Fluorescent powder performed thin film-based LED lamp and manufacturing method thereof

A technology for LED lighting and phosphors, applied in lighting devices, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of different light chromaticity, decreased luminous efficiency of phosphors, affecting LED life, etc. High degree of consistency and adjustability, convenience in size and phosphor content, and reduction in production processes and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

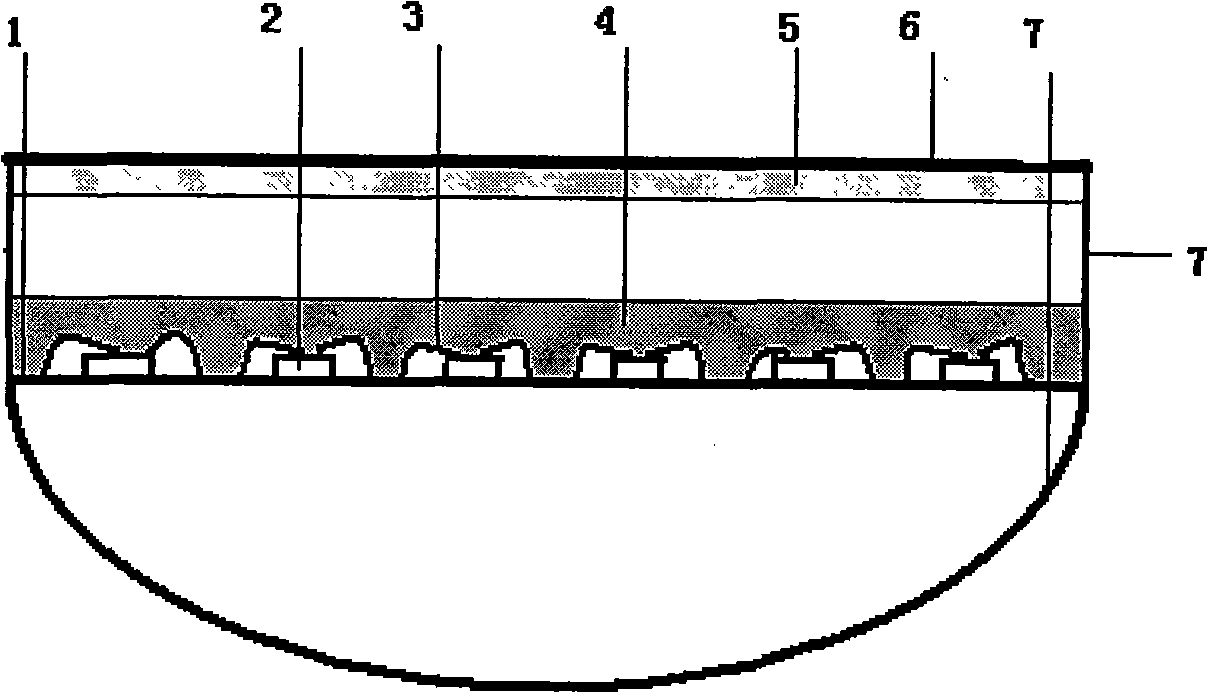

Embodiment 1

[0025] Weigh 2g of YAG fluorescent powder and 5g of silica gel, mix them evenly, apply a layer of 0.2mm thick film by screen printing method, put it in a vacuum dryer and heat and cure at 150°C for 30 minutes, take out the film and cut it into 20cm according to production requirements ×40cm film, apply a little silica gel on one side of the light-transmitting lens, then paste the cut film on it, put it in a vacuum desiccator and heat and cure at 150°C for 30 minutes, ready to use. Fix 20 chips on the metal substrate, connect the chips and the circuit on the metal substrate with gold wires, and keep the chips in parallel, and then coat a layer of silica gel on the metal substrate, so that the silica gel can connect the chips, gold The wire and the metal substrate are completely covered, and then the whole is put into a vacuum desiccator and solidified at 120°C for 1 hour. After cooling, the metal substrate is fixed in the lampshade, and then the light-transmitting lens with the ...

Embodiment 2

[0027] Weigh 5gYAG phosphor powder, 10gLiEuW 2 o 8 Phosphor powder and 20g epoxy resin, mix them evenly, apply a layer of 0.2mm thick film by screen printing method, put it into a vacuum dryer and heat and cure at 110°C for 30 minutes, take out the film and cut it into a certain size according to the production requirements Apply a little epoxy resin on one side of the light-transmitting mirror, then paste the cut film on it, put it in a vacuum desiccator and heat and cure it at 150°C for 20 minutes, and set it aside. Fix 50 chips on the metal substrate, connect the chips and the circuit on the metal substrate, and keep the chips in parallel, and then coat a layer of epoxy resin on the metal substrate, let the epoxy resin connect the chips, The gold wire and the metal substrate are completely covered, and then the whole is put into a vacuum desiccator and solidified at 100°C for 1 hour. After cooling, fix the metal substrate in the lampshade, and then install the light-transm...

Embodiment 3

[0029] Weigh 20gYAG phosphor powder, 10gSr 2 Si 2 N 8 :Eu 2+Fluorescent powder, 40g of silica gel, mix it evenly, apply a layer of 0.3mm thick film by screen printing method, put it in a vacuum dryer and heat and cure at 120°C for 60 minutes, take out the film and cut it into a film of a certain size according to the production requirements film, apply a little silica gel on one side of the light-transmitting mirror, and then paste the cut film on it, put it in a vacuum desiccator and heat and cure at 120°C for 30 minutes, ready to use. Fix 100 chips on the metal substrate, connect the chips and the circuit on the metal substrate, and keep the chips in parallel, and then coat a layer of silica gel on the metal substrate, so that the silica gel can connect the chips, gold wires, metal The substrate is completely covered, and then the whole is put into a vacuum desiccator and cured at 150°C for 1 hour. After cooling, fix the metal substrate in the lampshade, and then install ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com