Lamp strip system capable of achieving large-area uniform light-emitting function

A technology of uniform light emission and area, applied in the field of automotive lighting, can solve the problem of no longer adapting to the rapidly changing modeling form, and achieve the effect of good light emission effect, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

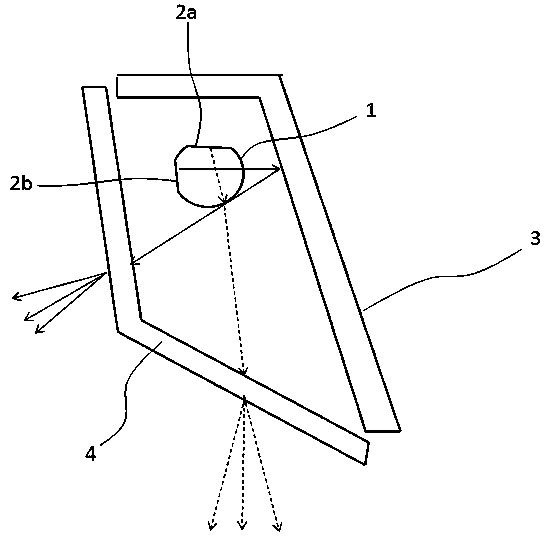

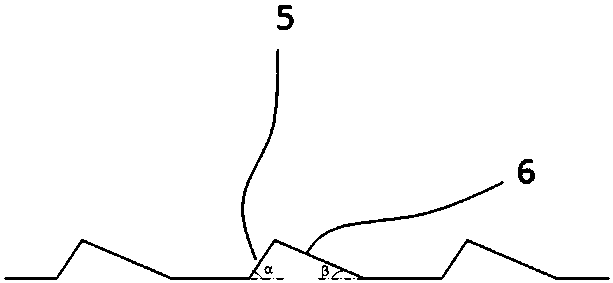

[0019] Such as Figure 1-2 As shown, this embodiment provides a light strip system that realizes large-area uniform light emission, including a light guide strip 1, a reflector 3 and an inner light-transmitting mirror 4, and the light guide strip 1 is located between the reflector 3 and the inner light-transmitting mirror 4. In the middle of the mirror 4, the light guide strip 1 is provided with two tooth-shaped optical patterns, that is, the first optical pattern 2a and the second optical pattern 2b. The tooth-shaped optical pattern 1 2a and the tooth-shaped optical pattern 2 2b are respectively Structure surface 1 5 and structure surface 2 6 are provided, and the included angle α and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com