Heat-insulating light-penetrating device

A technology of light-transmitting devices and light-transmitting mirrors, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as blocking light, large dust and water mist, and affecting the service life of precision measurement components, so as to reduce the impact and improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

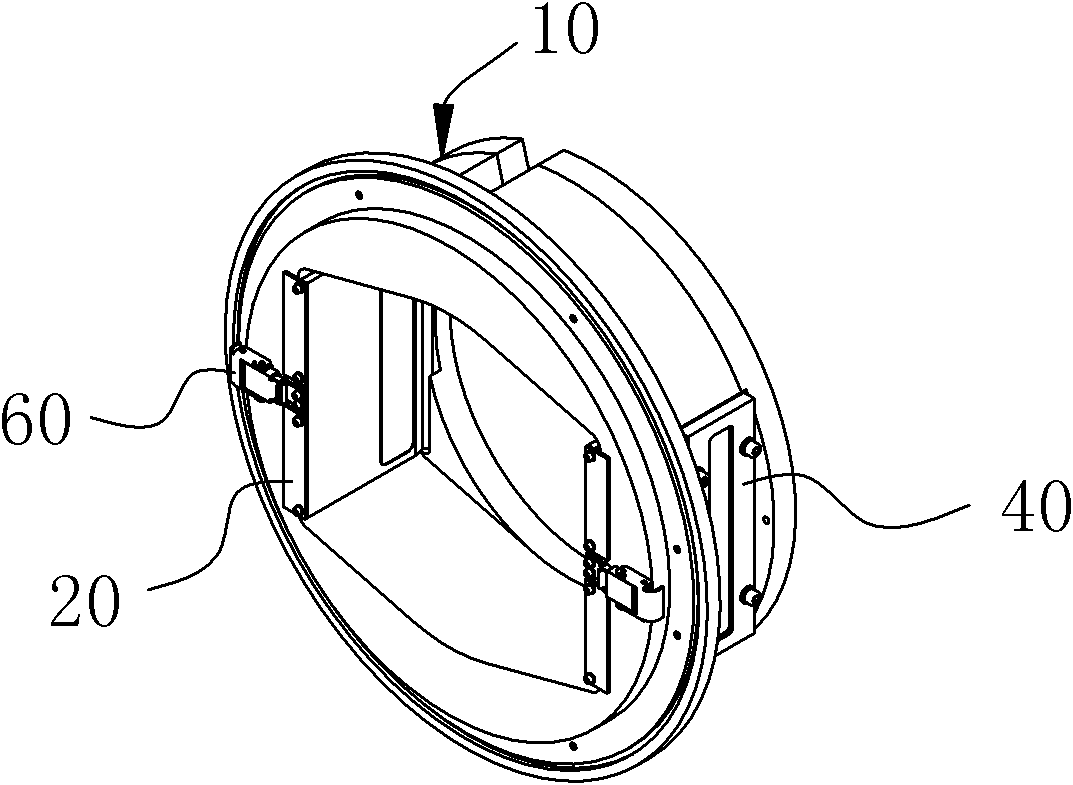

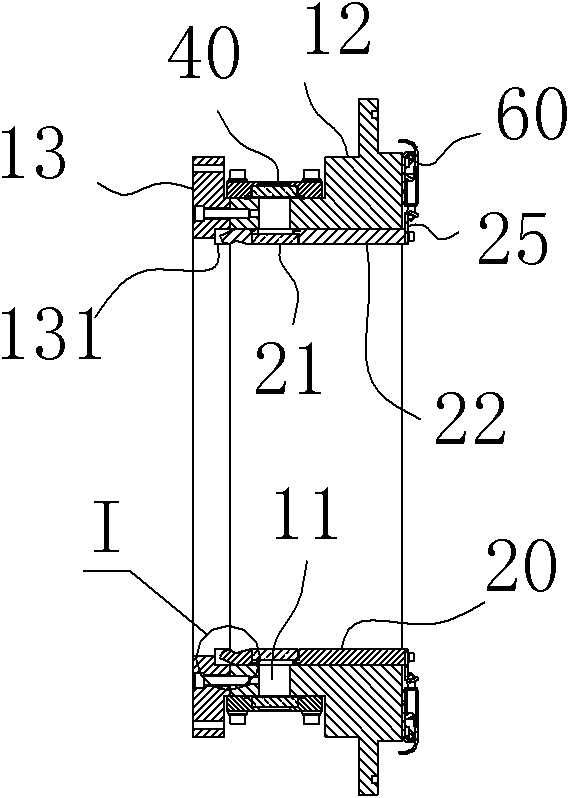

[0015] A heat-insulating and light-transmitting device, the shape of which is in the shape of a tube sleeve. The heat-insulating and light-transmitting device is symmetrically arranged on the tube wall along the line to be measured and the axis of the bar to allow radial transmission of the measuring light. Light-transmitting mirror 20, the mirror surfaces of the heat-insulating light-transmitting mirror 20 are parallel to each other and parallel to the direction of travel of the line to be measured and the bar, such as Figure 1-2 and Figure 4 shown.

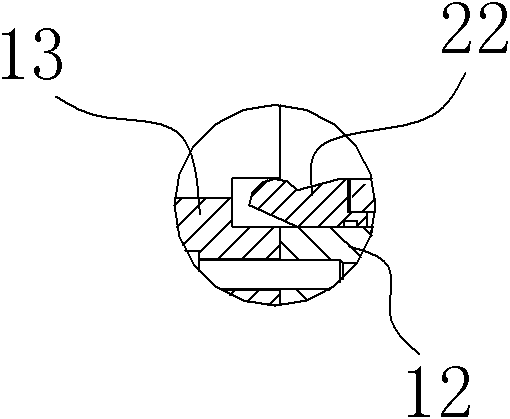

[0016] Further, in order to better realize the heat insulation and light transmission effect of the present invention, the heat insulation and light transmission device includes a base body 10, the base body 10 is in the shape of a tube sleeve, and the tube wall of the base body 10 is along the line to be measured, the bar The axis line is symmetrically provided with a through hole 11 radially penetrating through the tube wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com