Method for detecting defects of 8-inch polished wafers through light-transmitting mirror

A technology of polishing sheet and light-transmitting mirror, which is applied in the direction of optical testing for flaws/defects, etc., to achieve high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

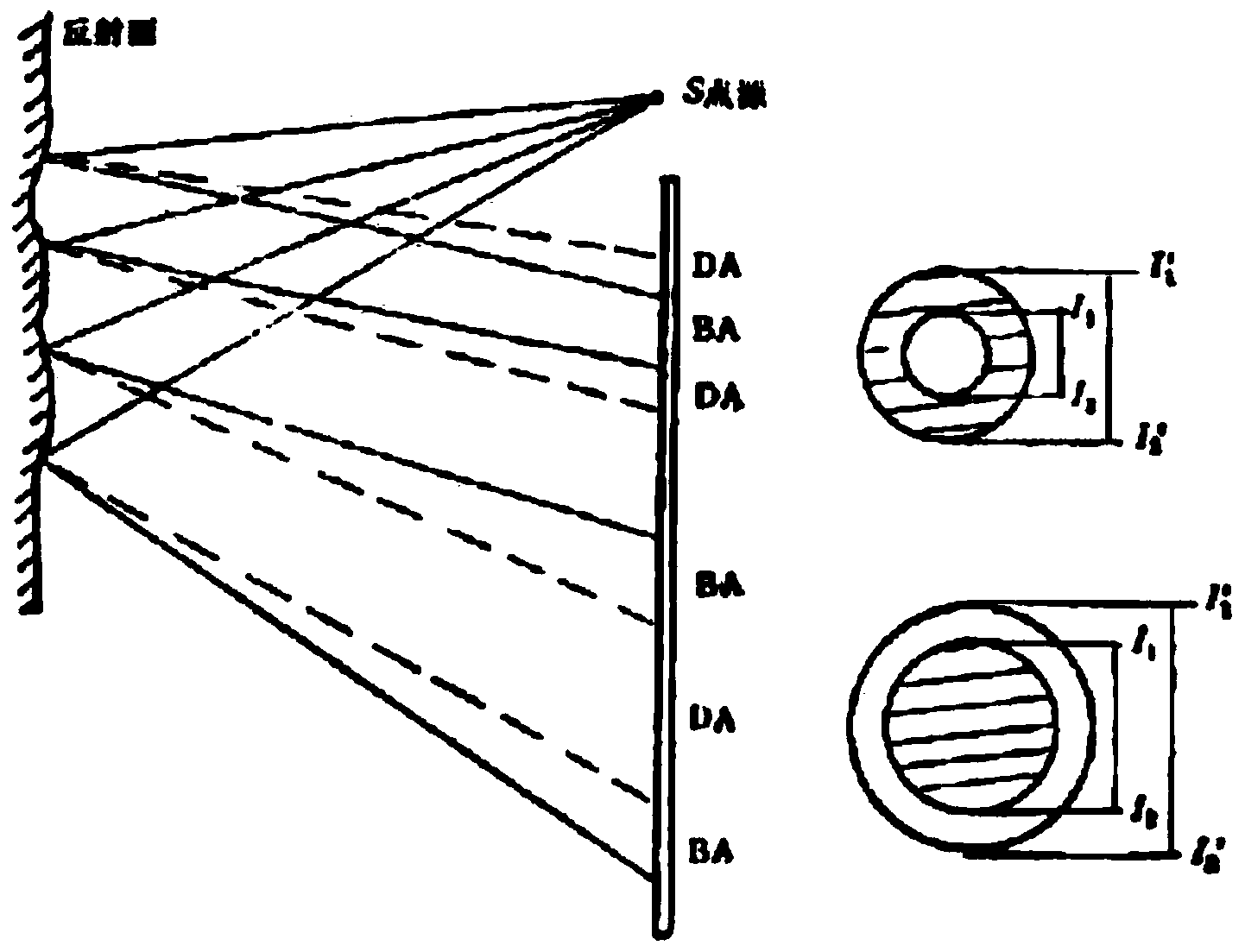

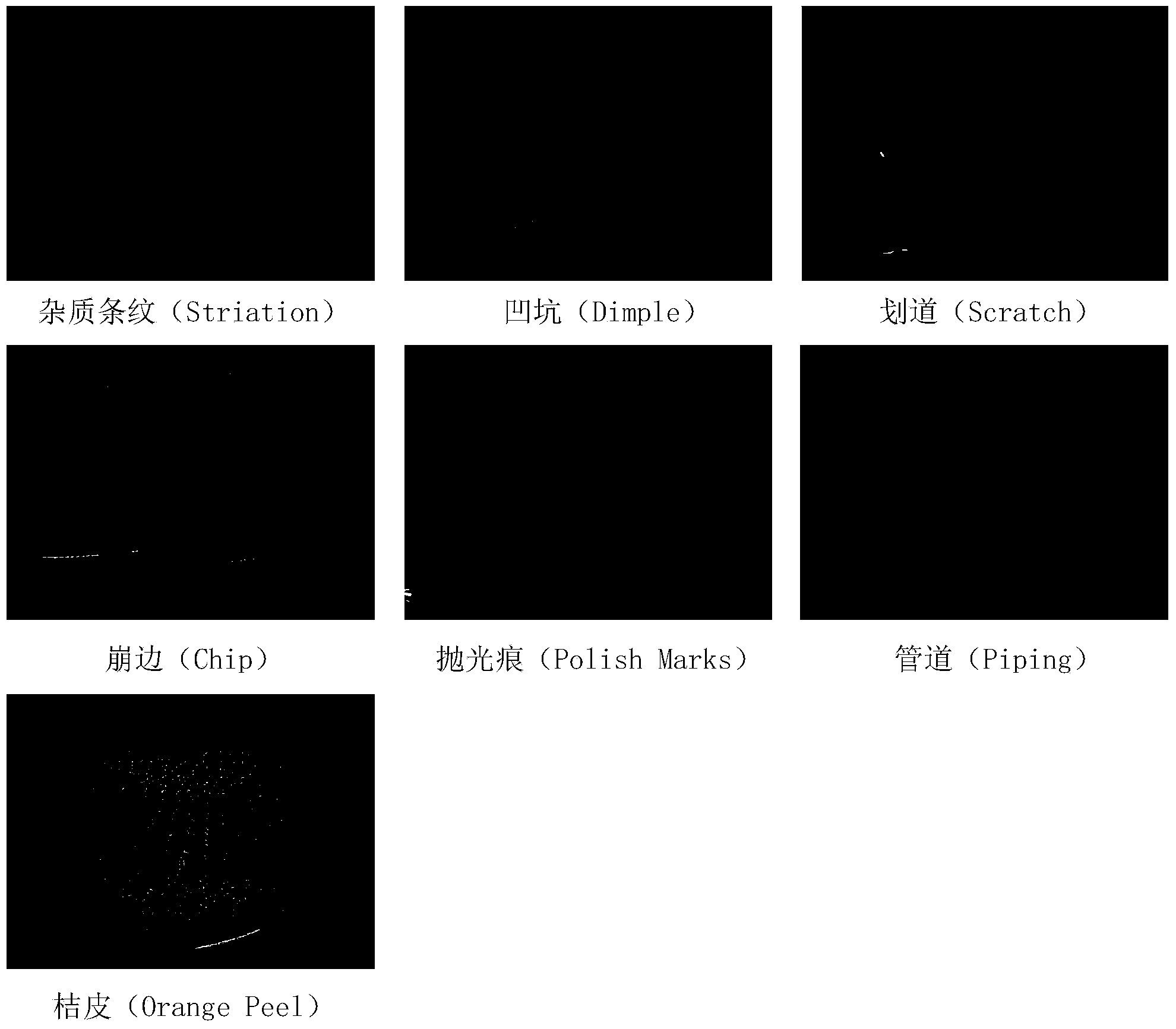

[0027] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] A method for detecting defects in 8-inch polished sheets with a light-transmitting mirror, the method uses a light-transmitting mirror to detect defects in 8-inch polished sheets, comprising the steps of:

[0029] (1) Turn on the total power input of the test system;

[0030] (2) Turn on the computer;

[0031] (3) Turn on the control box, press the light source power supply switch on the lighting power supply, observe the output ammeter at this time, the current value is 5.4-5.6A, if the displayed value exceeds this range, adjust the output current adjustment knob to adjust the current value to the specified value scope;

[0032] (4) Turn on the imaging display system;

[0033] (5) Turn on the wafer transfer system controller, and place the polished wafer to be tested on the wafer carrier;

[0034] (6) Select test parameters: sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com