a projecting area.

Owner:LEADER KEY +1

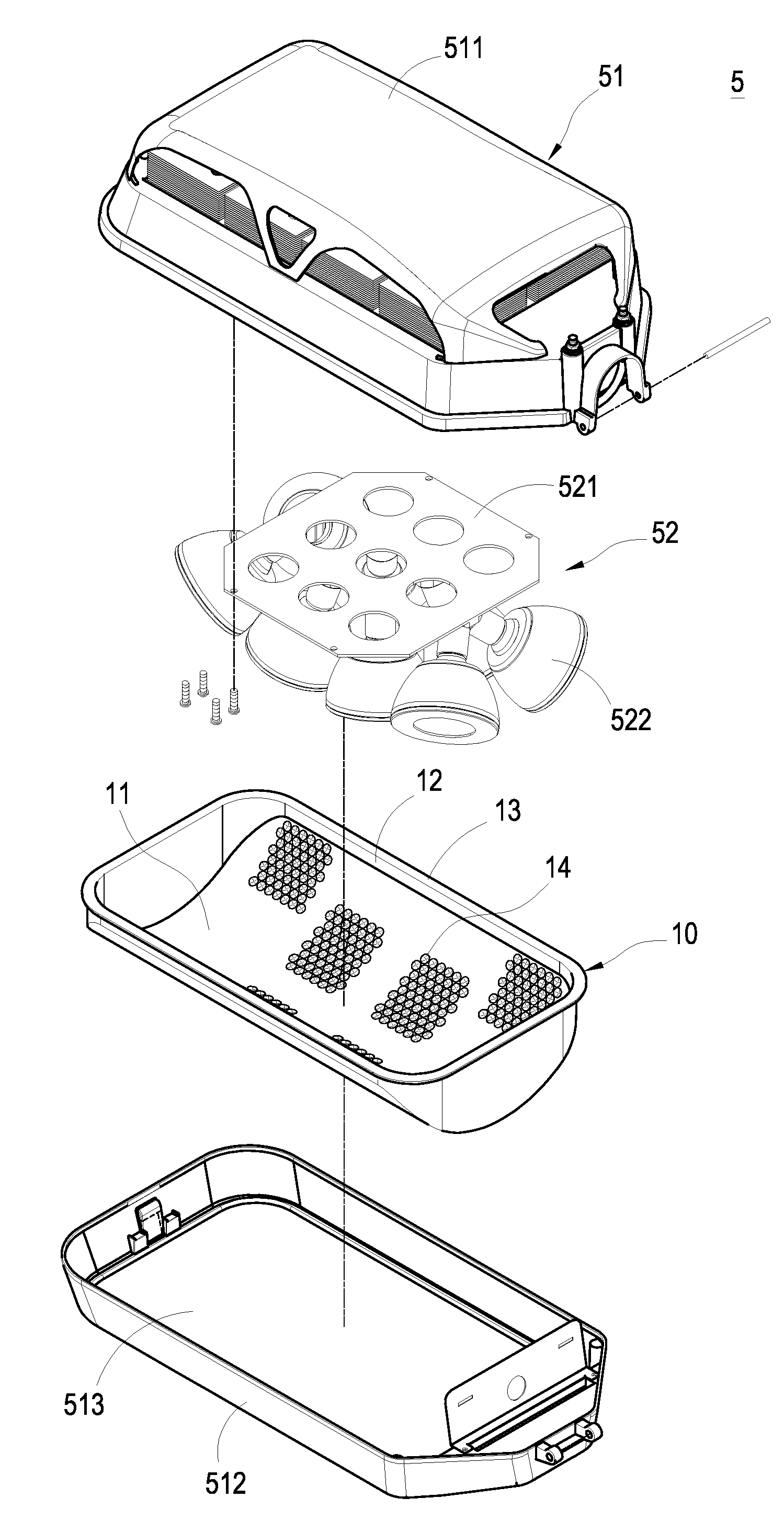

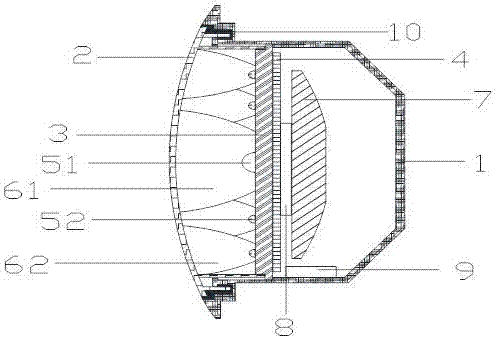

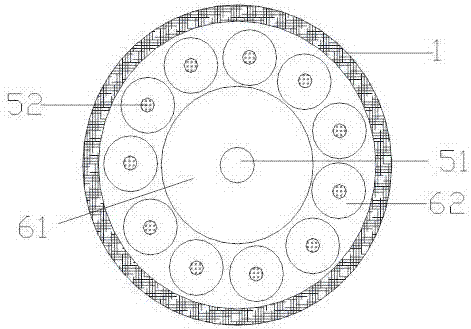

Operating astral lamp

InactiveCN101382250AEffective thickness controlLow costPoint-like light sourceTreatment roomsLight beamEngineering

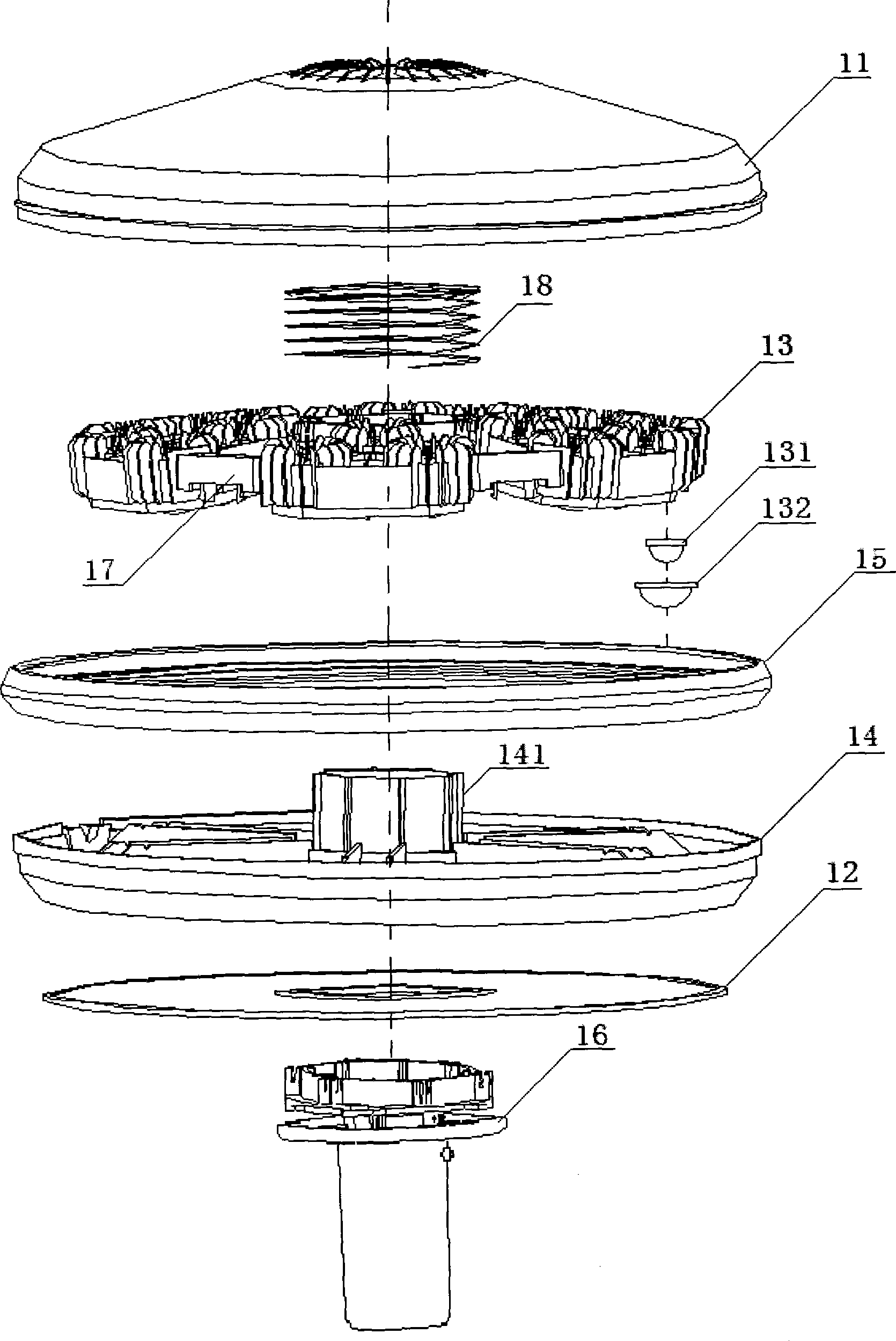

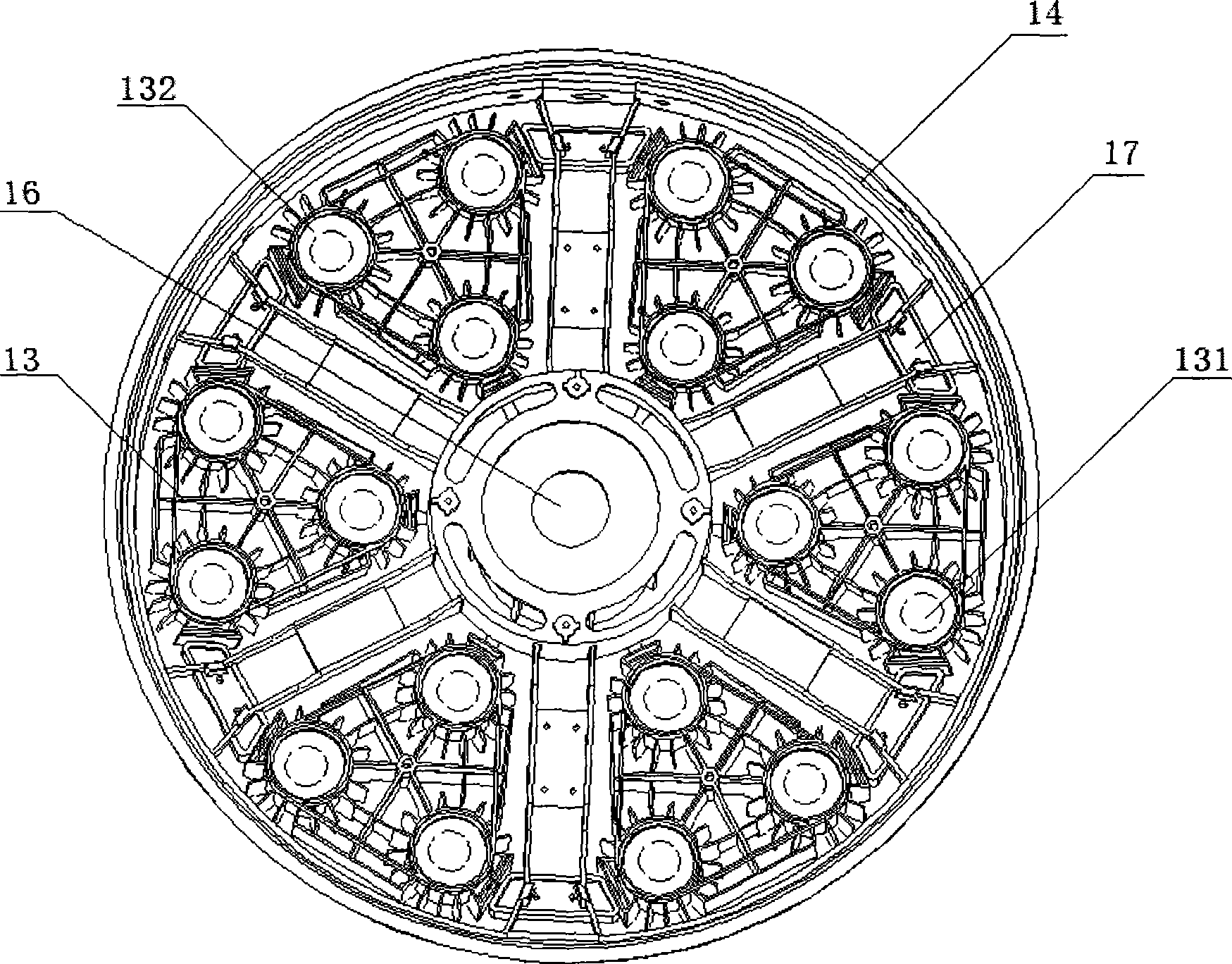

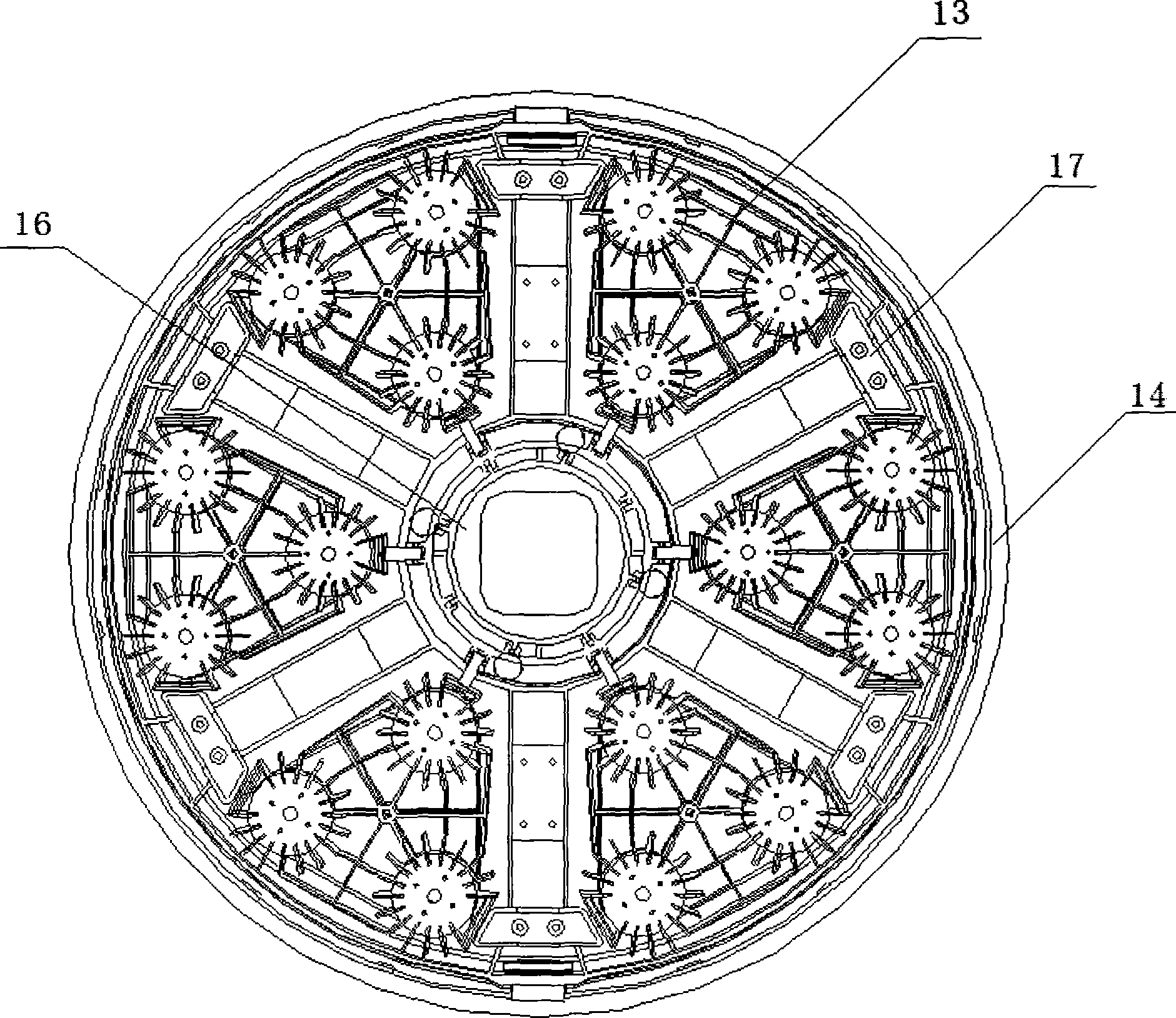

The invention provides an operating shadowless lamp, comprising at least a cover body, a lens, a plurality of light source components which are arranged between the cover body and the lens, and a bearing frame which is used for arranging the power components, wherein, the light source component is provided with a plurality of LED light sources and a plurality of convergence lenses which correspondingly cover the LED light sources; furthermore, the light beam emitted by the LED light source is directly projected to the operating position by the lens and a softening mirror; the bearing frame is provided with an exes part; a plurality of light source components are arranged in the bearing frame by surrounding the axes part; compared with the prior art, as the operating shadowless lamp adopts the LED light source, the operating shadowless lamp has the advantages of no frequency flashing, uniform luminance, ultra-long service life, safe usage, adjustable brightness, environmental protection and green energy resource, quick response speed and the like; furthermore, the operating shadowless lamp can avoid the reflector (reflector bowl), thus effectively controlling the thickness of the lamp body and reducing the production cost.

Owner:SHANGHAI PINXING SCI & TECH

Energy-saving road lamp

InactiveCN101463965AImprove light utilizationImprove antioxidant capacityElectrical apparatusElectric lighting sourcesEffect lightEngineering

The invention relates to street lamp technology field, in particular to an energy-saving street lamp, which comprises an upper cover, a lower cover, a lighting tube, an electronic ballast providing power for the lighting tube and a reflecting shade, wherein the upper cover snaps with the lower cover, the lighting tube locates between the upper cover and the lower cover, the reflecting shade is fixed between the lighting tube and the upper cover, the lower cover is equipped with a transmitting filter corresponding to the lighting tube, and the reflecting shade is equipped with a through hole for the placement of the lighting tube; the reflecting shade comprises an outer protective layer, a nanometer glistening layer and an inner protective layer, wherein the nanometer glistening layer is sprayed on the undersurface of the outer protective layer, the inner protective layer is sprayed on the undersurface of the nanometer glistening layer; as the nanometer glistening layer possesses a favorable reflection rate, namely, a higher reflection rate for visible light, and the nanometer glistening layer also possesses a favorable inoxidability, thus the weakening of the reflection rate can slow down, and the layer still possesses favorable reflection effects even though the layer services a long time, thus compared with the traditional lamp, the energy-saving street lamp of the invention consumes less electric power and possesses a longer service life.

Owner:东莞市宝利节能有限公司

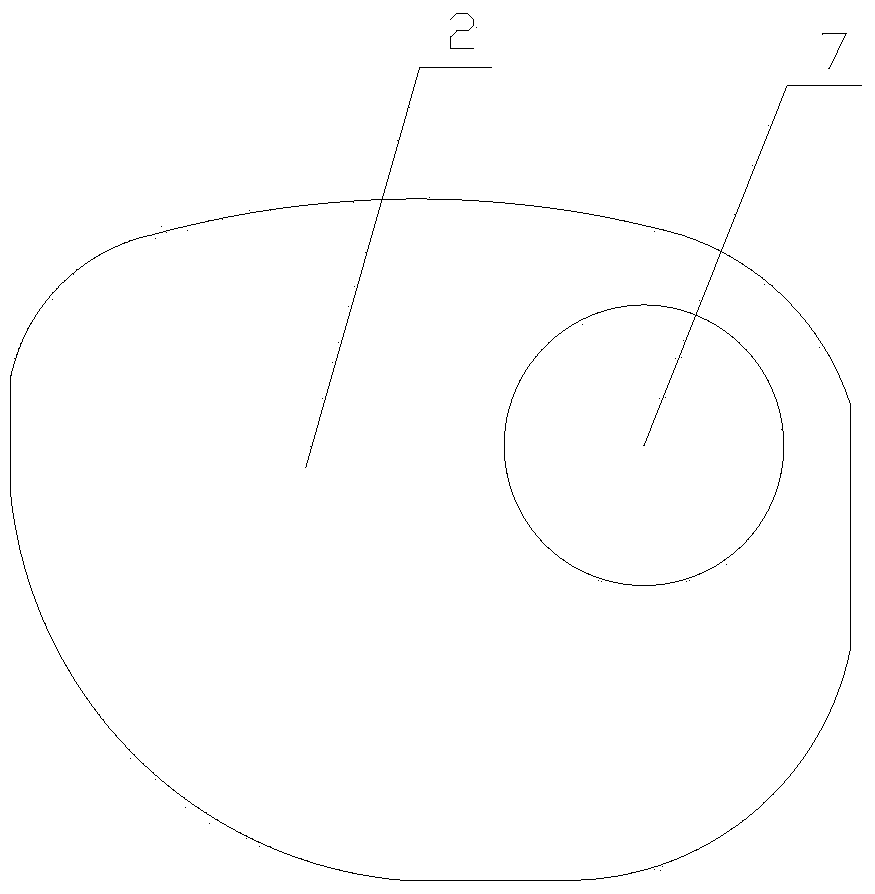

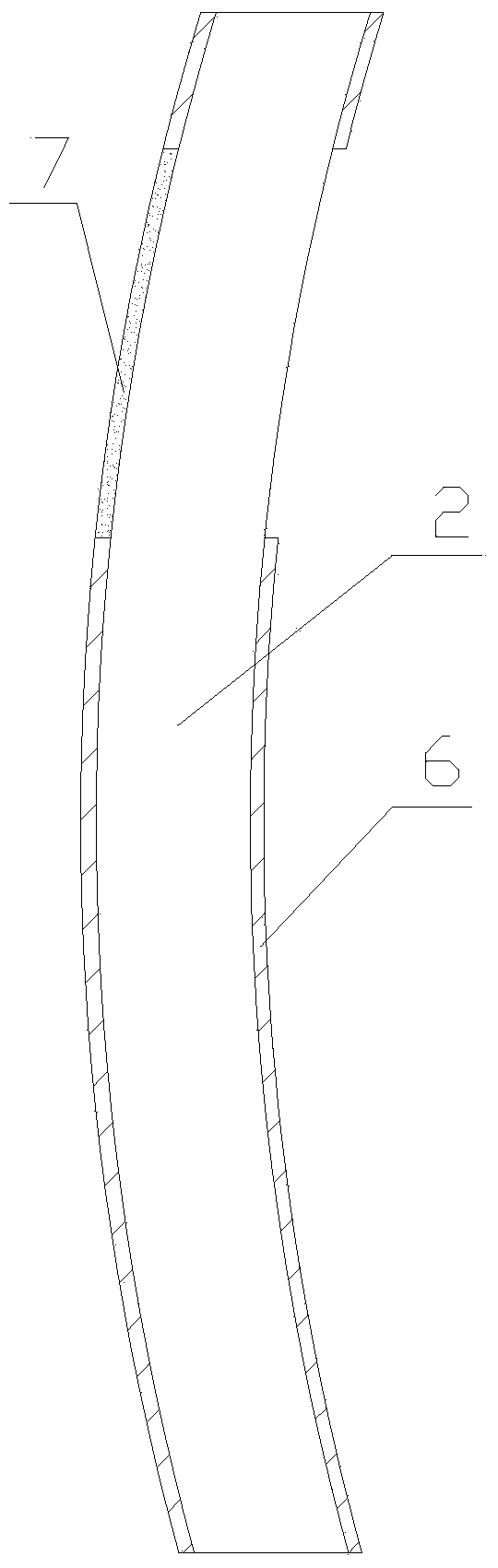

Fluorescent powder performed thin film-based LED lamp and manufacturing method thereof

InactiveCN101571238AEasy to produceSimple preparation processPoint-like light sourceElectric lightingFilm baseOptoelectronics

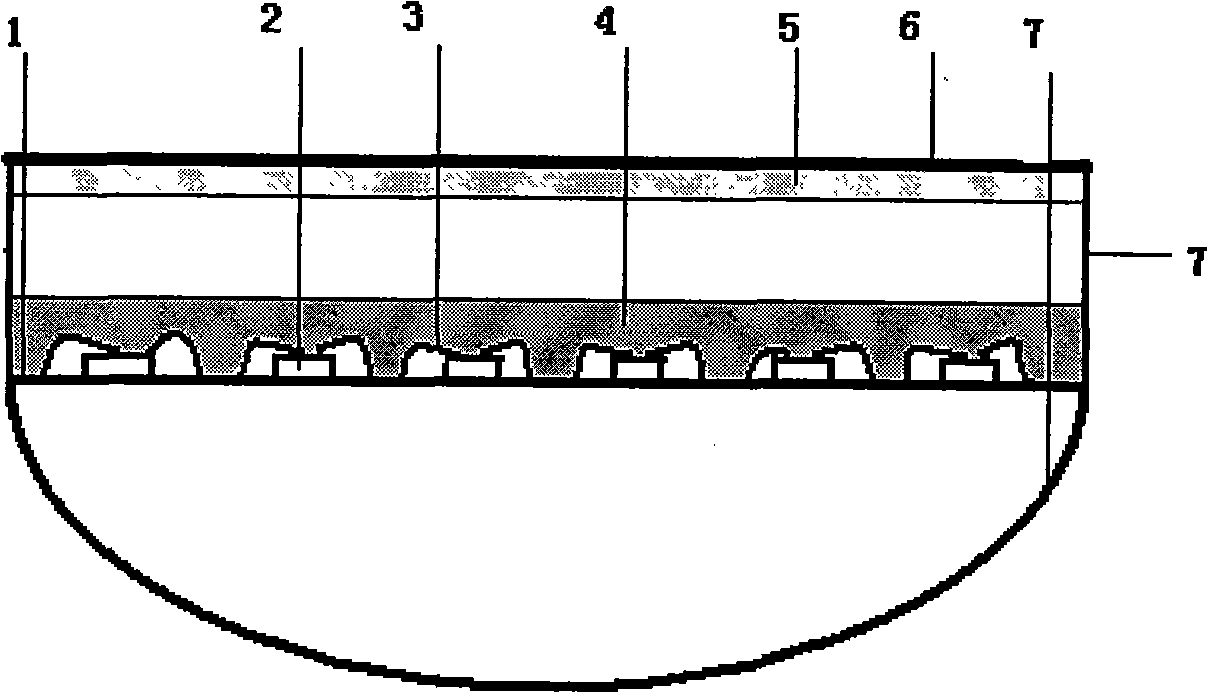

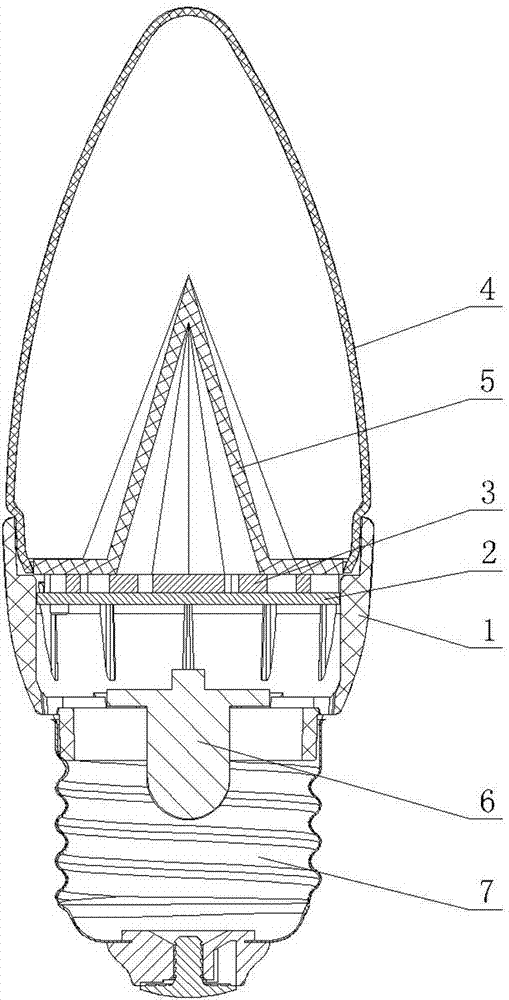

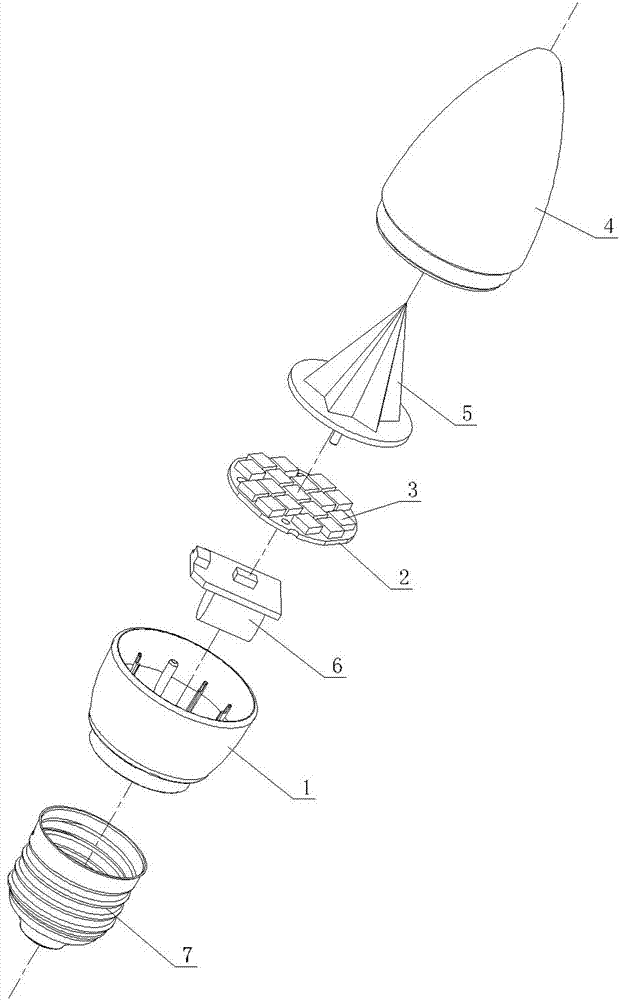

The invention relates to a fluorescent powder performed thin film-based LED lamp and a manufacturing method thereof. The LED lamp consists of a metal substrate 1, a chip 2, a gold wire 3, a binder layer 4, a fluorescent powder performed thin film layer 5, a light transmitting lens 6, a lamp shade 7 having an inner wall which is a reflector, wherein the chip 2 is fixed on the metal substrate 1; the gold wire 3 is first well connected with a circuit between the chip 2 and the metal substrate 1; an integration formed by the chip 2, the gold wire 3 and the metal substrate 1 is coated with a layer of the binder 4 to cover the metal substrate 1, the chip 2 and the gold wire 3 completely; the integration is arranged in the lamp shade 7 having the inner wall which is the reflector; the light transmitting lens 6 is arranged on the light-emitting side of the metal substrate; and the fluorescent powder performed thin film layer 5 is bonded on the inner side of the light transmitting lens 6. The LED lamp manufactured by using the packaging structure can simplify production process, improve production efficiency and greatly reduce cost and has high consistency and uniformity in various light-emitting performances.

Owner:NANJING TECH UNIV

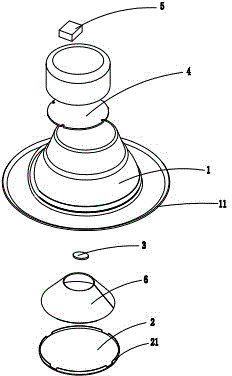

Waterproof structure of LED illuminating module

InactiveCN101776229AImprove cooling effectImprove waterproof performancePoint-like light sourceElectric circuit arrangementsRubber ringEngineering

The invention provides a waterproof structure of LED illuminating module, comprising a light-emitting diode as well as a heat sink bar internally provided with a through hole; the front face of a heat sink plate is provided with a mounting hole communicated with the through hole; the light-emitting diode is arranged in the mounting hole, a power connecting device at the tail of the light-emitting diode is connected with an external circuit via the through hole; the front face of the heat sink plate is connected with a heat sink panel, the heat sink panel is provided with an opening corresponding to the position of the mounting hole; a reflecting cup is arranged in front of the light-emitting diode in the mounting hole; a lens is arranged in front of the reflecting cup; a rubber ring is pressed between the front space of the lens and the opening of the heat sink panel. The invention adopts the semi-enclosed heat sink bar to mount the light-emitting diode, leads the wires of the light-emitting diode out via the through hole to be connected with the external circuit, while the elements such as the reflecting cup, the lens and the seal ring are fixed together by the connected heat sink panel in front, thus realizing the sealed structures of the front face and back face of the illuminating module, and having better heat sink effect simultaneously.

Owner:中山市正丰照明科技有限公司

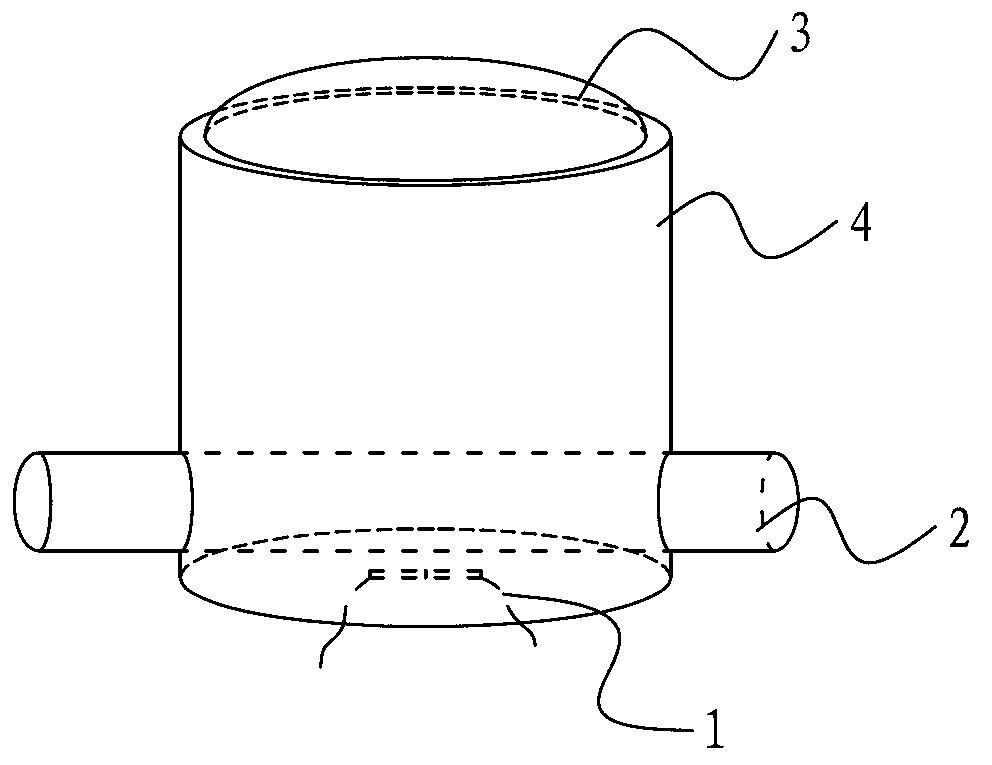

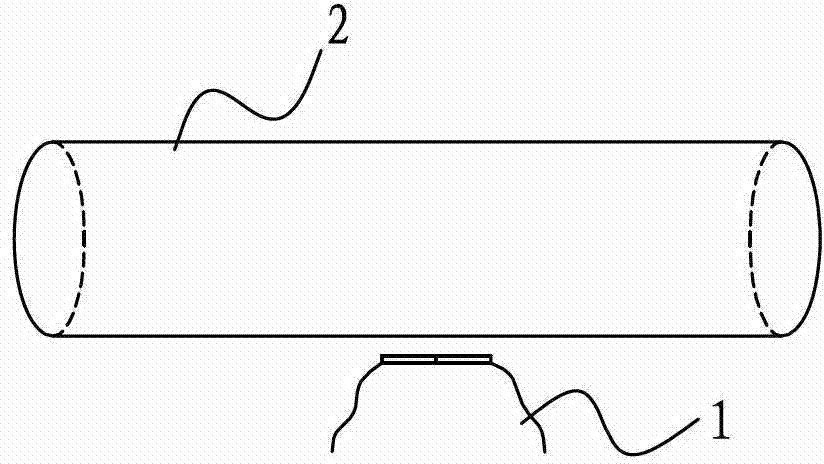

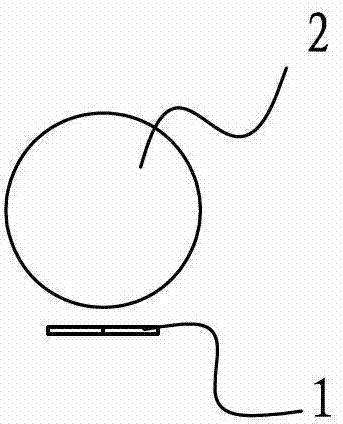

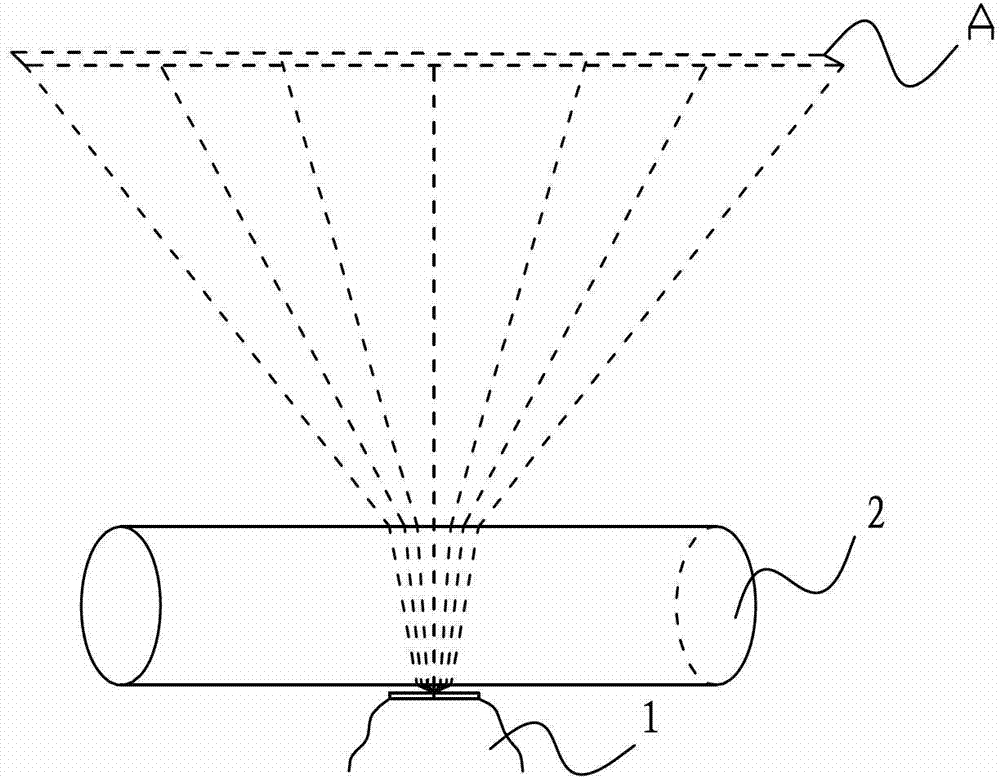

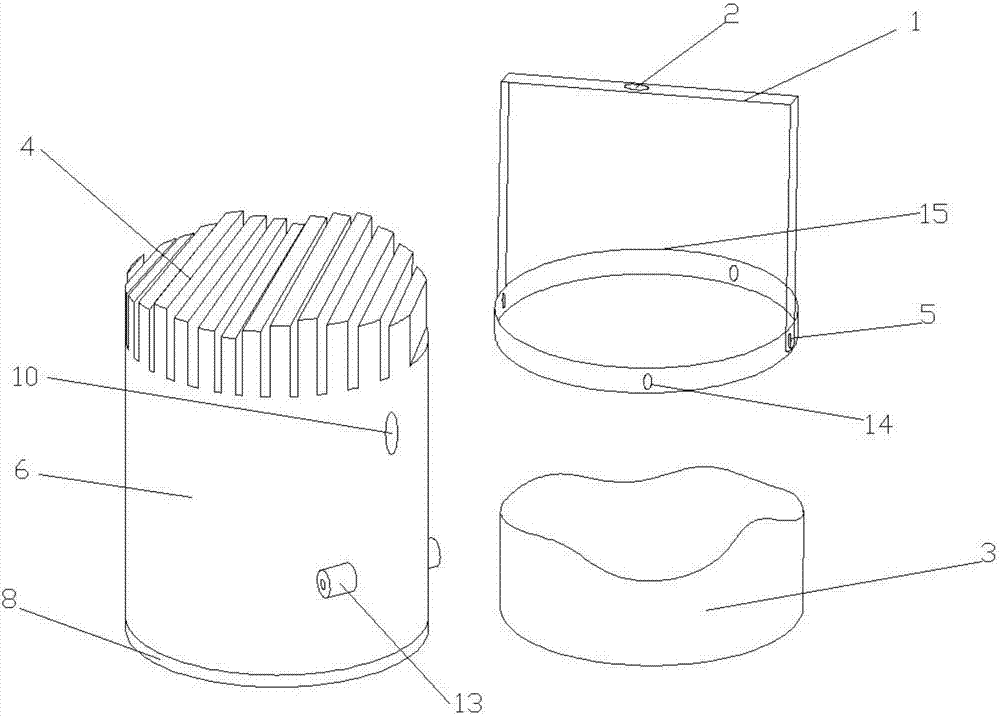

White-light illumination device based on laser excitation fluorescent powder and implementation method of white-light illumination device

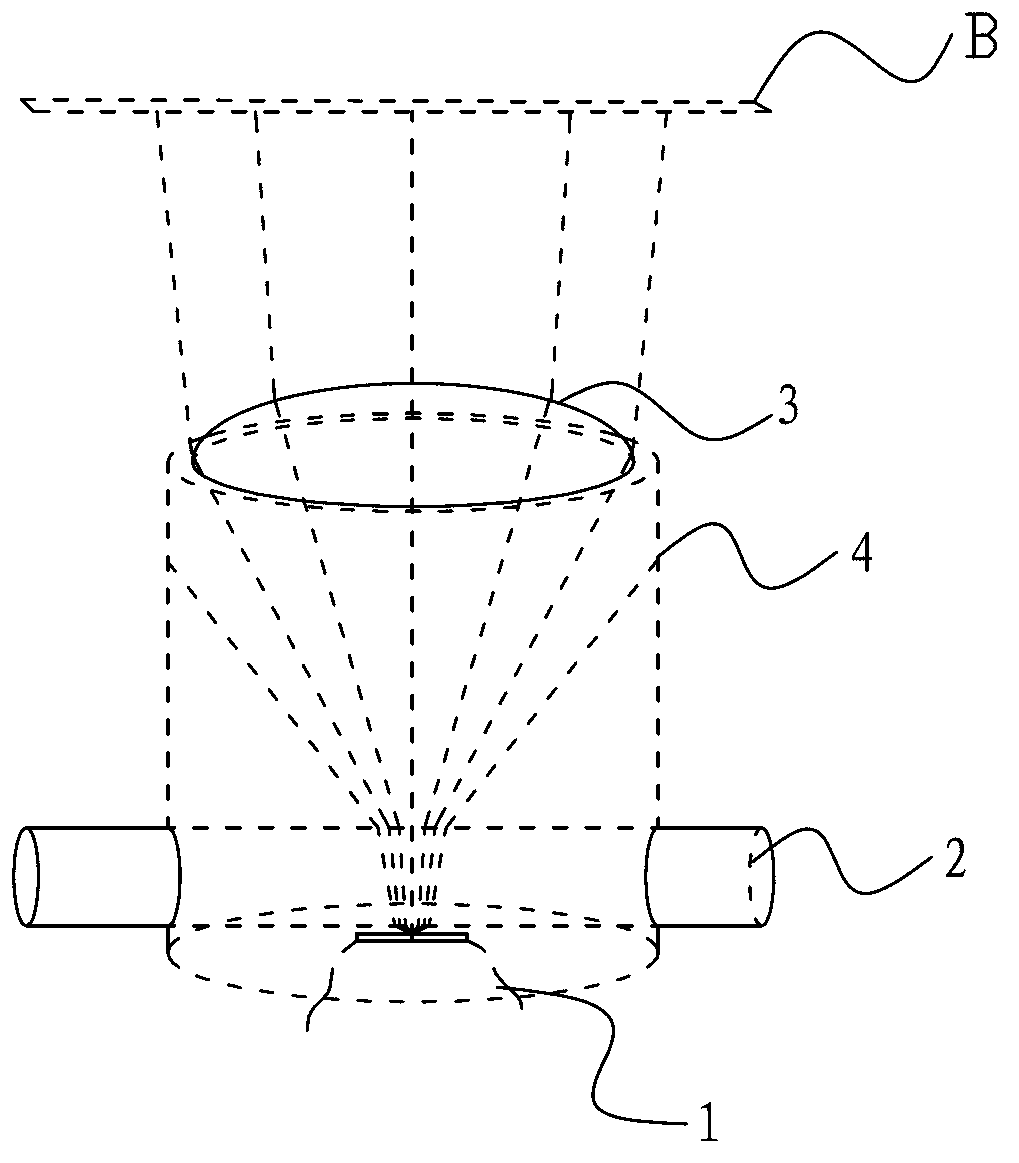

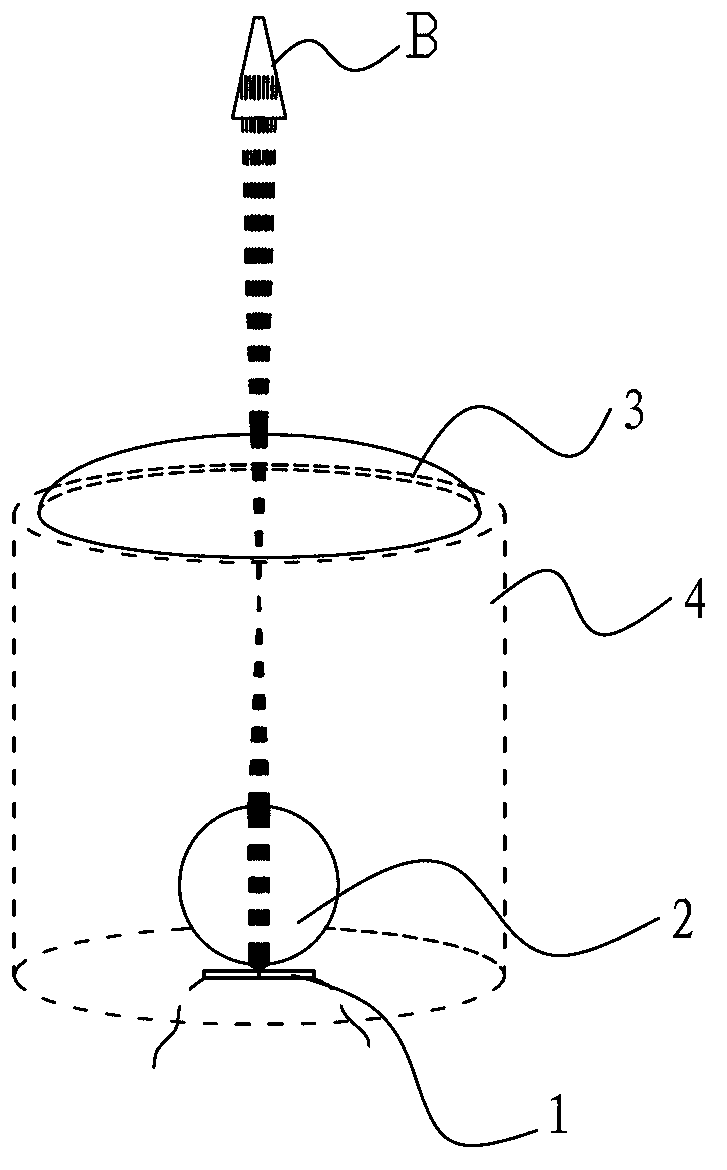

InactiveCN106764549ALess quantityHigh light conversion efficiencySpectral modifiersSemiconductor devices for light sourcesLaser lightLaser beams

The invention relates to a white-light illumination device based on laser excitation fluorescent powder. The white-light illumination device comprises a column body. An opening is formed in the side face of the column body. A laser light source is arranged at the opening. The upper portion of the column body is provided with a light output face. A reflector is arranged at the bottom of the column body. The column body is internally filled with the fluorescent powder. A laser beam is cast into the opening of the column body through a laser device. Laser illuminates the fluorescent powder located inside the column body, so that white light or monochromatic light is emitted. Part of the white light or monochromatic light is emitted along a light transmitting mirror at the top of the column body; part of the white light or monochromatic light is refracted through the reflector at the bottom of the column body and then emitted through the light transmitting mirror; and due to the total reflection principle, part of unabsorbed laser can continue to excite the fluorescent powder inside the column body, and white light or monochromatic light is generated through excitation continuously. By means of the white-light illumination device, the problem that the fluorescent powder is overheated is effectively solved; the light output face can be changed; a small amount of fluorescent powder is needed; the structure is varied and simple; and production cost is effectively lowered.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

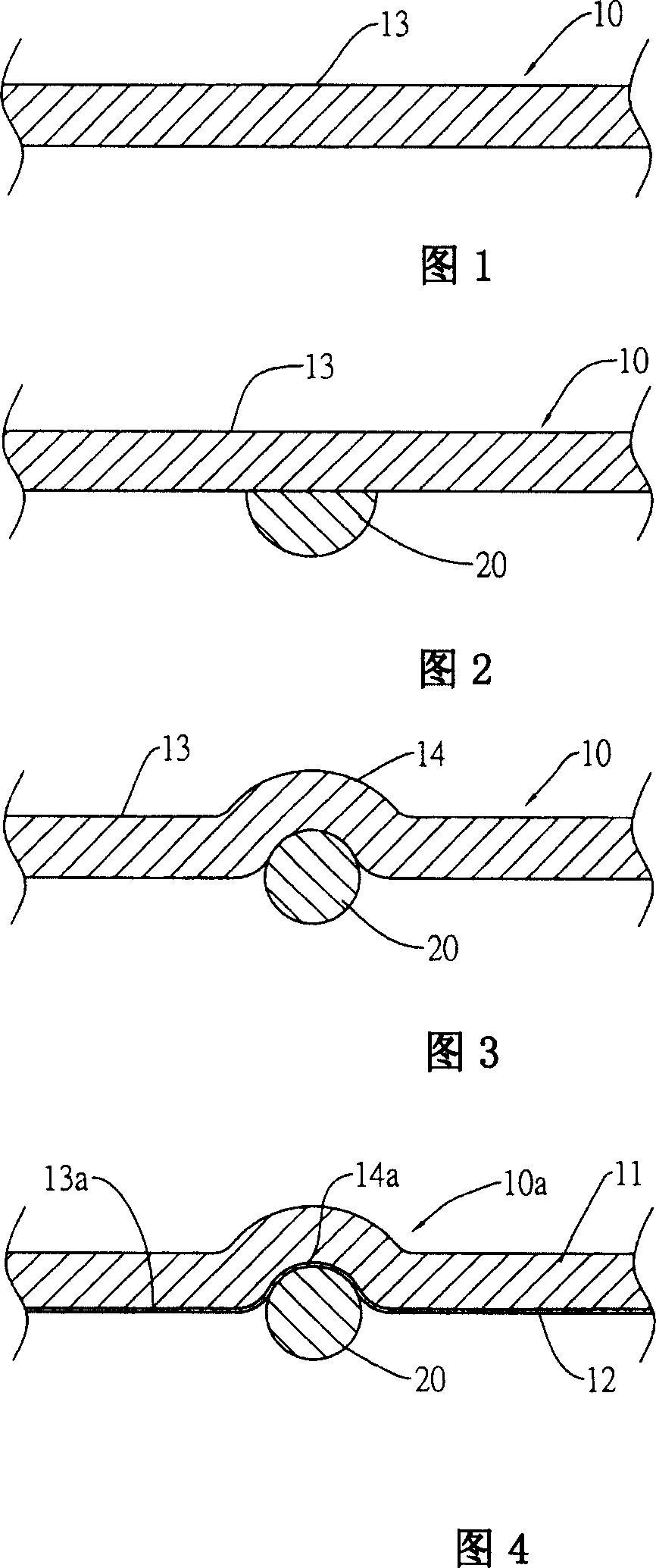

Pre-packaged LED illuminating lamp and manufacture method thereof

InactiveCN101526179ASimple packaging processSolve the problem of poor light consistencyPoint-like light sourceElectric lightingThin layerEngineering

The invention provides a pre-packaged LED illuminating lamp which comprises independent LED lamps 8, a prefabricated film layer 7 of fluorescent powder and binding agent, a lampshade 9 and a transmission mirror 6, wherein at least one independent LED lamp is fixed in the lampshade; the transmission face of the lampshade is provided with the transmission mirror, and the prefabricated thin layer of fluorescent powder and binding agent is bonded inside the transmission mirror; and the independent LED lamps 8 do not contain the fluorescent powder. The LED illuminating lamp manufactured by the packaged structure has high consistency and uniformity of different transmission performances, simplifies the production technique and enhances the production efficiency simultaneously. The packaged structure can be widely applied to the production of various LED illuminating lamps.

Owner:NANJING UNIV OF TECH

LED display screen, full-color LED light-emitting panel and manufacturing method of full-color LED light-emitting panel

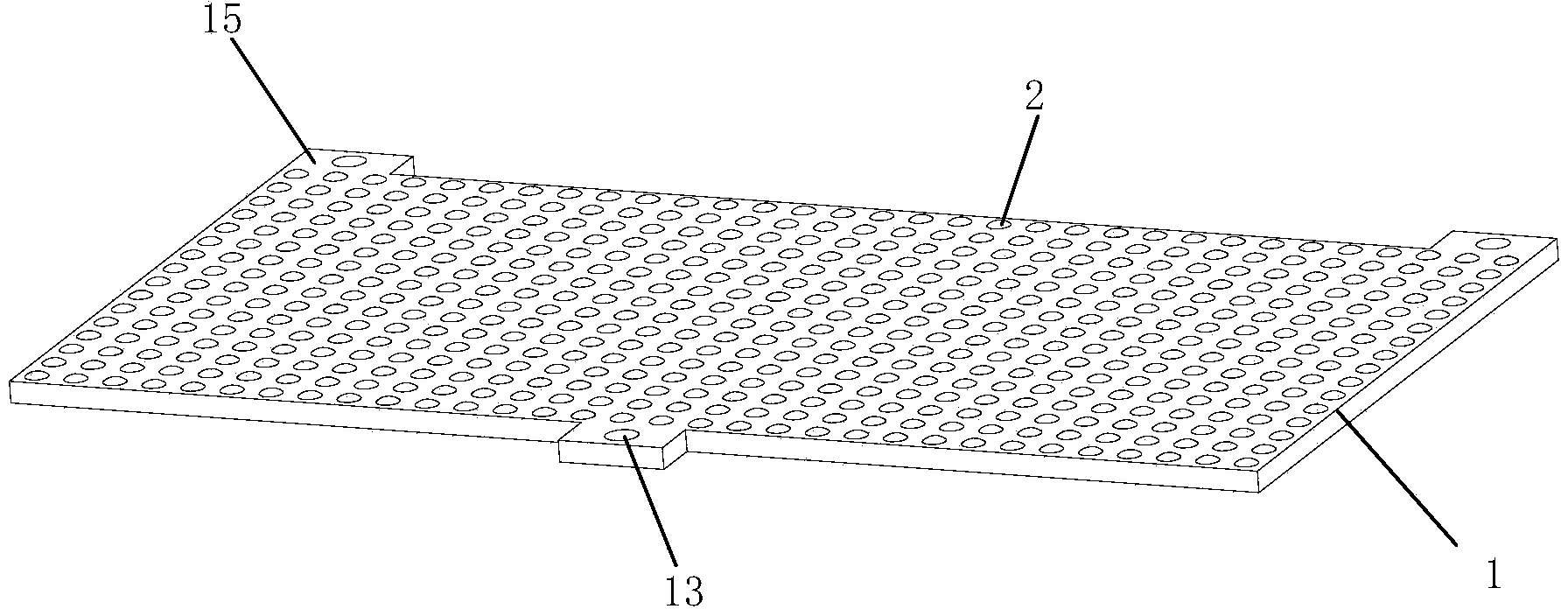

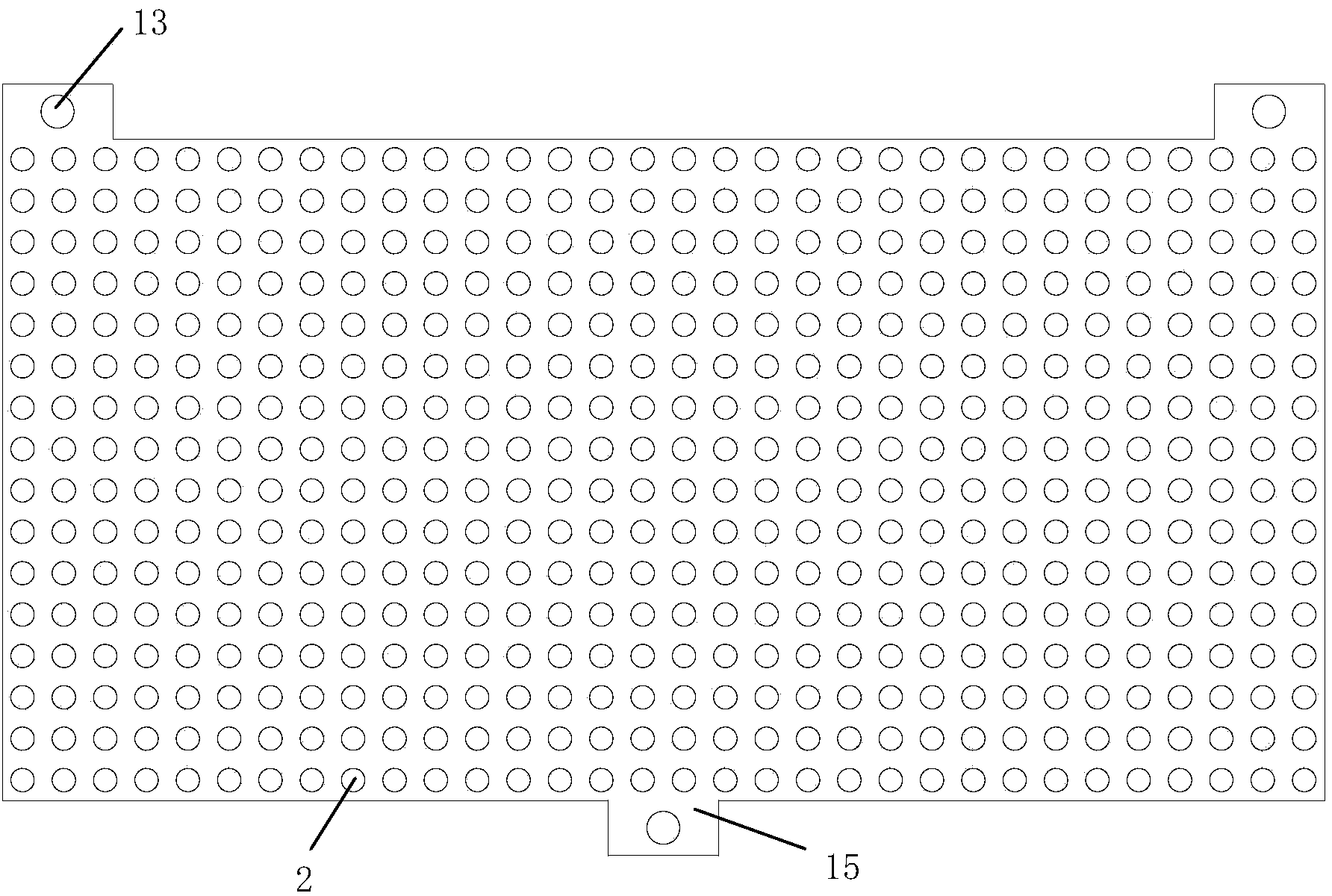

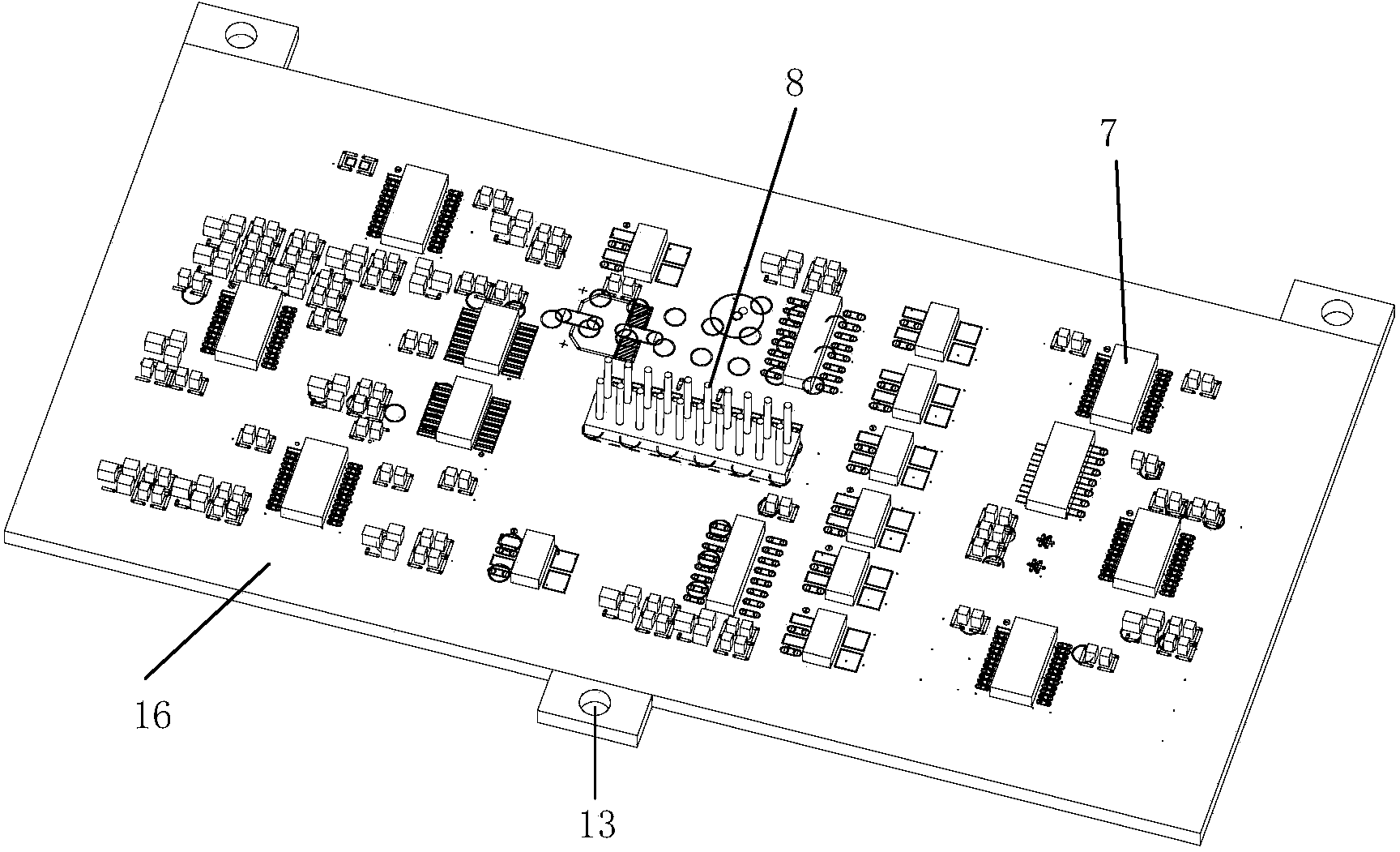

The invention discloses an LED display screen, a full-color LED light-emitting panel and a manufacturing method of the full-color LED light-emitting panel. The LED display screen comprises a circuit board, an LED lamp array arranged on the circuit board, and a drive circuit arranged on the circuit board. The circuit board comprises a first face and a second face, wherein the first face and the second face are opposite. The LED lamp array is arranged on the first face of the circuit board, and the drive circuit is arranged on the second face of the circuit board. A concave hole array is formed in the first face, and a plurality of immersion gold welding plates are arranged at the bottom of each concave hole. The LED lamp array is a full-color LED lamp array, and each full-color LED lamp is packaged in the corresponding concave hole. Each full-color LED lamp comprises LED light-emitting wafers which are in three colors and are fixed to the corresponding immersion gold welding plates in a binding mode, and lenses which are formed on the corresponding LED light-emitting wafers in three colors in an epoxy potted mode and a covering mode to seal the corresponding concave holes. The LED display screen and the full-color LED light-emitting panel can be widely applied to indoor full-color display in a small distance.

Owner:SHENZHEN AUROLED TECH

Spectacles with visual angle of 360 degrees

The invention provides a pair of spectacles with a visual angle of 360 degrees. The pair of spectacles comprises a spectacle frame body, wherein lenses are arranged on the spectacle frame body; the spectacle frame body comprises a lens frame part and high-light-transmission spectacle leg parts; spectacle angle elbows are arranged at two ends of the lens frame part and are hinged to the spectacle leg parts; a reflecting layer is plated at the inclined upper corner of the outer side of each lens in a vacuum manner. The pair of spectacles is simpler in structure, lighter in weight, convenient to carry, relatively concealed, and good in reflecting effect; a user can observe 360-degree surrounding images with eyes or can clearly, accurately and completely capture the 360-degree images after slightly turning, so that front, rear and back images at 360 degrees can be noticed. Thus, the pair of spectacles is particularly suitable for searching offenders by security officers such as policemen in all directions, the tracking behaviors of some criminals can be prevented when an ordinary user walks alone, and the pair of spectacles is applicable to users of all ages.

Owner:徐正华

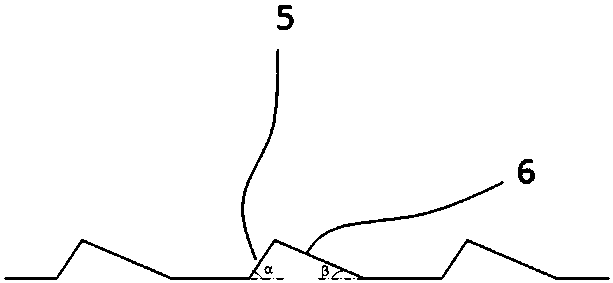

Spotlight with double lens for generating rectangular light spots

InactiveCN102798041AConcentratedReduce light lossRefractorsFixed installationLight spotOptoelectronics

The invention discloses a spotlight with double lens for generating rectangular light spots, and the spotlight comprises a light source. The spotlight is characterized in that a cylindrical light-transmitting lens used for converging the scattered rays emitted by the light source, and enabling the light spots formed by irradiating the rays emitted by the light source on an irradiated body to be rectangular light spots is arranged on the front part of the light source; and a convex lens used for further converging the rays is arranged at the front end of the cylindrical light-transmitting lens. A light-shielding barrel is arranged between the cylindrical light-transmitting lens and the convex lens. The convex lens is fixed on the top of the light-shielding barrel, and the cylindrical light-transmitting lens is fixed on the bottom of the light-shielding barrel. By virtue of the refraction principle and the reflection principle of rays, the scattered rays are collected in a rectangular range by using the lenses, so as to generate the rectangular light spots. Compared with the prior art, the spotlight disclosed by the invention has the advantages of being wide in application range, centralized in light convergence, high in brightness, and less in light loss. In addition, the spotlight is convenient in production, low in cost, and suitable for wide popularization.

Owner:DALIAN XINQIHUI TECH

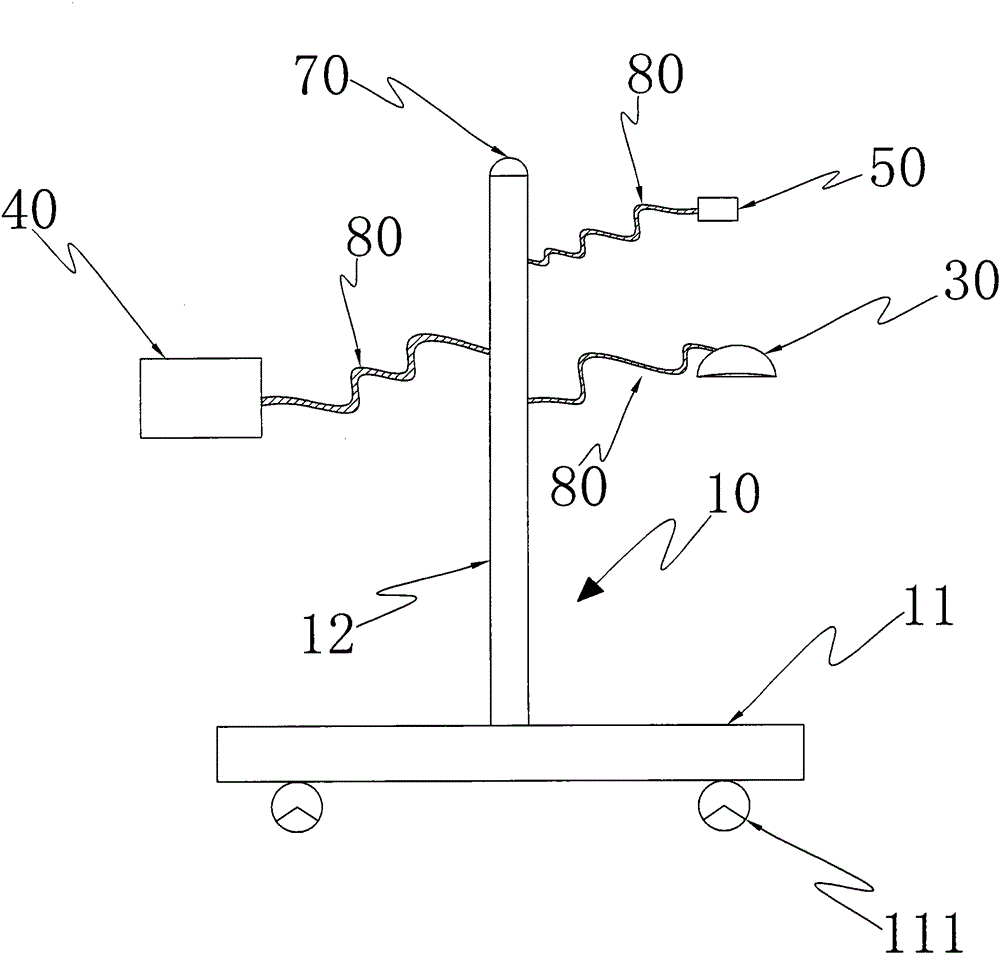

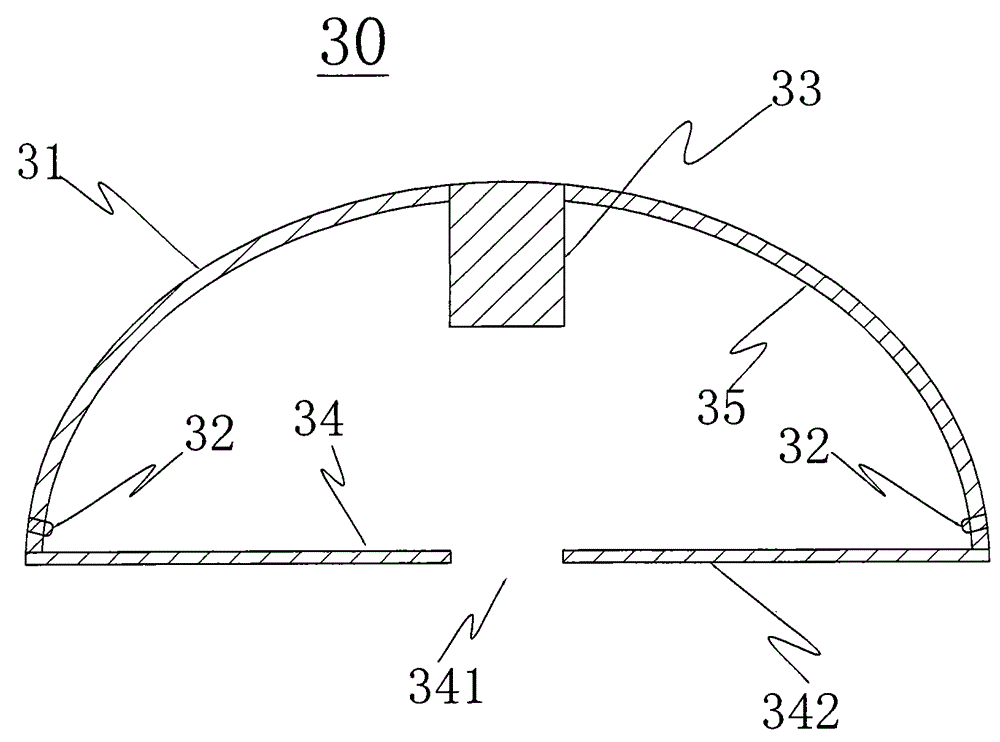

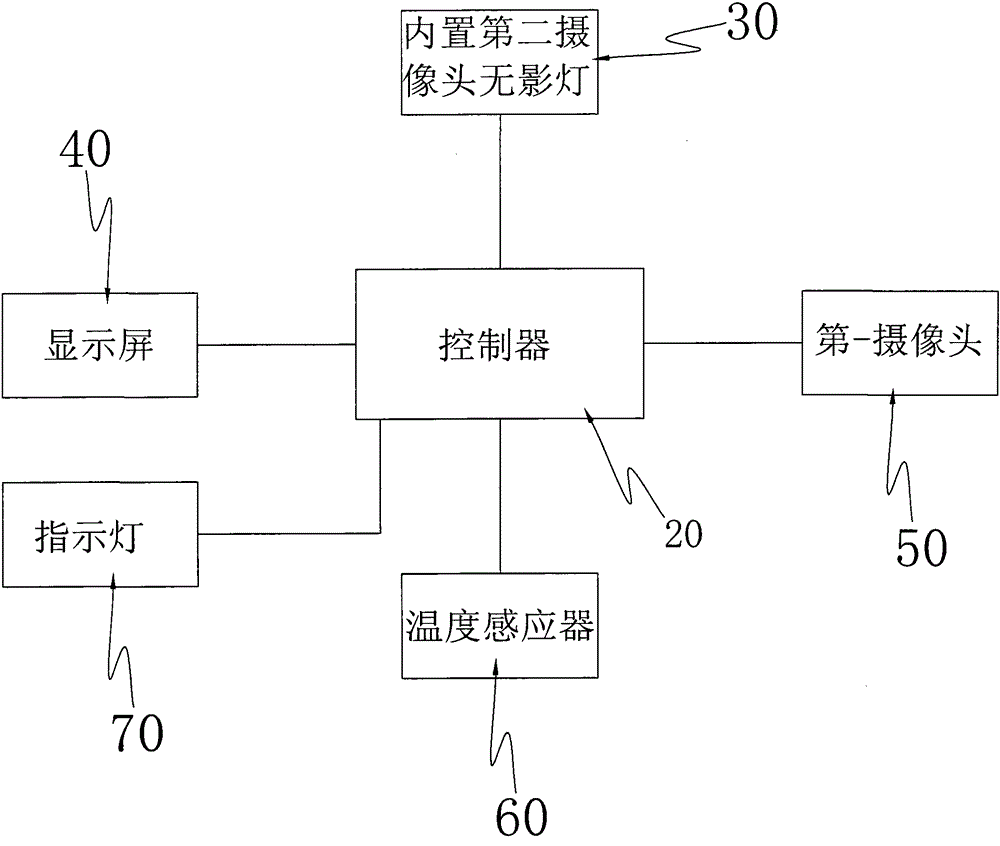

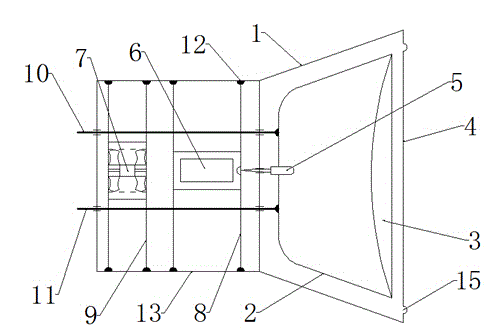

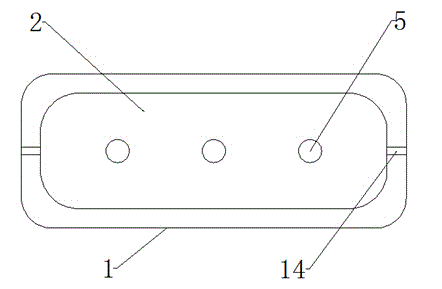

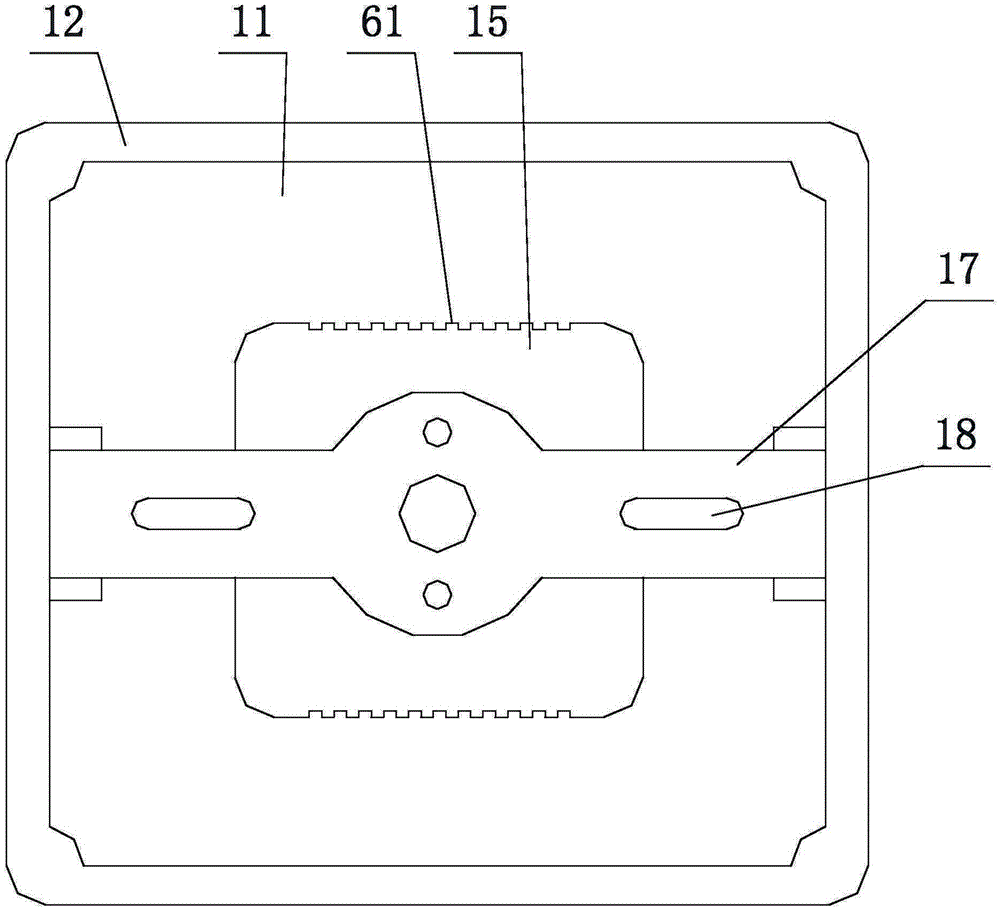

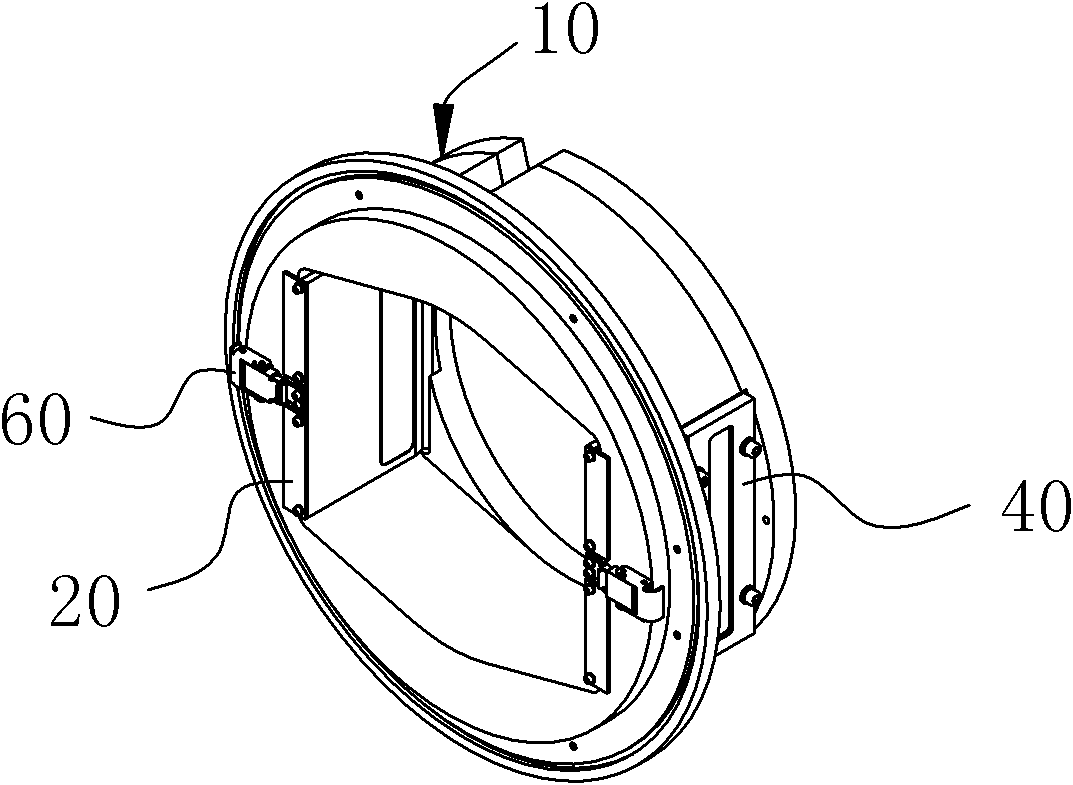

Anti-dazzle visual operating room shadowless lamp system

InactiveCN105042342ANo impactMeet the temperaturePoint-like light sourceLighting support devicesInfraredRoom temperature

The invention discloses an anti-dazzle visual operating room shadowless lamp system. The anti-dazzle visual operating room shadowless lamp system comprises a substrate, a main controller, a shadowless lamp and a display screen, wherein the shadowless lamp and the display screen are connected with the main controller. The substrate is provided with a first camera. The shadowless lamp comprises a lampshade, an LED lamp, a second camera and a light-transmitting mirror installed on the bottom of the lampshade. The LED lamp is installed on the inner side wall of the lampshade to form an annular light source emitting light laterally. The second camera is installed in the lampshade and connected with the main controller. A cold light reflecting film is arranged on the inner side surface of the lampshade. The light-transmitting mirror is provided with an open hole facing the second camera, and an infrared filtering film is arranged on the outer surface of the light-transmitting mirror. Thus, the operation range can be extended by installing the multiple cameras, remote consultation can be promoted more effectively, the anti-dazzle effect can be achieved, impact to the vision of surgical doctors is avoided, the better cold light effect can be achieved, the requirement of the operating room temperature can be met, and infrared rays can be filtered out effectively.

Owner:HUBEI FEIGOT MEDICAL TECH CO LTD

Car lamp

InactiveCN105371195AImprove lighting effectsExtended service lifePoint-like light sourceLighting heating/cooling arrangementsFixed frameRoad condition

The invention discloses a car lamp. The car lamp is provided with three LED light sources. The lighting effect is increased through a reflector and a light transmitting mirror. A rear cover is connected with the reflector through a rotary shaft. The upper portion and the lower portion of the left end of the reflector are connected with an upper guide rod and a lower guide rod through screws respectively. The upper guide rod and the lower guide rod penetrate a base to be connected with a transmission device and can move left and right to drive the reflector to vertically rotate. The front road of a car can be irradiated more flexibly, and the driving safety coefficient is increased. A fan fixing frame is fixed to the left end of the base through a screw, a fan is arranged in the center of the fan fixing frame and used for cooling, and the service life of the car lamp is prolonged. The car lamp is novel in model, easy to model and very high in usability, and the requirements of the car running on different road conditions can be met.

Owner:刘平

Method for manufacturing light transmitting magic mirror through injection molding and plating

InactiveCN102217871AEasy to manufacturePicture framesDomestic mirrorsPlastic injection moldingCharacter design

The invention discloses a method for manufacturing a light transmitting magic mirror with light transmitting effect similar to that of the light transmitting magic mirror in Western Han Dynasty in Ancient China through injection molding of plastics and then plating of a layer of metal. Besides the same functions of a common mirror, the light transmitting mirror in Western Han Dynasty can also reflect the ornamentations and characters on the back side of the mirror when reflecting the sunlight; therefore, the light transmitting mirror in Western Han Dynasty is called magic mirror in the ancient times. The phenomenon that a plastic product has different curvatures at different mirror body thicknesses during injection molding and forming is adopted, and plastic injection-molding and forming are adopted to manufacture a plastic mirror billet with light transmitting effect; then a plastic plating method is used for plating a layer of metal on the plastic mirror billet; in the way, the magic mirror with the light transmitting effect is imitated. The method for manufacturing light transmitting magic mirror can be used for manufacturing travel products designed with images like religious figures, leaders, animal and plant floral designs, character designs, etc.

Owner:史祖法 +1

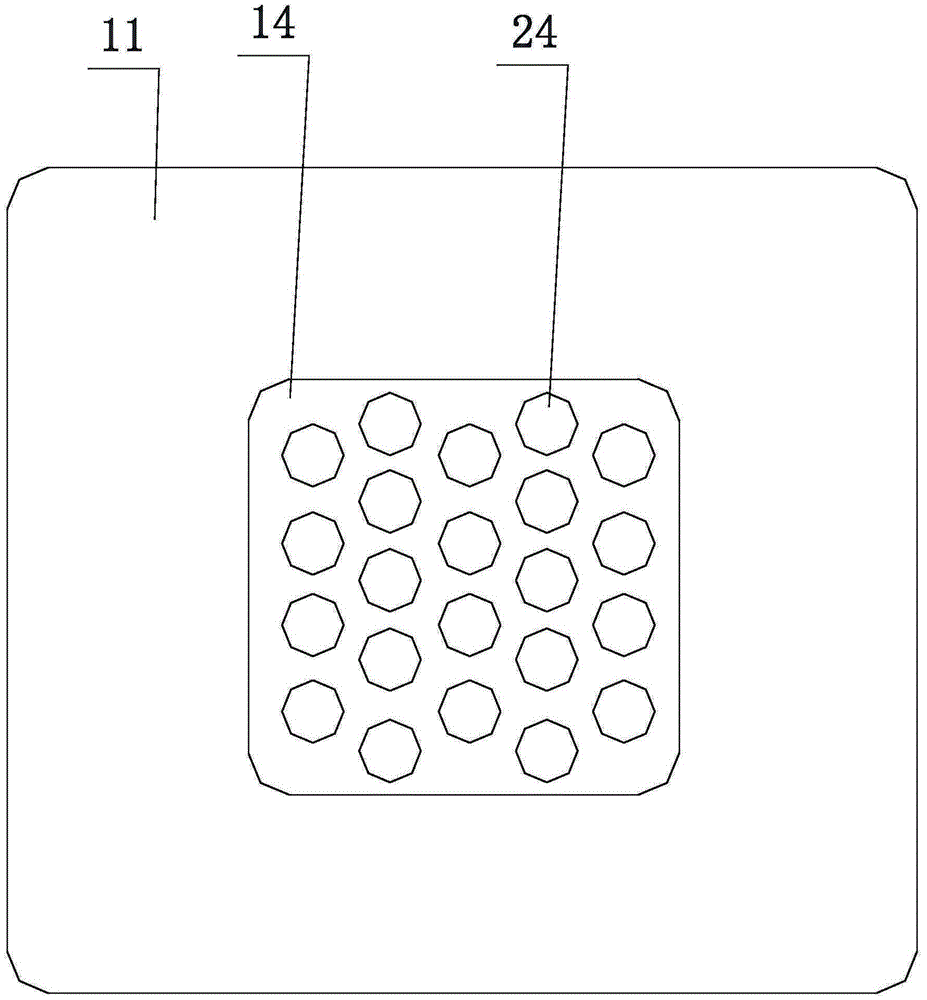

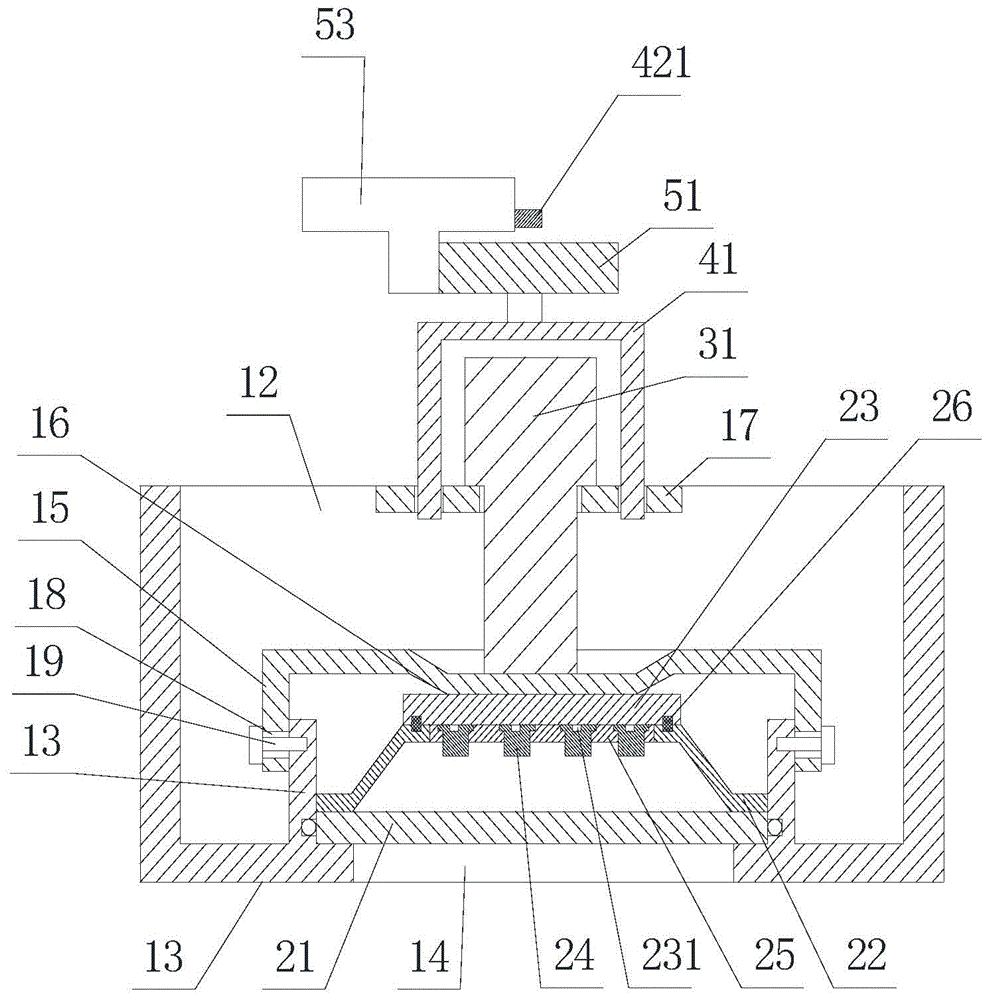

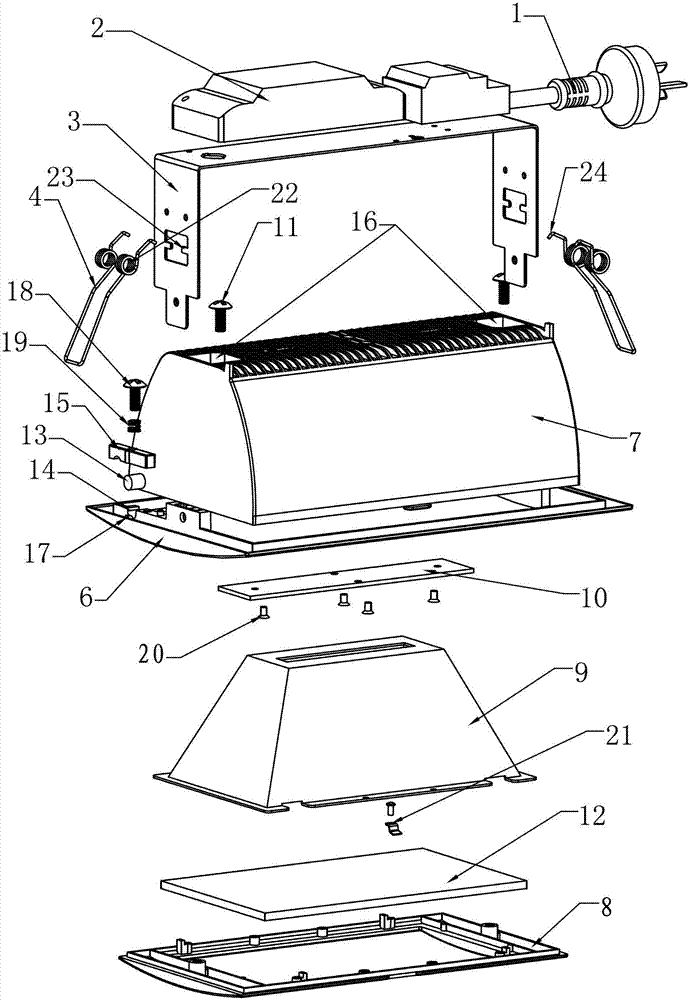

Square hole lamp

ActiveCN104132270AStable structureFlexible rotationLighting heating/cooling arrangementsElectric lightingEngineeringLamp shell

The invention provides a square hole lamp which comprises a lamp shell. The lamp shell is formed by a bottom plate, an outer ring arranged at the top face of the bottom plate and an inner ring arranged at the top face of the bottom plate. The inner ring is arranged in the outer ring. The inner ring is lower than the outer ring. A light-out hole is formed in the middle of the bottom plate. A face plate, a reflecting cup and a lamp plate are arranged in the inner ring from bottom to top in sequence. A cover plate is arranged at the top of the inner ring in a covering mode. An anti-separating structure which prevents the inner ring and the cover plate from being separated is arranged between the inner ring and the cover plate. The inner top face of the cover plate is provided with a protrusion which abuts against the top face of the lamp plate. A lamp grain is arranged on one side, toward the reflecting cup, of the lamp plate. A light transmission mirror is arranged on the lamp grain in a covering mode. A blocking plate is arranged on the lamp plate in a covering mode. An elastic part is arranged between the top face of the reflecting cup and the lamp plate. The elastic part has action force which drives the reflecting cup and the lamp plate to be separated. The periphery outer wall of the face plate is matched with the inner ring in a sealing mode. The structure is firm, the light condensation degree can be adjusted according to needs, rotating is flexible, and the square hole lamp is very suitable for light casting in a large show place.

Owner:ZHEJIANG CHANGXING JINSHENG ELECTRO OPTIC TECH

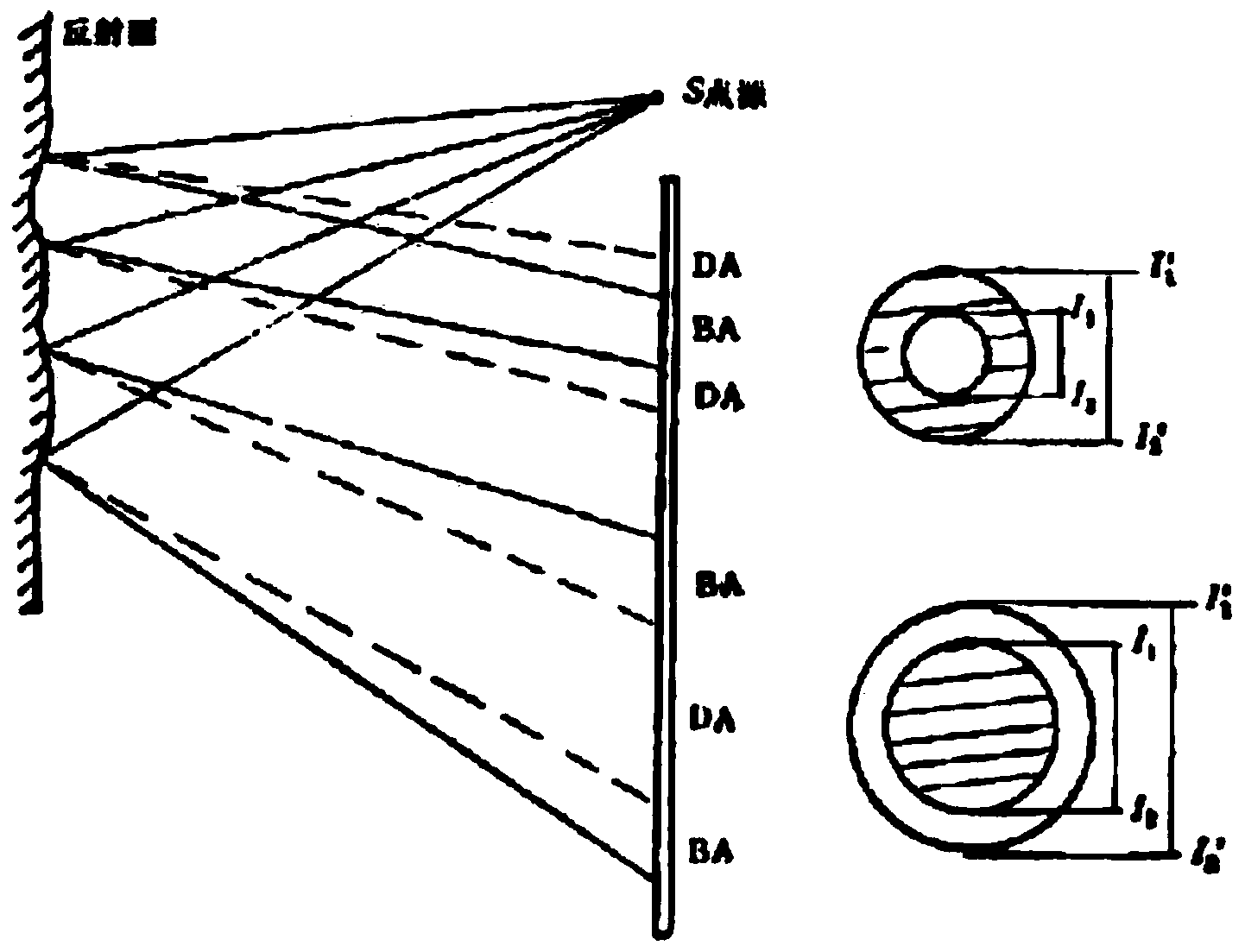

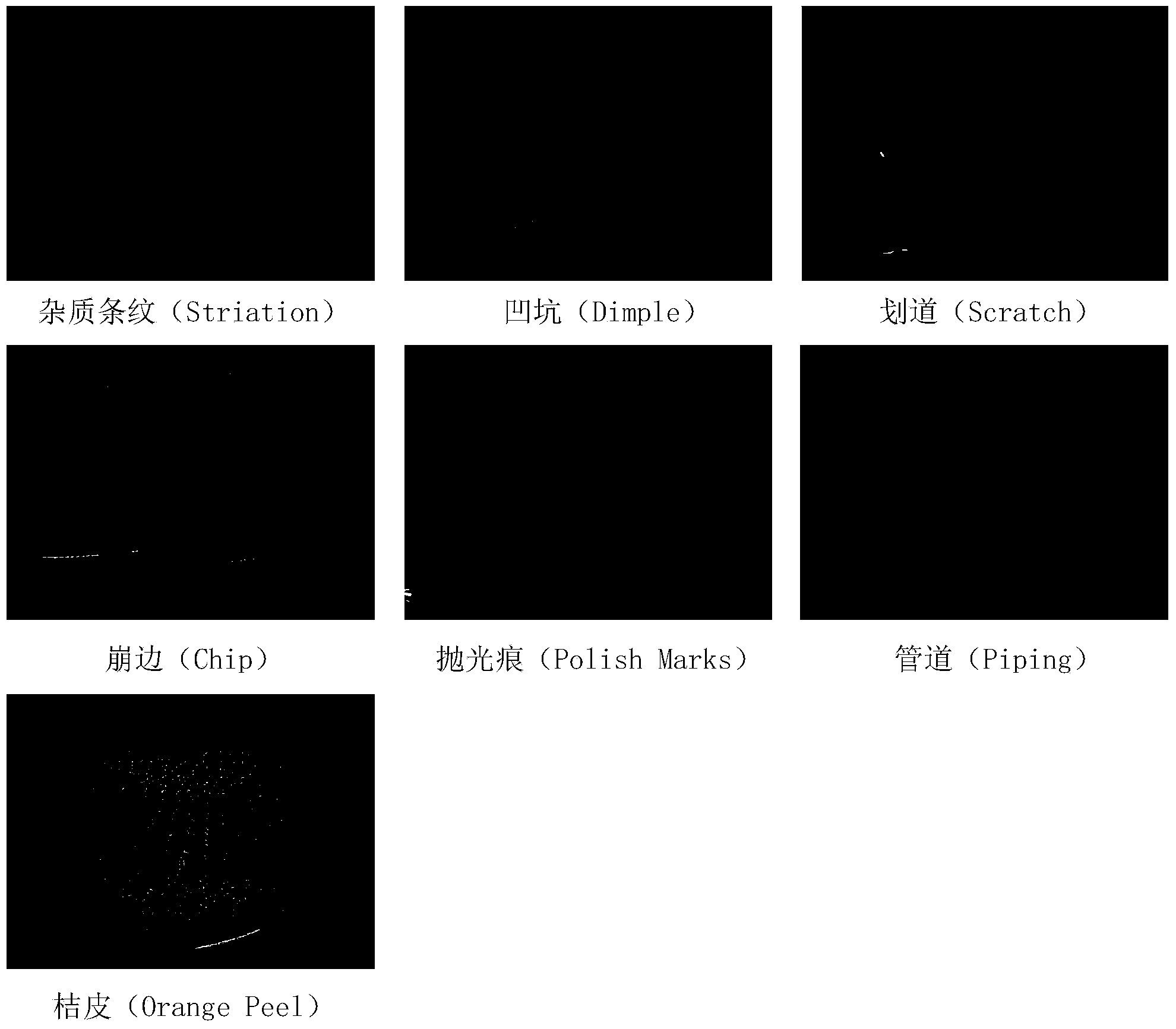

Method for detecting defects of 8-inch polished wafers through light-transmitting mirror

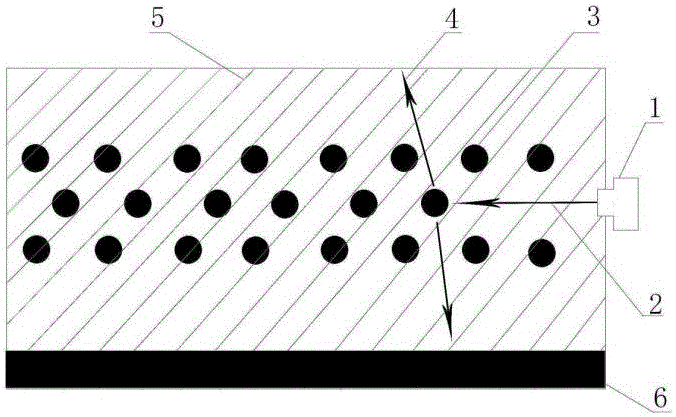

InactiveCN104316542AOn-line control of preparation qualityHigh sensitivityOptically investigating flaws/contaminationSurface structureStructural property

The invention provides a method for detecting the defects of 8-inch polished wafers through a light-transmitting mirror, wherein in the method, the defects of the 8-inch polished wafers are detected through the light-transmitting mirror. By means of the method, the surface structural properties of the large-area silicon wafers are detected without damage in real time through the light-transmitting mirror, the map of the poor defects of the various silicon wafers is obtained through summarization, and the quality of the monocrystalline silicon wafers is monitored on line.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

LED down lamp

InactiveCN105757528AReasonable structural designLight materialPoint-like light sourceLighting heating/cooling arrangementsEngineeringAluminum substrate

The invention relates to an LED down lamp. The LED down lamp comprises a lamp body, a light transmitting mirror, a reflection lampshade, an LED light, an aluminum substrate and a driving power supply, wherein the light transmitting mirror, the reflection lampshade and the driving power supply are mounted on the lamp body; the LED light is mounted on the aluminum substrate; the aluminum substrate is mounted in the lamp body; the lamp body is made of aluminum and is processed through spinning, and the bottom surface of the lamp body extends outwards to form a wing plate for heat dissipation; an opening of the lamp body is horn-shaped, light transmitting mirror bulges are arranged outwards on the periphery of the light transmitting mirror, and a lamp body groove matched with the light transmitting mirror bulges is formed in the lamp body. The LED down lamp is reasonable in design, materials are saved, the cost is reduced, the production efficiency is improved, the heat dissipation is faster, the heat dissipation effect is better, and the service life of the LED down lamp is prolonged; furthermore, the processing procedure is reduced, installation and maintenance are more convenient, the anti-dazzling effect of the lamp is better, the visual effect is softer and more even, the harm to eyesight of a human body due to glare is prevented, and accordingly, the vision and the eyesight of the human body are protected very well.

Owner:高卫军

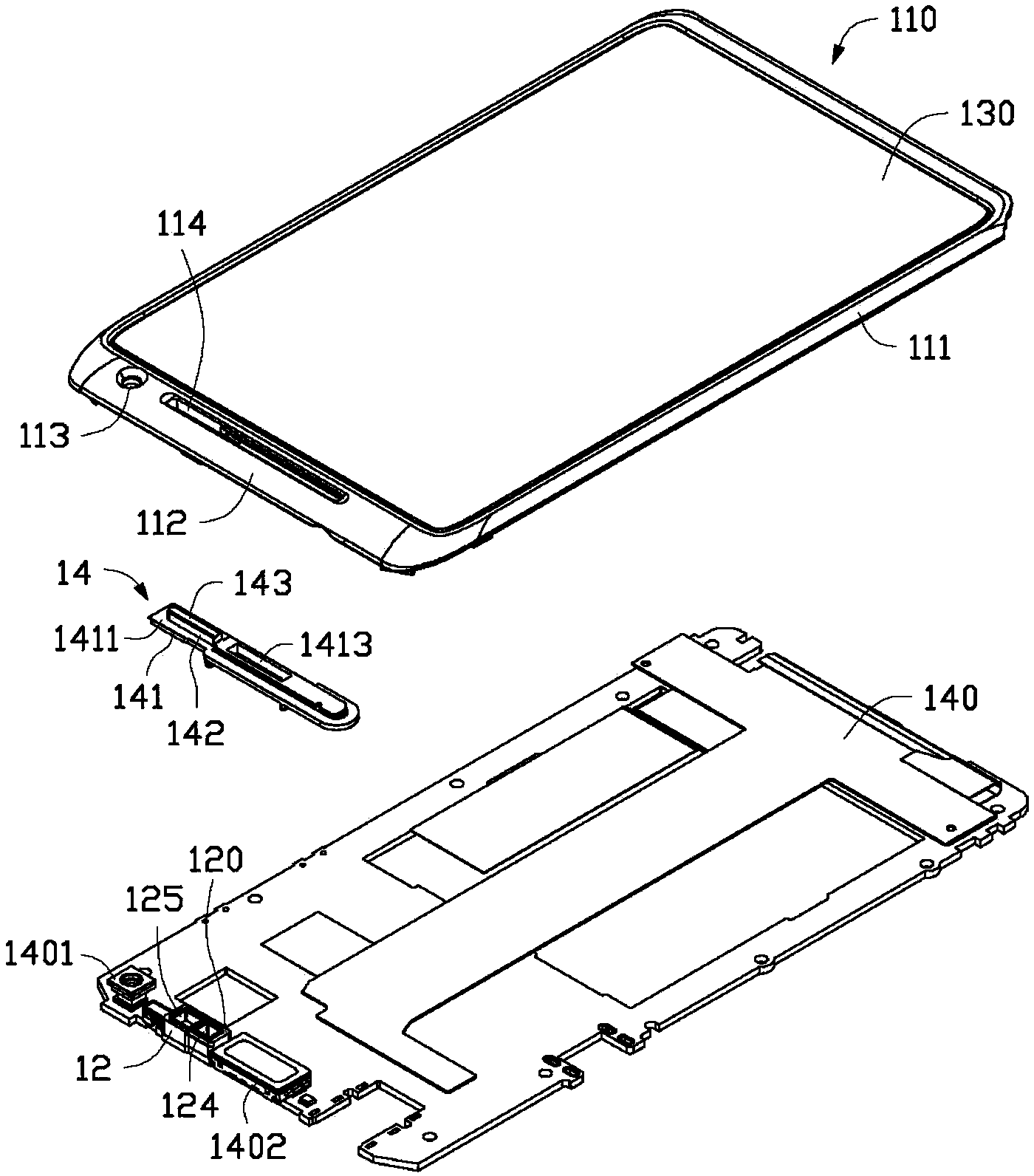

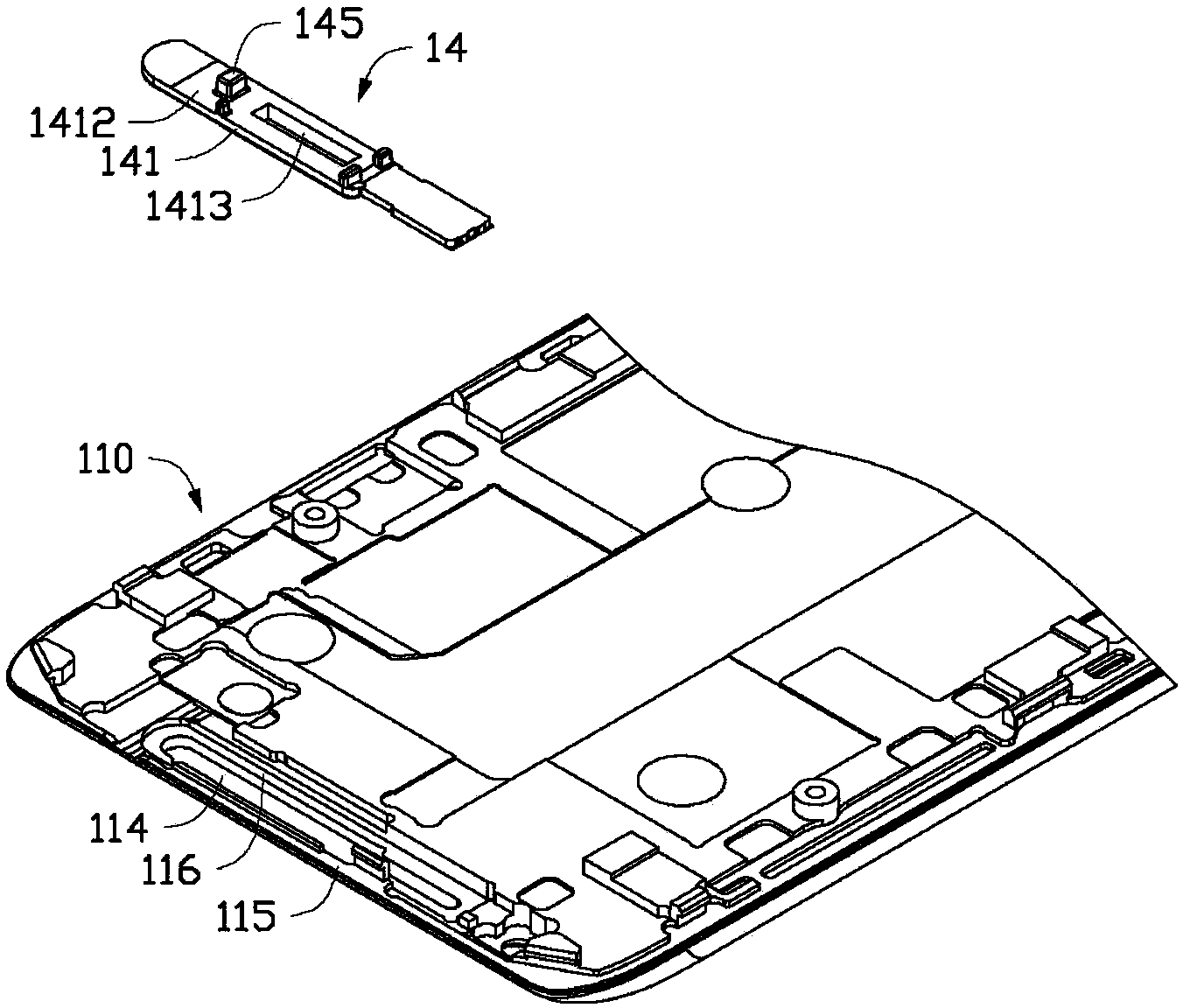

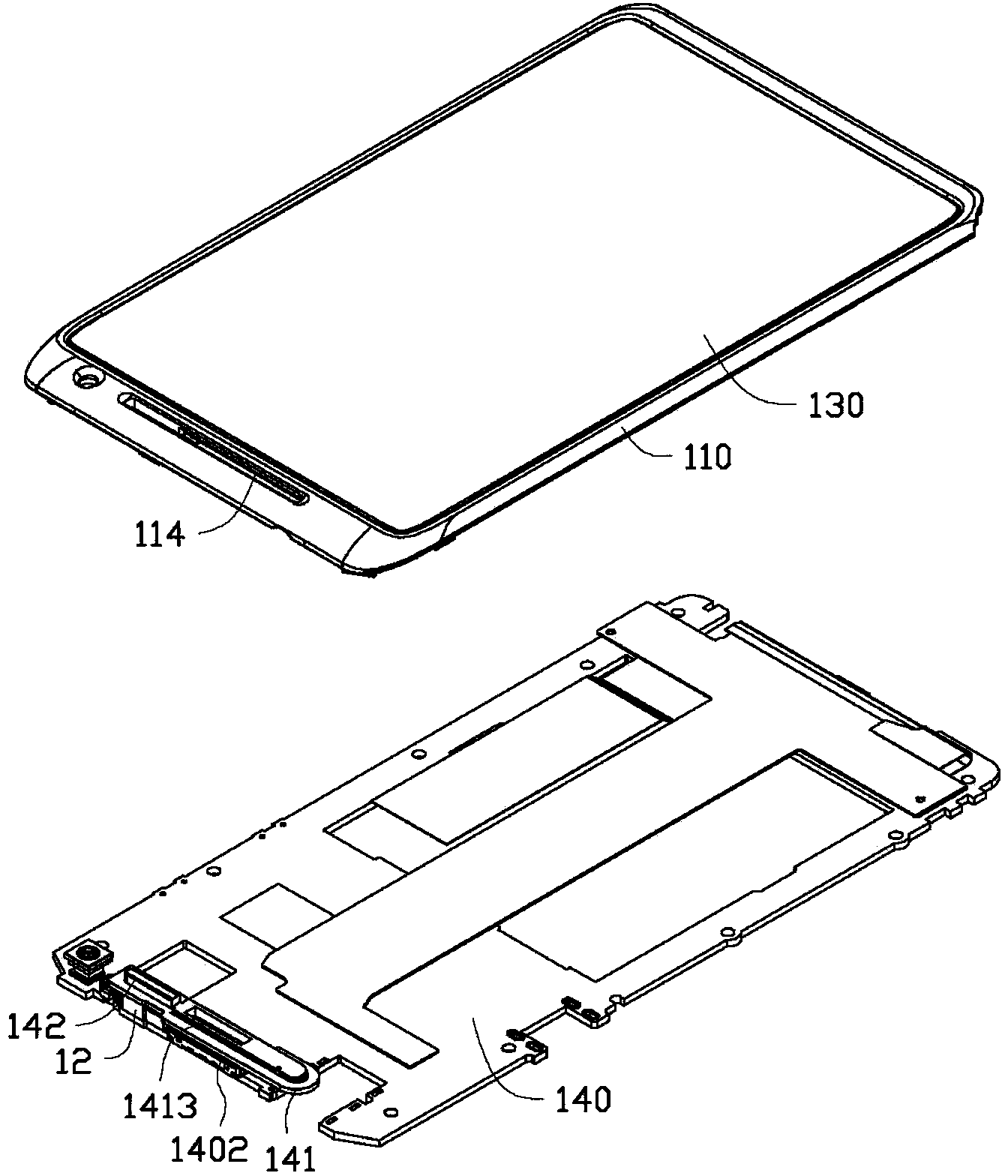

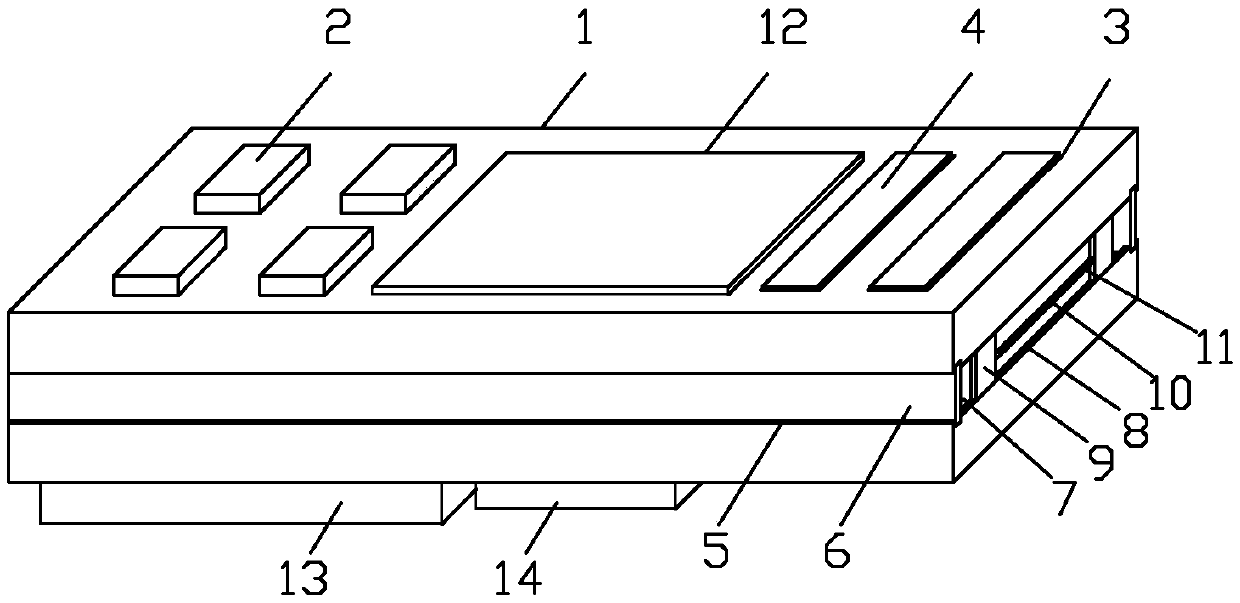

Sensing device and electronic device with same

The invention relates to a sensing device. The sensing device comprises an installing body, a light source and a sensor. The installing body is provided with a light outlet and a light inlet adjacent to the light outlet. The light source and the sensor are adjacently arranged in the installing body and are opposite to the light outlet and the light inlet respectively. The sensing device further comprises a light-transmitting plate made of a polycarbonate material. The light-transmitting plate comprises a substrate and a light-transmitting mirror arranged at one end of the substrate in a protruding mode. The light-transmitting mirror is provided with a light outlet surface which is an oblique plane. When the light-transmitting plate is arranged on the installing body, the light-transmitting mirror is opposite to the light outlet and the light inlet, and light of the light source is output through the light outlet surface. The invention further relates to an electronic device with the sensing device.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Focus lamp capable of generating rectangular light spots by single lens

InactiveCN102767765AConcentratedReduce light lossRefractorsFixed installationOptoelectronicsBrightness perception

The invention discloses a focus lamp capable of generating rectangular light spots by a single lens, comprising a light source. The focus lamp is characterized in that a cylindrical light-transmitting lens is arranged at the front part of the light source; and the cylindrical light-transmitting lens is used for collecting scattered light sent by the light source and enabling light spots which are formed by illuminating an illuminated object by the light sent by the light source to be the rectangular light spots. The focus lamp of the rectangular light spots has the characteristics of wide application range, intensive light collection, high brightness and less light loss. Furthermore, the focus lamp is convenient to manufacture and low in cost, so that the focus lamp is suitable for wide popularization.

Owner:DALIAN XINQIHUI TECH

Rotating type spotlight

InactiveCN107504407ASimple structureReasonable designLighting support devicesLighting heating/cooling arrangementsFixed frameCooling effect

A rotary spotlight involved in the present invention includes a shell, the shell is circular with openings up and down, the bottom of the shell is screwed and connected to a clamping shell, and the inner wall of the clamping shell is provided with a high-definition light-transmitting mirror. The inner wall of the housing is sequentially provided with a circuit board, a circuit channel and a light source from top to bottom, the circuit board and the light source are connected through the circuit channel, a heat sink and a dust cover are provided on the top of the housing, and the The heat sink is arranged in the inner cavity of the dustproof cover, and one side of the shell is symmetrically provided with a cylindrical fixing frame, and one side of the cylindrical fixing frame is provided with a first rotating bracket, and one side of the first rotating bracket is symmetrical There is a first rotating bracket interface, and the first rotating bracket interface is set at the connection between the first rotating bracket and the cylindrical fixed frame. The structure is simple, the design is reasonable, and the adjustment angle of the lamp is increased so that the lamp can Good lighting effect can be achieved in the environment, and the heat dissipation effect is better.

Owner:RUGAO LANTU KNITTING CLOTHING CO LTD

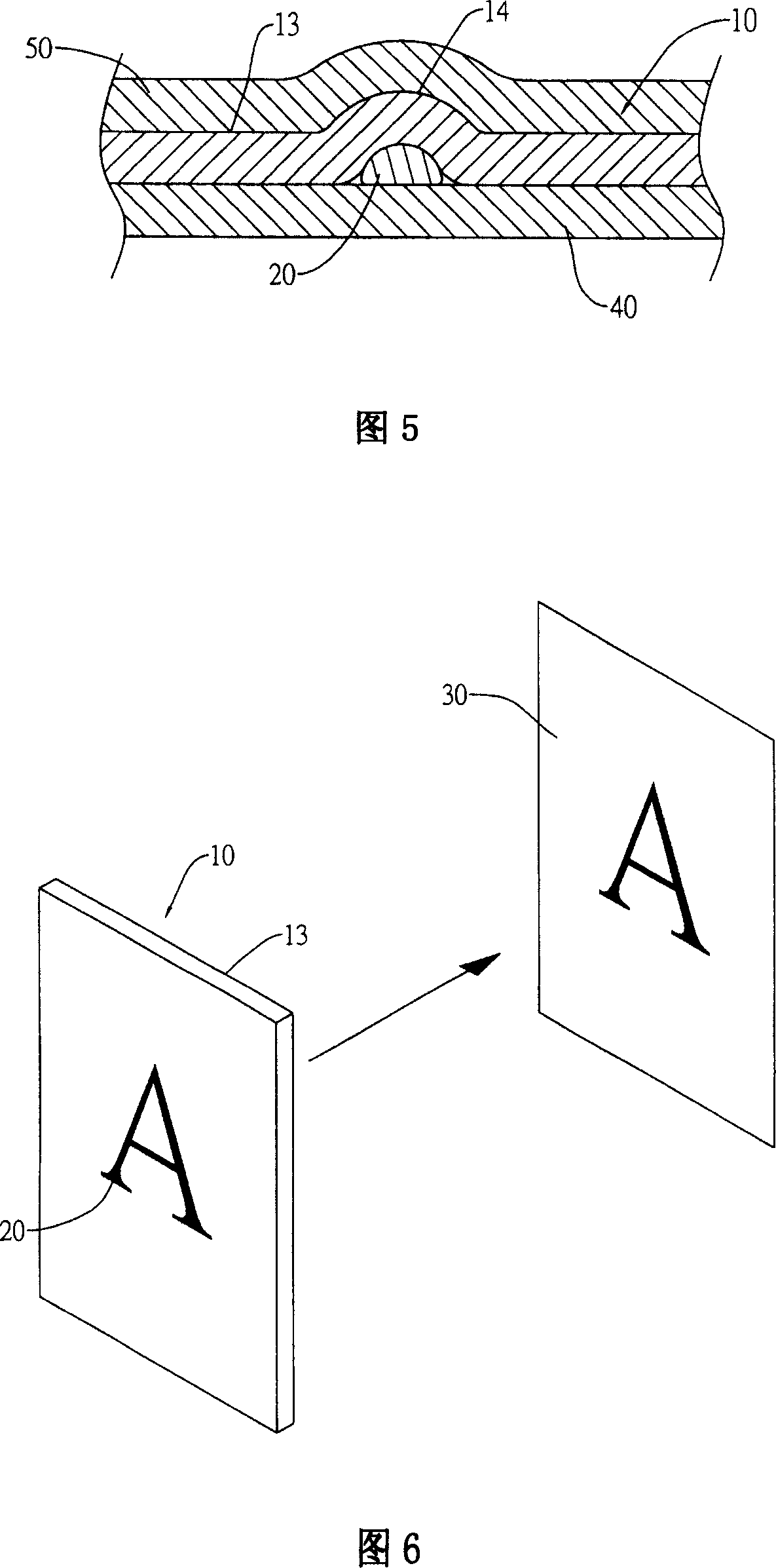

Magic mirror manufacturing method and its structure

InactiveCN101025453AFast preparationSimple structureMirrorsLight effect designsTransmittanceMaterials science

The invention relates to a manufacturing method of translucent glass, it includes a reflector forming step, a ornamentation plot step and a freezing step; the reflector forming step is that to form a reflector on the one side of a mirror; the ornamentation drafting step is that to coat solidification shrinkage glue on the other side of the relatively reflector of the mirror to plot ornamentation; the freezing step is that glue solidification shrinkage led to the volume changed, after the glue is solidified ,there will produce a change of curvature in the relatively glue place of the reflector, the setup of glue is fast and simple, and use glue solidification shrinkage characteristics, produce a change of curvature on the surface of mirror, so it can reflect light, project ornamentation image, and due to no need to Laser treatment forever to mirror, also no need to polishing handling in mirror after the ornamentation formed, the invention not only eliminates process time and can increase transmittance of translucent glass.

Owner:MUYING SCI & TECH

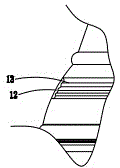

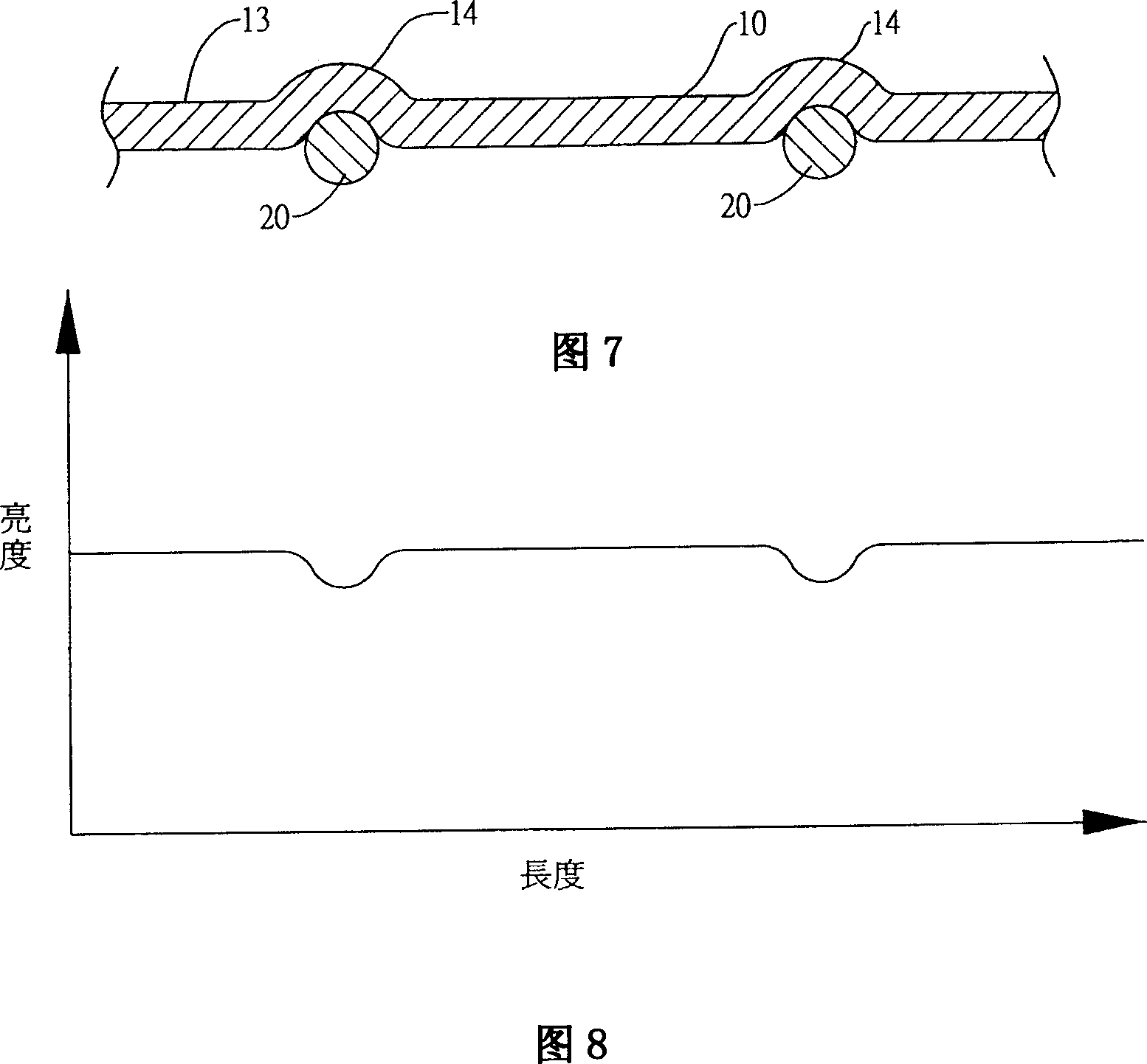

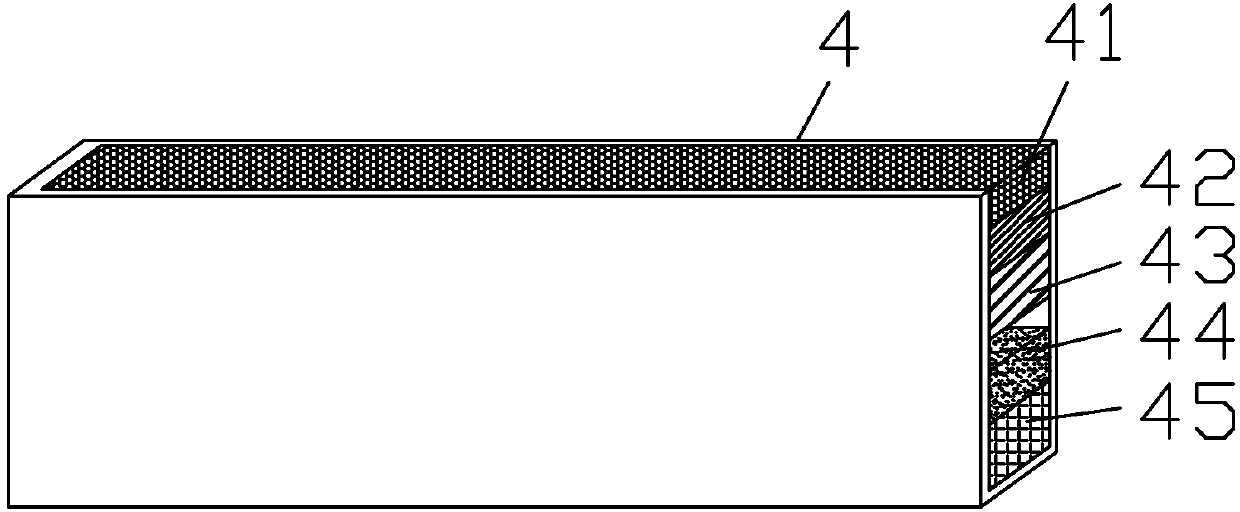

Lamp strip system capable of achieving large-area uniform light-emitting function

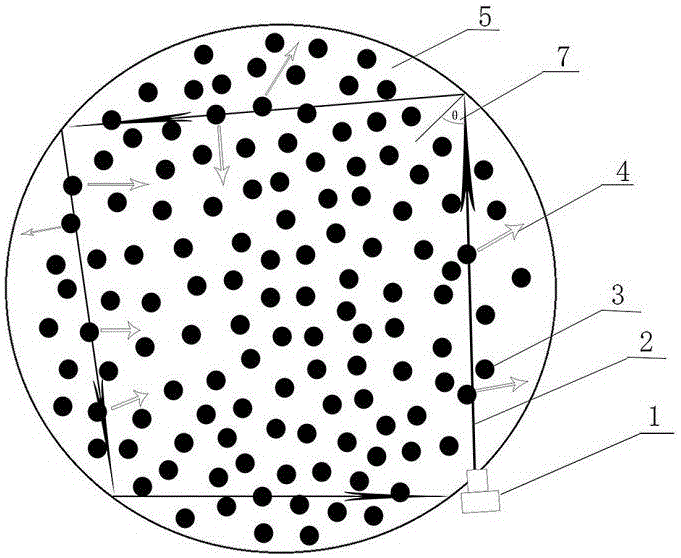

PendingCN110230801AImprove uniformityExpand the radiation rangeOptical signallingRoad vehiclesLight guideOptoelectronics

The invention provides a lamp strip system capable of achieving the large-area uniform light-emitting function. The lamp strip system comprises a light guide strip, a reflector and an inner light-transmitting mirror. The light guide strip is positioned between the reflector and the inner light-transmitting mirror. The light guide strip is provided with two sections of toothed optical patterns, namely an optical pattern I and an optical pattern II. By designing the light guide strip with the tooth-shaped optical patterns in multiple directions, the light guide strip not only can be used for punching bright patterns in front of the light guide and ensuring uniformity, but also can be used for punching side edges or large-visual-angle patterns. Therefore, the uniformity of a whole optical system is ensured. Tooth-shaped optical patterns and orientations of the tooth-shaped optical patterns on the light guide strip are additionally designed. Through diffuse reflection of the reflector andthe inner light distribution mirror made of the emulsifying material, the single light guide strip is formed. The irradiation range is wide, and the lighting effect is uniform. The consistent and goodlight-emitting effect can be kept at all angles. The LED lamp has the advantages of being small in number of LED light sources, low in cost and uniform in light-emitting.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

Heat-insulating light-penetrating device

ActiveCN102252625AEasy to passReduce the impactUsing optical meansOptoelectronicsMeasuring equipment

The invention belongs to the field of optical diameter measuring, and particularly relates to a heat-insulating light-penetrating device for an optical diameter measurer. The profile of the heat-insulating light-penetrating device is of a pipe sleeve shape; heat-insulating light-penetrating lenses which can be radially transmitted by a measuring light ray are symmetrically arranged on a pipe wallof the pipe sleeve along a light ray to be measured and a bar material axis line; and mirrors of the heat-insulating light-penetrating lenses are mutually parallel and are parallel to an advancing direction of the light ray to be measured and the bar material axis line. According to the invention, the influence on measuring equipment, caused by a working complex environment of the measuring equipment, can greatly lower without influencing passing of a measuring optical path, thereby the measuring accuracy of the optical diameter measurer for which the heat-insulating light-penetrating device is suitable is enhanced.

Owner:HEFEI BAISHENG SCI & TECH

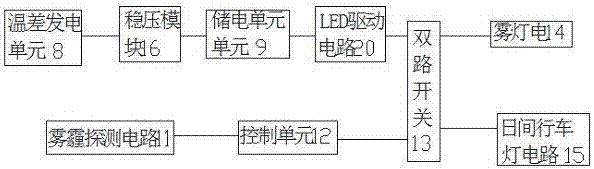

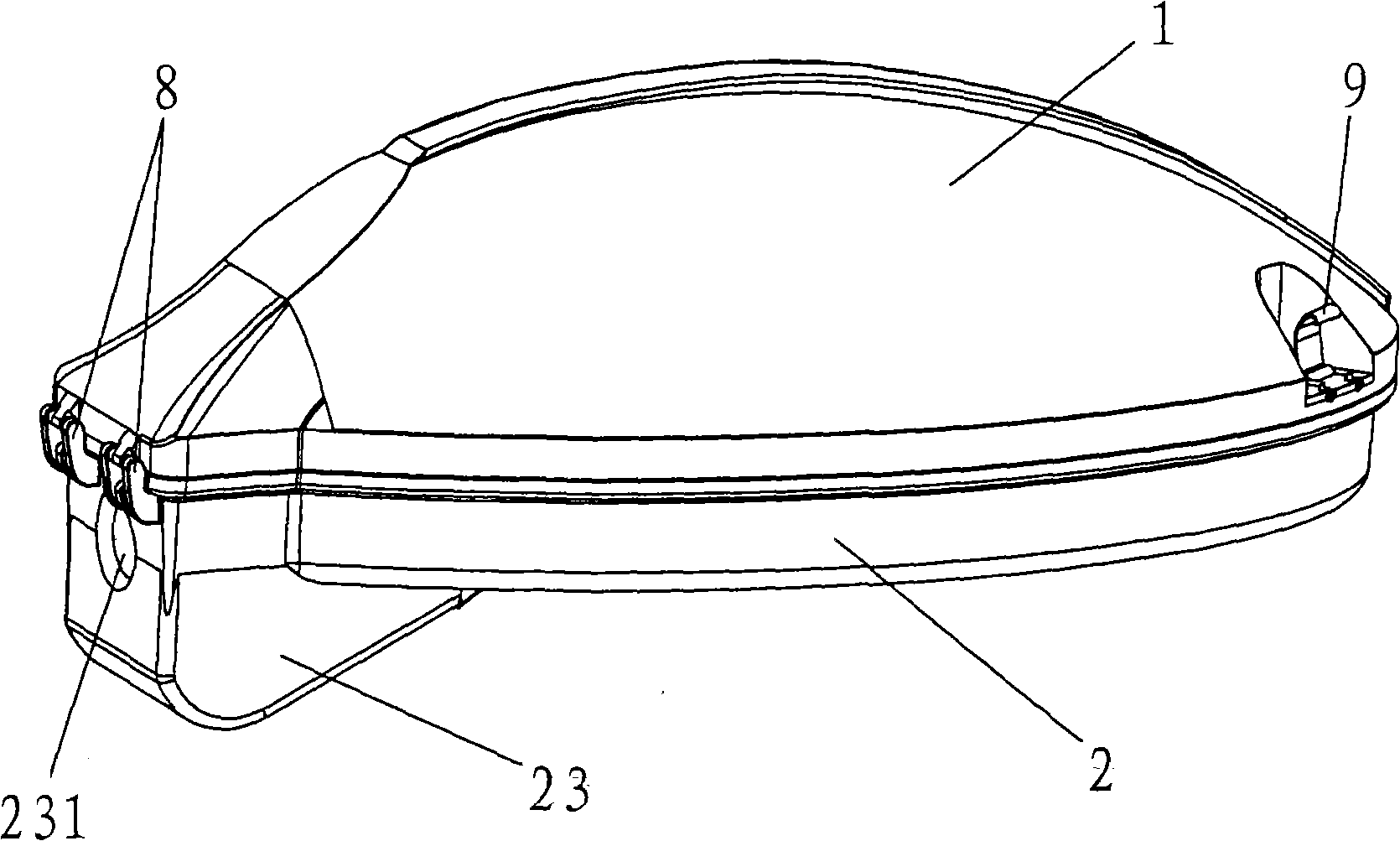

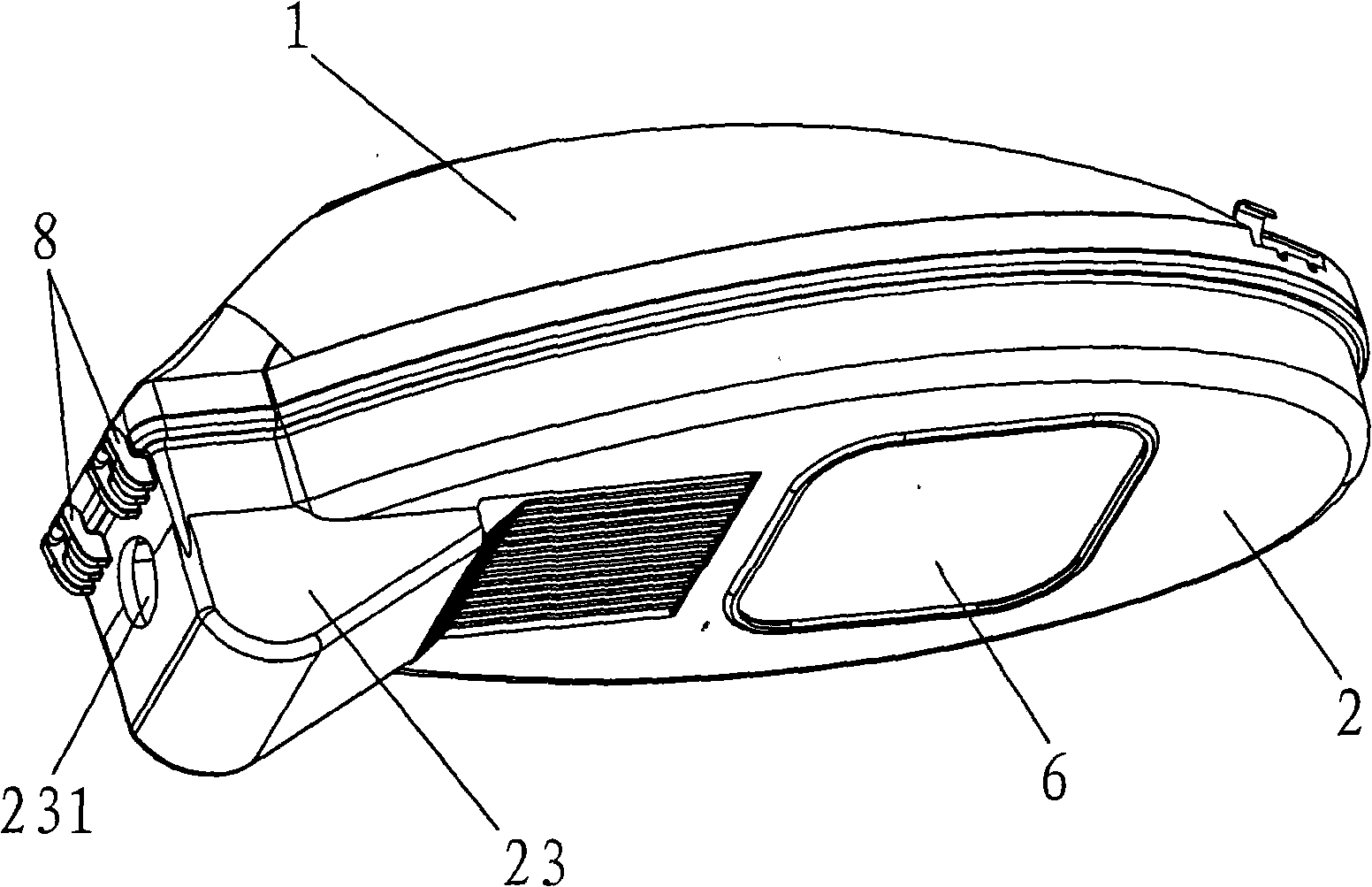

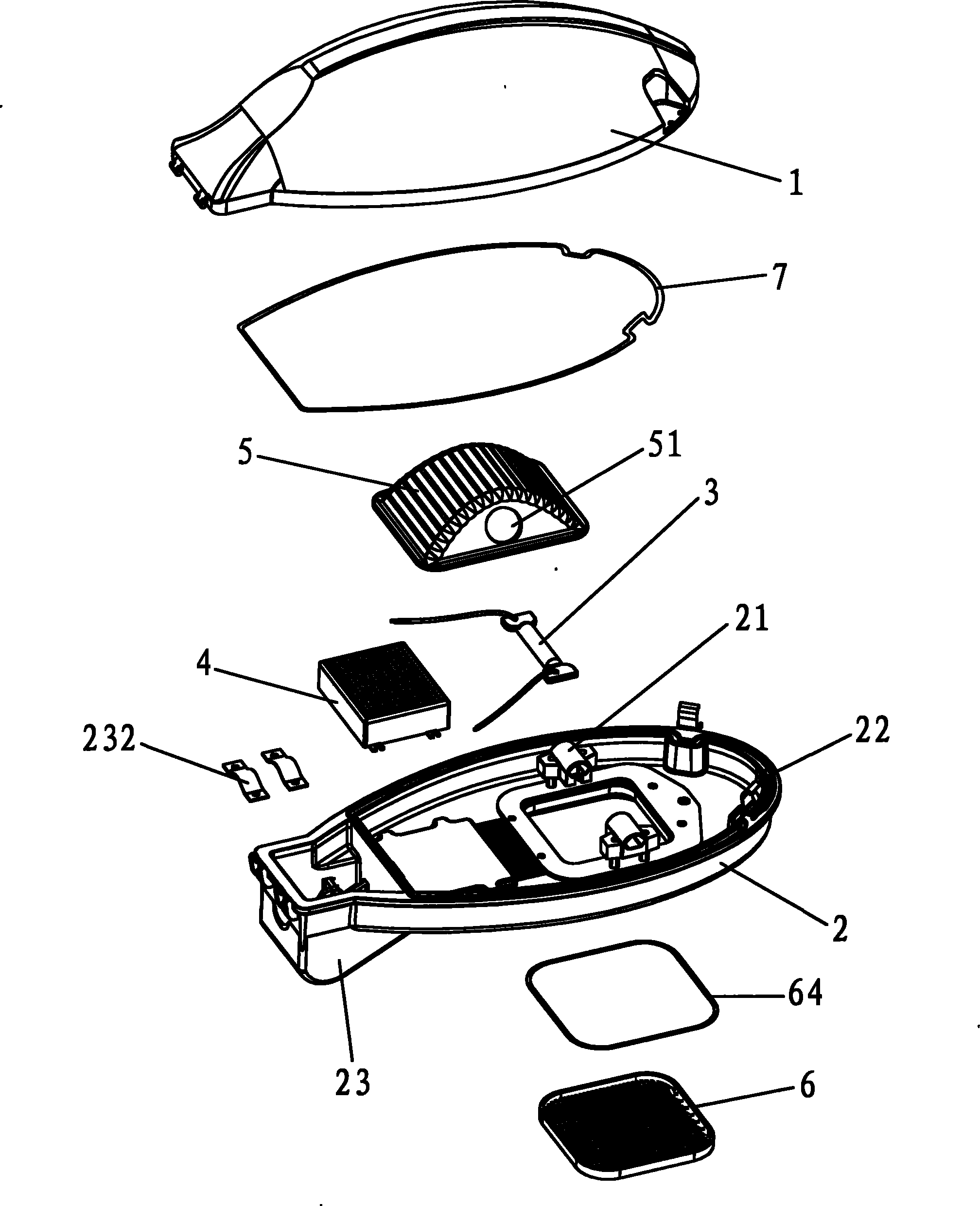

Dual-function automotive lamp

InactiveCN107339659AAvoid wastingTake advantage ofElectric circuit arrangementsLighting heating/cooling arrangementsElectricityEngineering

The invention belongs to the field of automobile spare parts, and particularly relates to a dual-function automotive lamp. The dual-function automotive lamp comprises a main body shell and a light transmitting mirror which are fixed to define a cavity. A lamp holder is arranged in the cavity. LED daytime running lamp beads, an LED fog lamp bead and reflection cups are arranged on the lamp holder. The lamp holder is further fixedly connected with an LED heat dissipation aluminum plate. The automotive lamp further comprises a haze detection circuit, a control unit, a two-way switch, a heat collector, an electricity storage unit and a thermoelectric power generation unit. The two-way switch controls the LED daytime running lamp beads and the LED fog lamp bead to be lighted up alternately. The haze detection circuit can detect the haze concentration in the air and further controls the two-way switch to turn on the LED fog lamp bead through the control unit. The dual-function automotive lamp has the dual functions of a fog lamp and a daytime running lamp, and the lamps can be intelligently controlled to be switched on and off. In addition, by means of the dual-function automotive lamp, collected heat energy can be converted into electric energy to be directly used by the automotive lamp.

Owner:南宁燎旺车灯股份有限公司

Energy-saving road lamp

InactiveCN101463965BImprove light utilizationImprove antioxidant capacityElectrical apparatusElectric lighting sourcesEffect lightEngineering

The invention relates to street lamp technology field, in particular to an energy-saving street lamp, which comprises an upper cover, a lower cover, a lighting tube, an electronic ballast providing power for the lighting tube and a reflecting shade, wherein the upper cover snaps with the lower cover, the lighting tube locates between the upper cover and the lower cover, the reflecting shade is fixed between the lighting tube and the upper cover, the lower cover is equipped with a transmitting filter corresponding to the lighting tube, and the reflecting shade is equipped with a through hole for the placement of the lighting tube; the reflecting shade comprises an outer protective layer, a nanometer glistening layer and an inner protective layer, wherein the nanometer glistening layer is sprayed on the undersurface of the outer protective layer, the inner protective layer is sprayed on the undersurface of the nanometer glistening layer; as the nanometer glistening layer possesses a favorable reflection rate, namely, a higher reflection rate for visible light, and the nanometer glistening layer also possesses a favorable inoxidability, thus the weakening of the reflection rate can slow down, and the layer still possesses favorable reflection effects even though the layer services a long time, thus compared with the traditional lamp, the energy-saving street lamp of the inventionconsumes less electric power and possesses a longer service life.

Owner:东莞市宝利节能有限公司

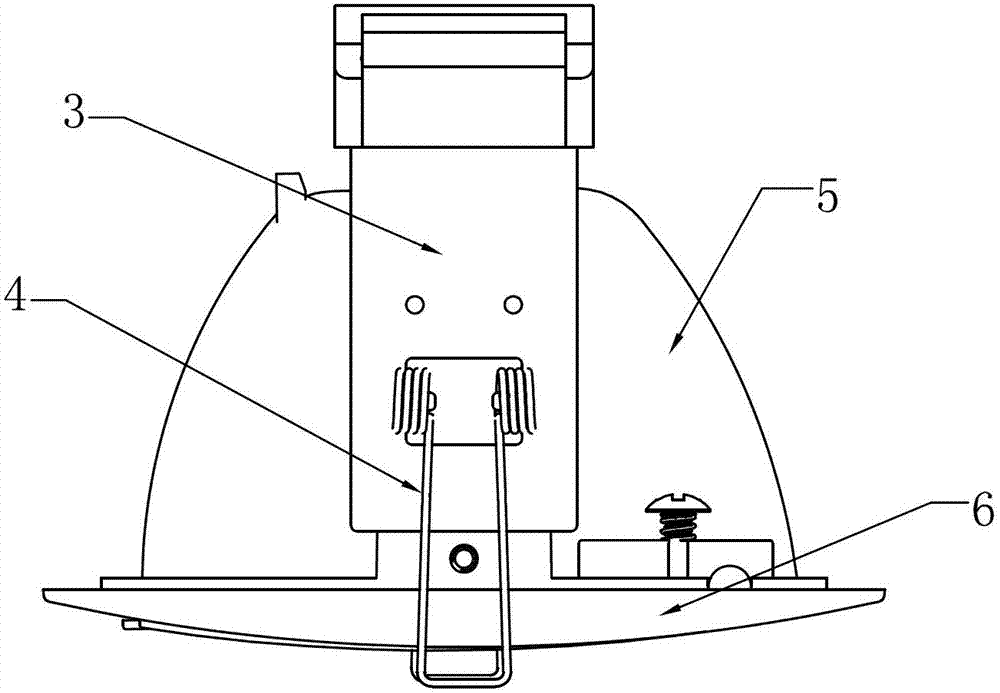

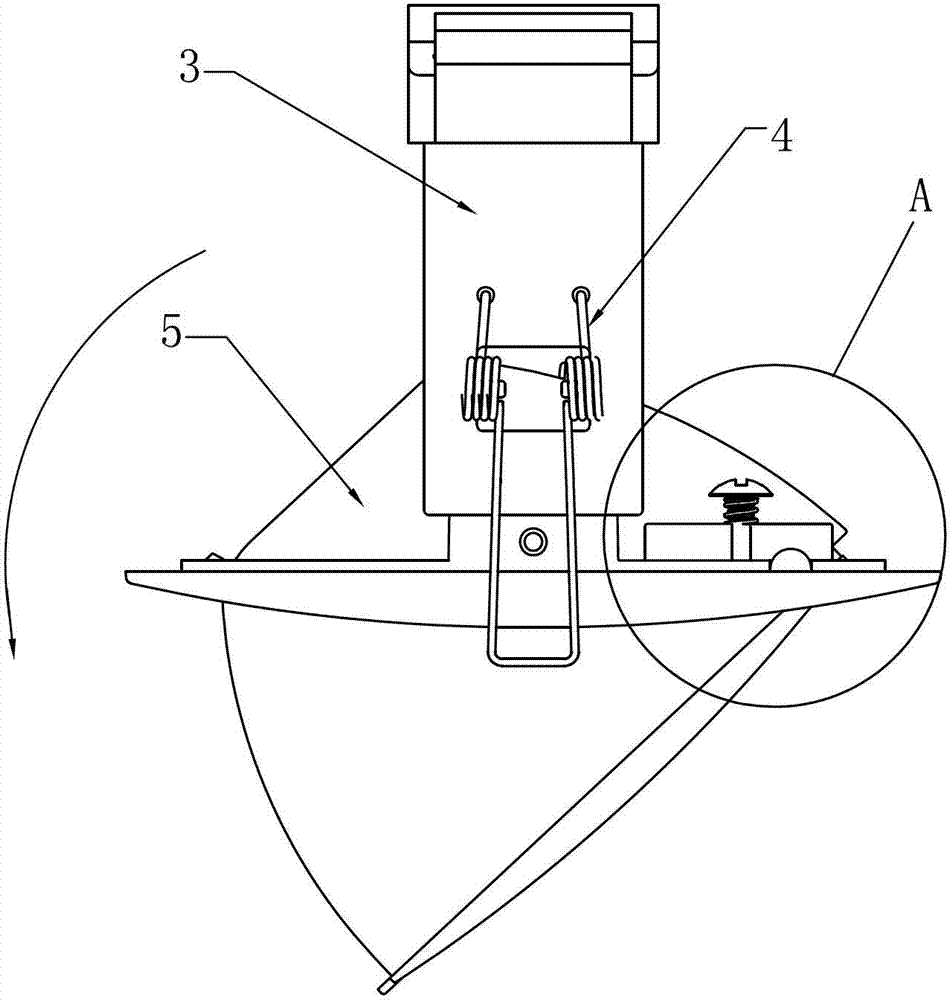

Light emitting diode (LED) lamp with adjustable irradiation angles

ActiveCN102767729ASolve the problem of illumination angleImprove reflection efficiencyLighting support devicesPoint-like light sourceEngineeringIrradiation

The invention discloses a light emitting diode (LED) lamp with adjustable irradiation angles. The LED lamp comprises a power line, a driving circuit module, a supporting frame, a snap spring, a lamp body and a lamp holder, wherein the power line and the driving circuit module are arranged on the supporting frame and are connected, the driving circuit module is connected with the lamp body, the lamp body is connected with the lamp holder, the lamp body comprises a lamp casing, a lamp cover, a reflecting shade and an LED irradiation module, the lamp casing and the lamp cover are assembled to form a first cavity, the reflecting shade is arranged inside the first cavity, the LED irradiation module is arranged on the reflecting shade, the reflecting shade is covered by a transmitting filter, the supporting frame is arranged on the lamp holder, the lamp body is hung on the lamp holder thorough the snap spring, two sides of the lamp body are provided with column-shaped bumps, two sides of the lamp holder are provided with semicircular grooves, the column-shaped bumps and the semicircular grooves are matched, and the matching portions of the column-shaped bumps and the semicircular grooves are pressed by pressing blocks. The lamp body rotates, then the LED irradiation module is driven to rotate, irradiation angles are changed, the problem of the irradiation angles of the LED lamp is effectively solved.

Owner:NINGBO YUSING OPTOELECTRONIC TECH CO LTD

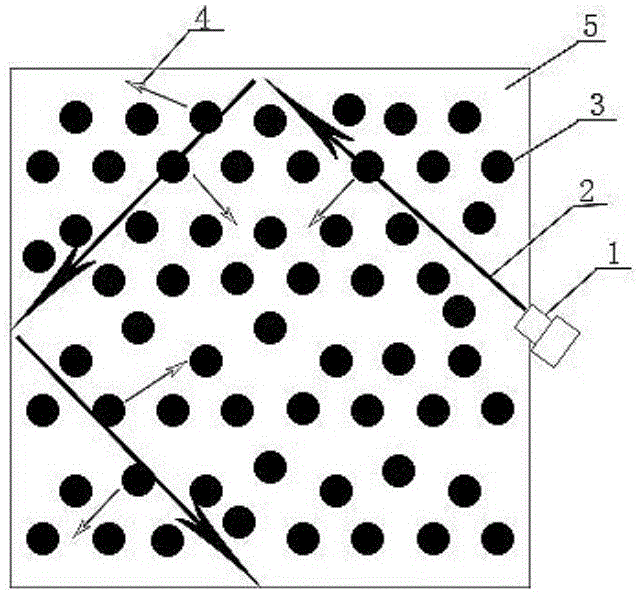

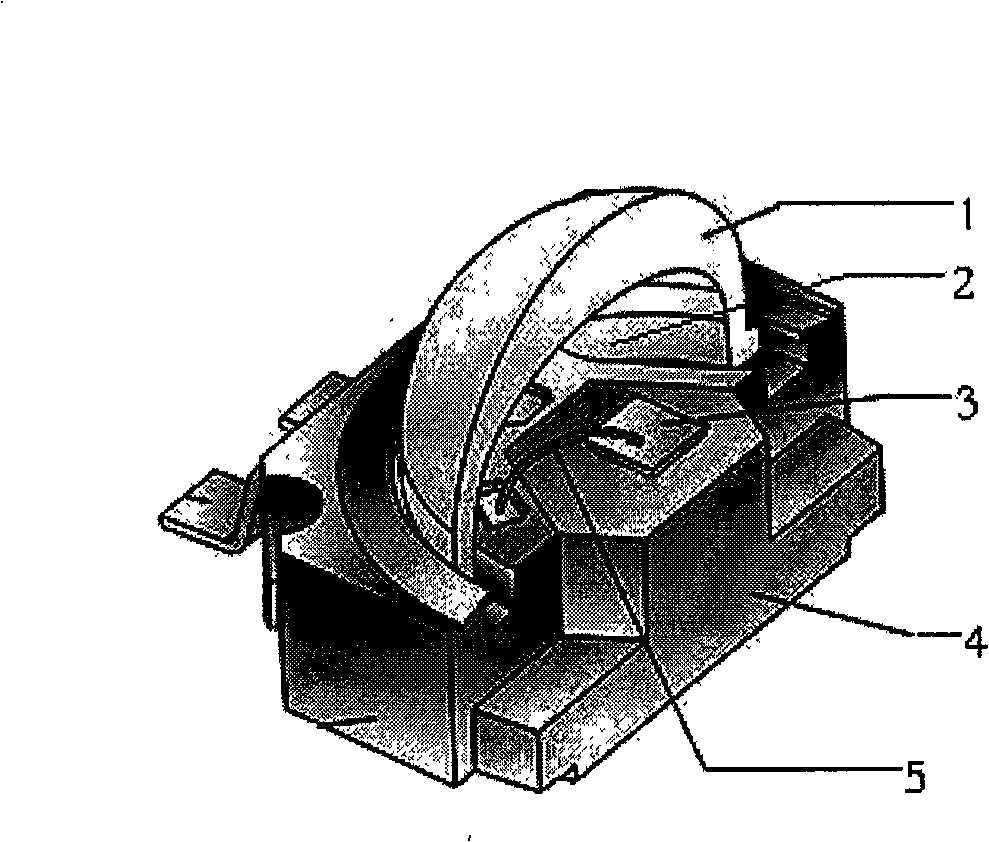

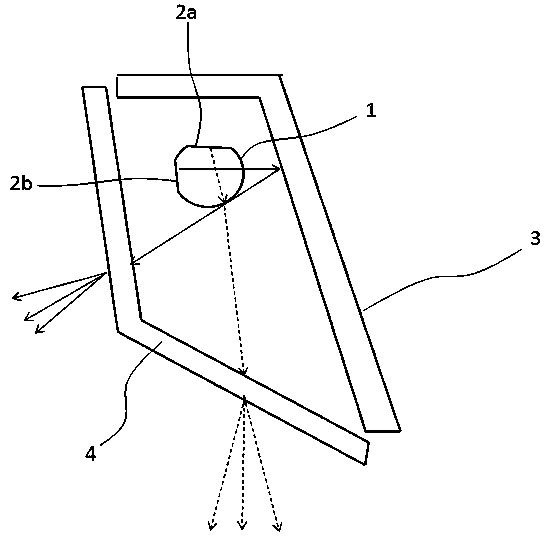

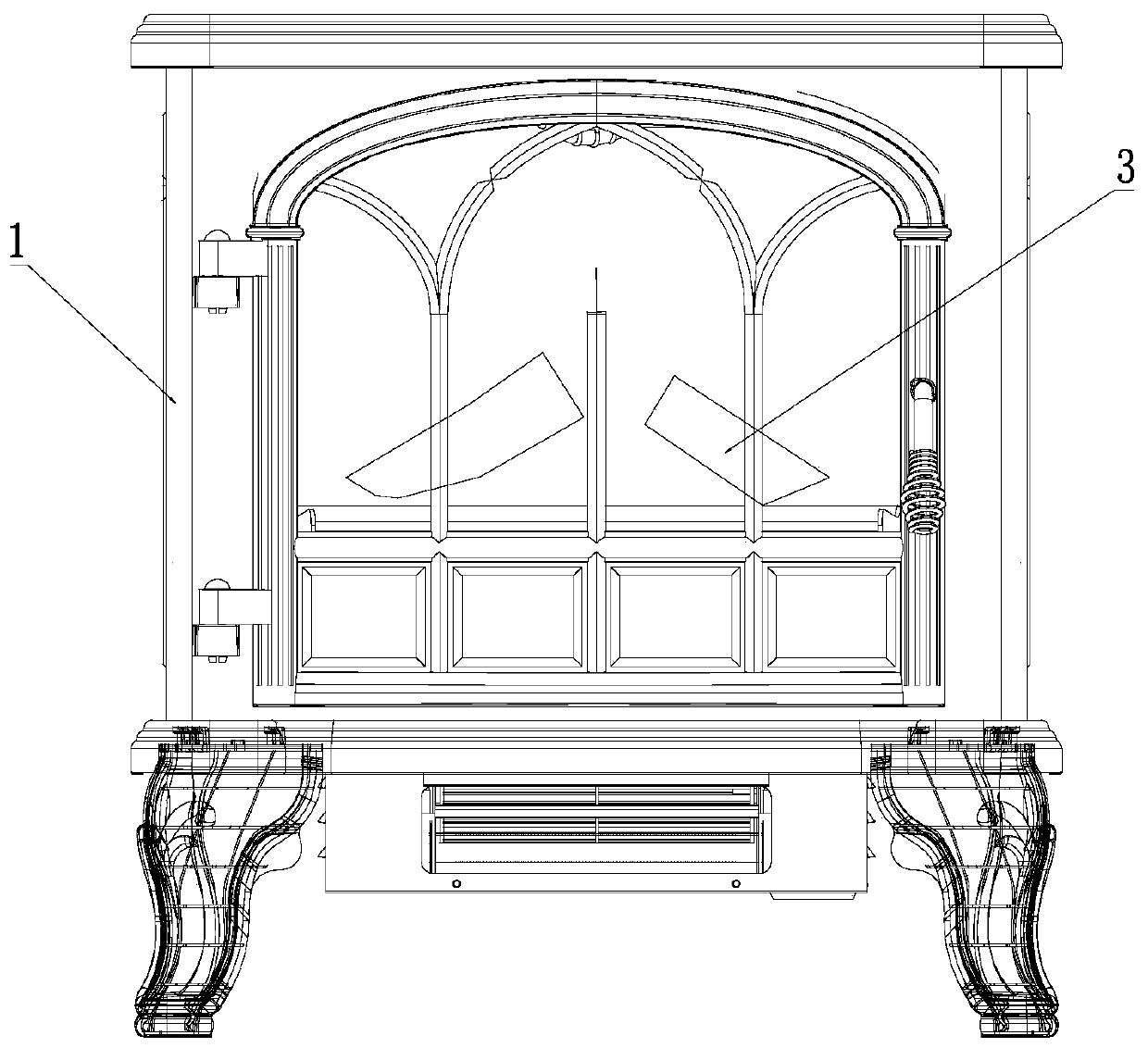

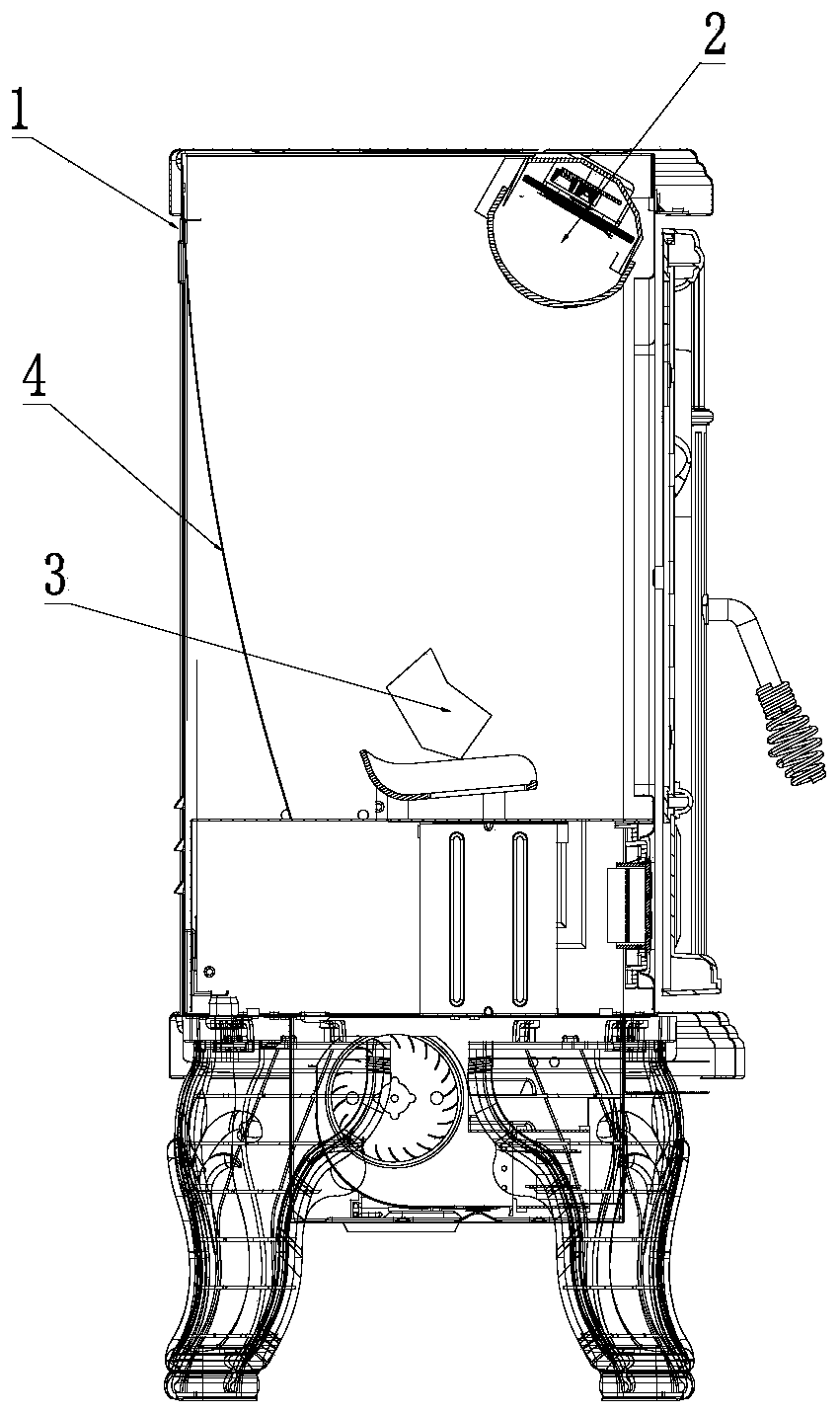

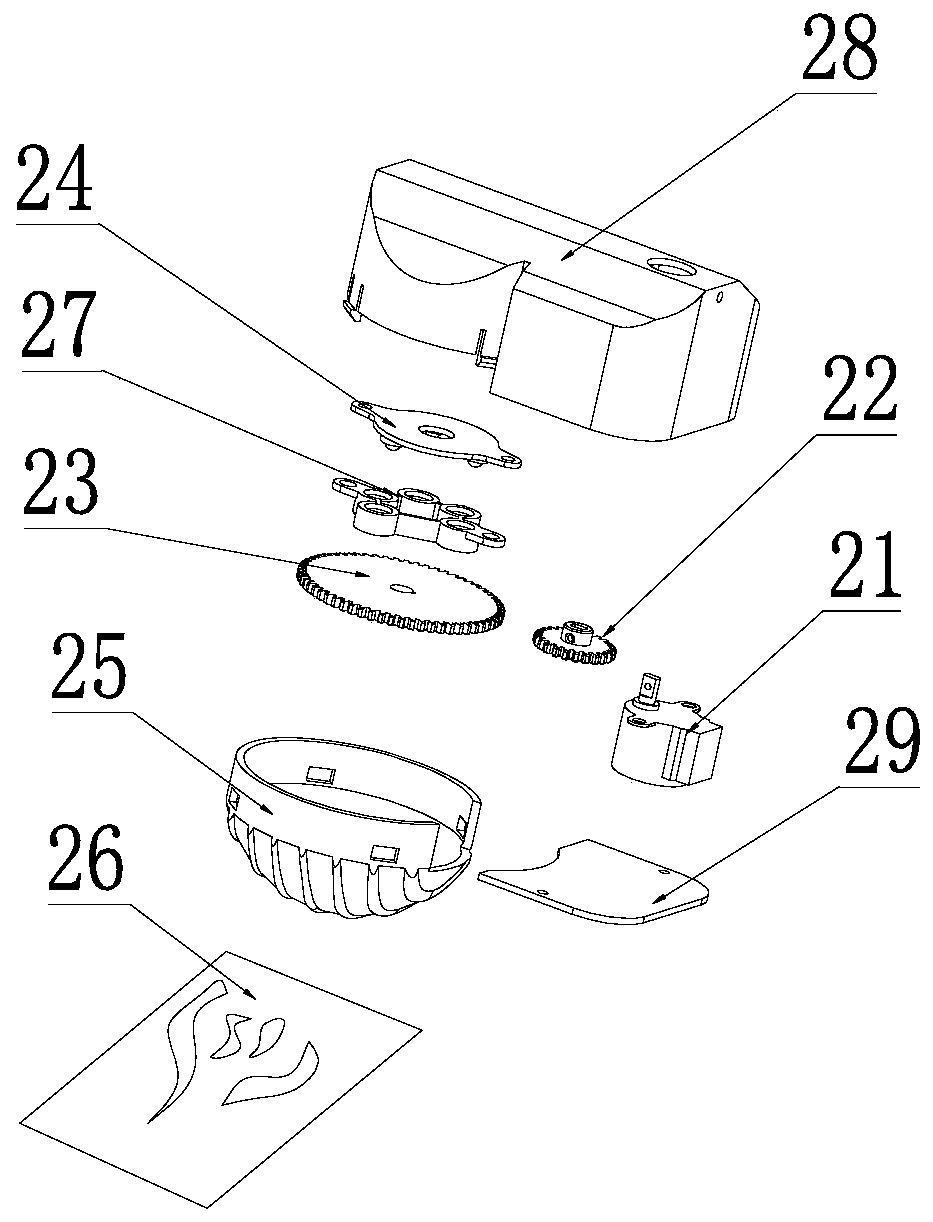

3D flame simulation system and electric fireplace

PendingCN109973913AHigh simulationCompact structureElectric heating systemElectric lightingElectricityLED lamp

The invention relates to the technical field of electric fireplaces, in particular to a 3D flame simulation system and an electric fireplace. The 3D flame simulation system comprises a projection backboard, simulated charcoal and a light source projection device. The light source projection device comprises an LED lamp panel, a driver, a corrugated transparent cover and a light transmitting mirror. According to the invention, light rays are reflected to the projection backboard without using parts such as reflective strips or electroplated reflective sheets. Instead, the driver is adopted to drive the light transmitting mirror to rotate. Therefore, light rays, which penetrate through the corrugated transparent cover, are projected to the projection backboard and the simulated charcoal, sothat the moving 3D flame shape is formed. The flame jumping effect is achieved, so that 3D flame simulation effect is more realistic. In addition, the light source projection device is simple and compact in overall structure, small in size and capable of being independently used in an electric fireplace of any size. As a result, the assembly efficiency of the electric fireplace is higher, and thethickness of the electric fireplace can be made thinner.

Owner:NINGBO SINGFUN ELECTRIC APPLIANCE

Switch controller with night vision effect for indoor lamp

ActiveCN107676752AImprove creativityAchieve lighting effectsElectric circuit arrangementsLuminescenceNight visionFluorescence

The invention discloses a switch controller with a night vision effect for an indoor lamp. The switch controller comprises a shell; keys are fixedly arranged on one side of the upper surface of the shell in a sleeved mode; sleeve grooves are formed in the side, far away from the keys, of the upper surface of the shell, and noctilucent bodies are fixedly arranged in the sleeve grooves in a sleevedmode; the noctilucent bodies each comprise a light-transmitting mirror, wherein the bottom end of the light-transmitting mirror is fixedly provided with an enoscope, a collecting lens is fixedly arranged at the bottom end of the enoscope, a fluorescent layer is laid below the collecting lens, and a shading layer is fixedly arranged at the bottom end of the fluorescent layer; a fixing groove is formed in the front face of the shell, and a glass plate is fixedly arranged on the front face of the fixing groove in a sleeved mode; and the back surface of the glass plate is fixedly provided with fluorescent sheets positioned in the fixing groove, and the side faces of the fluorescent sheets are movably connected with the side faces of driven blocks which are movably arranged on a sliding groovein a sleeved mode. According to the switch controller, the noctilucent bodies are arranged to absorb light to achieve a lighting effect, the fluorescent sheets are arranged for night illumination, sothat searching is convenient during use, the identification degree is high, and therefore practicability of the switch controller is improved.

Owner:浙江松日电气有限公司

LED (Light Emitting Diode) ball lamp

InactiveCN102734670ASimple structureSafe and reliable structurePoint-like light sourceLighting heating/cooling arrangementsEngineeringAluminum substrate

An LED (Light Emitting Diode) ball lamp comprises a rubber housing, an aluminum substrate, an LED lamp bead and a ball glass bulb, wherein a transparent light-transmitting lens which can refract and reflect light emitted by the LED lamp bead for many times and has an irregular shape is arranged on one side of the aluminum substrate, corresponding to the LED lamp bead. According to the invention, the structure that the transparent light-transmitting lens with the irregular shape is additionally arranged on one side of the aluminum substrate, corresponding to the LED lamp bead is smartly adopted, and the transparent light-transmitting lens is fully utilized to refract and reflect light emitted by the LED lamp bead for many times, thus effectively converging the light emitted by the LED lamp bead, fully improving the light utilization efficiency of the LED lamp bead, effectively enhancing the illumination effect of the LED ball lamp so as to be capable of improving the light brightness by more than 50% compared with the conventional LED ball lamp with same power, and further achieving the energy saving purpose. The LED ball lamp is simple in structure, safe, and strong in practicability.

Owner:蔡干强

Process for producing metallic translucent lens

InactiveCN101195196AEasy to process preciselyQuality improvementPicture framesDomestic mirrorsLaser technologyResource consumption

The invention a process for preparing metal light transmitting mirrors and relates to the process for preparing metal lens which have light transmitting effects. The process comprises selecting sheet metals for mirror faces, stamping the sheet metals into flat lens, using a shape-pressing die which is used to produce concave dies and convex dies to press invisible graph-texts on the positive surface of the lens or burn graph-texts on the negative surface of the lens through lasers, and producing the graph-texts which are same with the graph-texts on the positive surface of the lens on the negative surface of the lens or on carriers of the lens. The invention adopts mechanical moldings or laser techniques instead of handwork manufactures or casting techniques, the invention has the advantages that the manufacture of the light transmitting effects can be finished through forming by one step, the graph-texts can take various modes, the invention is convenient to manufacture precisely, the quality is stable, the imaging effect is clear, lens are light and durable, environmental pollution and resources consumption can be minimized, the lens can be combined with a plurality of carriers to produce different anti-counterfeit markings for jewelries, souvenirs, toys, teaching aids, handicrafts, commodities and the like, not only the graph-texts can be designed freely, but also image differences can be adjusted through adopting a laser technique, and the invention has strong randomness and wide applying range.

Owner:施近勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com