LED display screen, full-color LED light-emitting panel and manufacturing method of full-color LED light-emitting panel

A technology of light-emitting panels and LED lights, which is applied in the direction of instruments, identification devices, etc., and can solve problems such as high processing temperature requirements, difficult maintenance of full-color LED light-emitting panels, and virtual soldering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

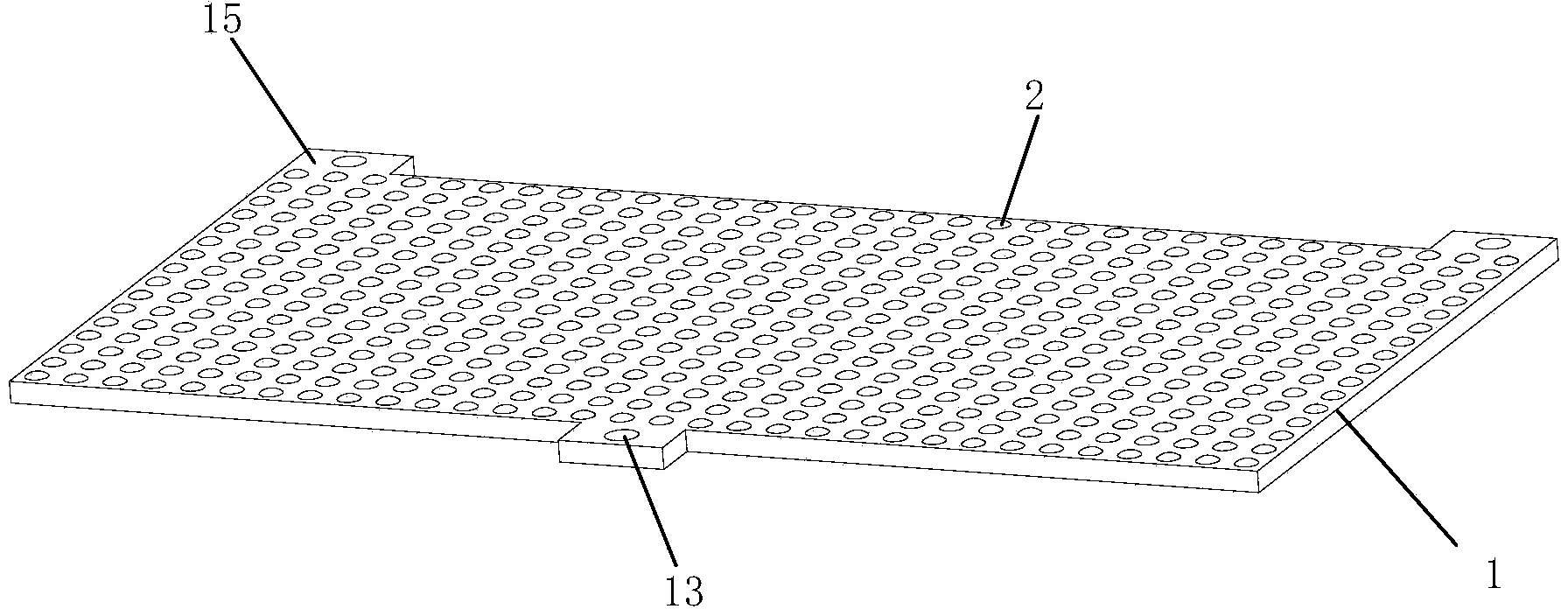

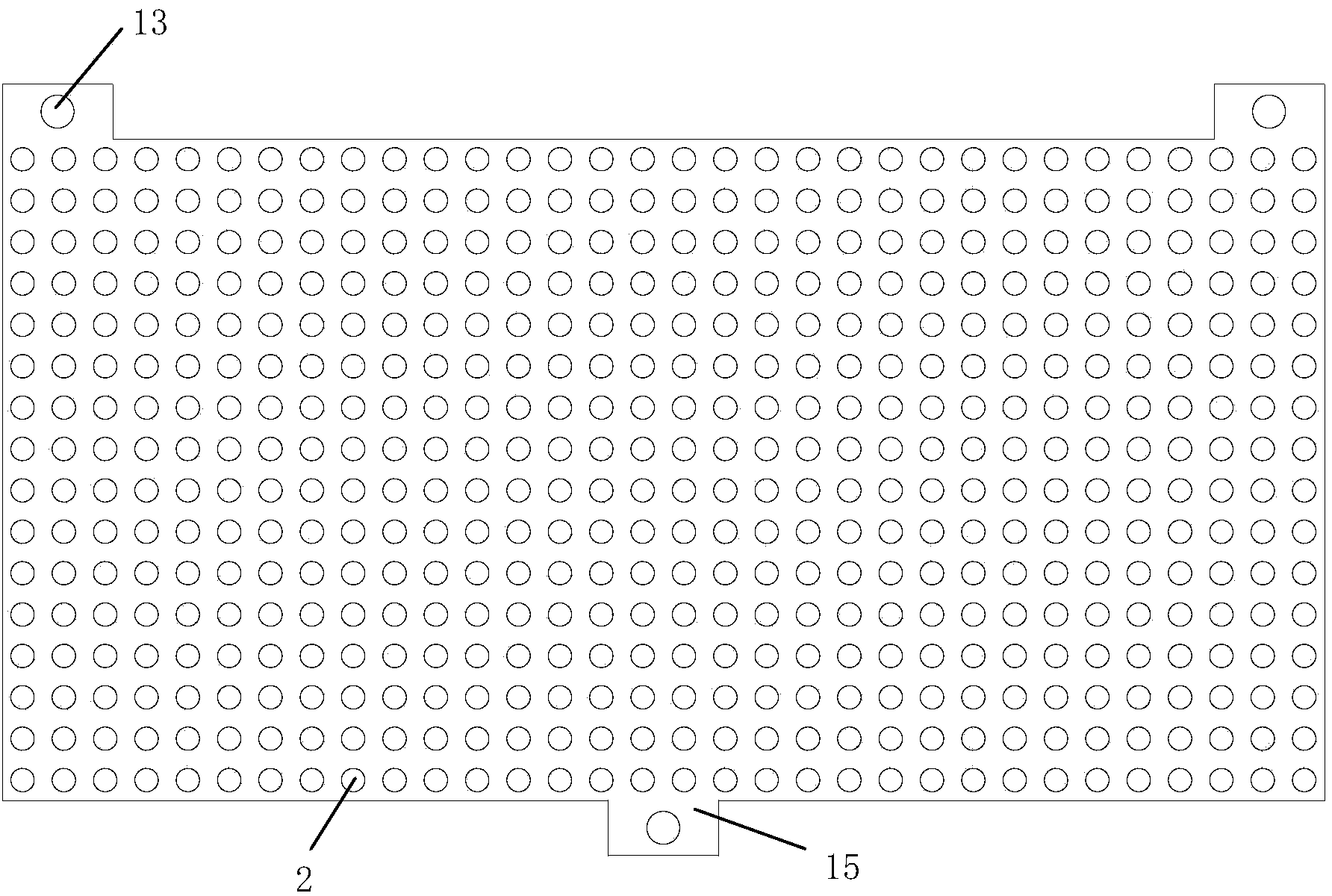

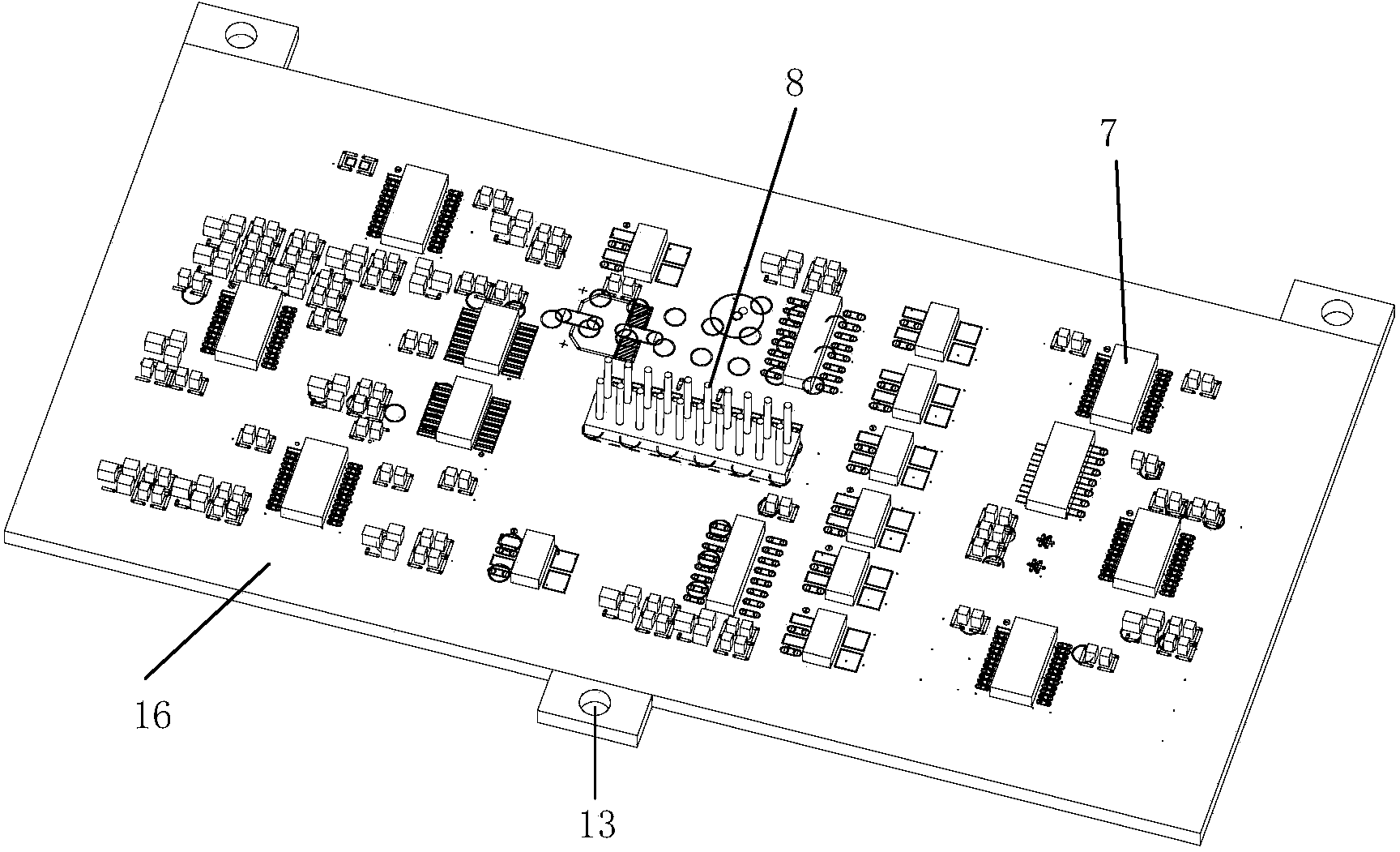

[0032] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0033] The invention provides an LED display screen, which has a full-color LED light-emitting panel. The full-color LED light-emitting panel includes a circuit board, an LED lamp array and a driving circuit arranged on the circuit board, and the circuit board is a printed circuit board, preferably a black core printed circuit board, which can also be Choose another PCB. The circuit board includes an opposite first surface and a second surface, the LED lamp array is arranged on the first surface of the circuit board, and the driving circuit is installed on the second surface of the circuit board; wherein, the An array of concave holes is formed on the first surface, and a plurality of immersion gold pads are provided at the bottom of each concave hole; the LED array is a full-color LED lamp array, and each full-color LED lamp is correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com