LED down lamp

A technology of LED downlights and LED lamps, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of inconvenient installation and maintenance, shortening the service life of lamps, and poor anti-glare effect. Easy to process, save material, protect vision and eyesight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

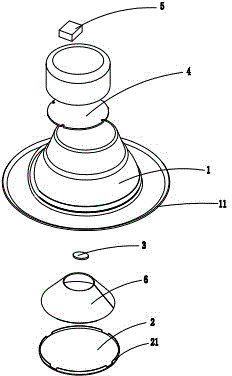

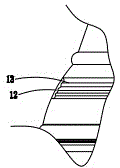

[0016] as attached Figure 1-2 As shown, an LED downlight includes a lamp body 1, a light-transmitting mirror 2, a reflector 6, an LED lamp 3, an aluminum substrate 4 and a driving power supply 5, and the light-transmitting mirror 2, the reflector 6 and the driving power supply 5 are respectively installed on On the lamp body 1, the LED lamp 3 is installed on the aluminum substrate 4, the aluminum substrate 4 is installed on the lamp body, and the driving power 5 drives the LED lamp 3 to work.

[0017] Wherein, the material of the lamp body 1 is aluminum, and the lamp body 1 is processed by spinning, and the bottom surface of the lamp body 1 is extended outwardly with a wing plate 11 for heat dissipation, and the wing plate 11 can be straight or inclined. The lamp body 1 is made of alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com