Pre-packaged LED illuminating lamp and manufacture method thereof

A technology of LED lighting lamps and LED lamps, which is applied in the direction of lighting and heating equipment, lighting devices, chemical instruments and methods, etc., can solve the problems of decreased luminous efficiency of phosphor powder, incomplete luminous chromaticity, and affecting the life of LEDs, etc., to achieve It is convenient to control the size and phosphor content, ensure high consistency of performance, improve production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

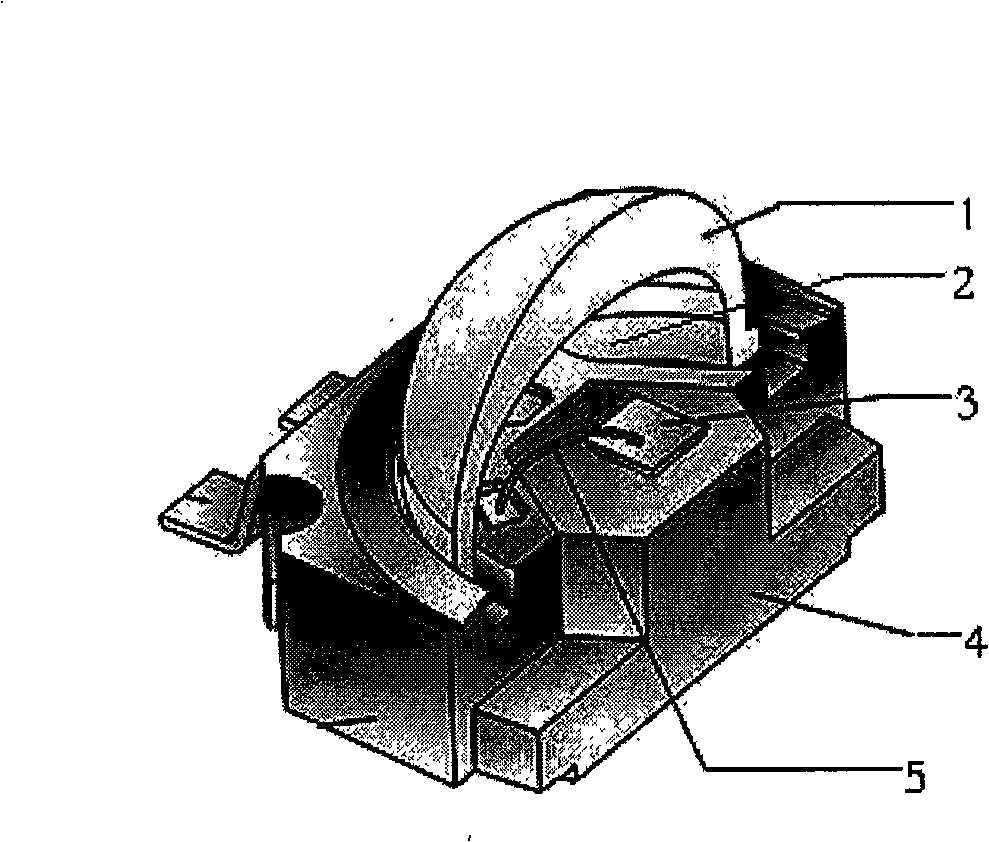

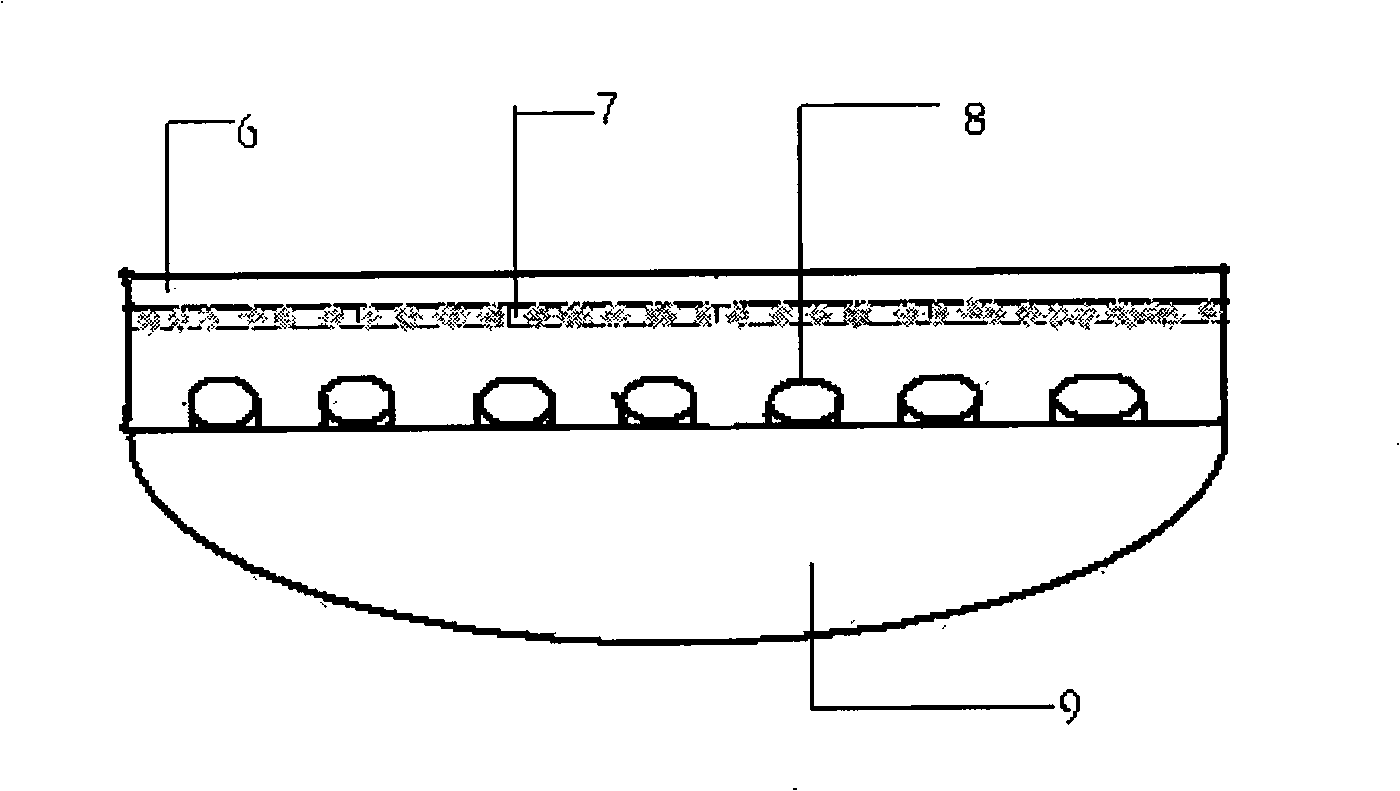

[0026] Example 1. Weigh 2g of YAG fluorescent powder and 5g of silica gel, mix them evenly, apply a layer of 0.2mm thick film by screen printing method, put it into a vacuum dryer and heat and cure at 150°C for 30 minutes, take out the film according to the production method It is required to cut into a film of a certain size, apply a little silica gel on one side of the light-transmitting lens, then paste the cut film on it, put it in a vacuum desiccator and heat and cure at 150°C for 30 minutes before use. Fix the chip on the bracket, solder the circuit, then cover the lens, inject silica gel into the gap in the middle, put it in a vacuum desiccator and heat and cure at 150°C for 1 hour, then fix 5 independent LED lights in the lampshade, and connect them well circuit, and finally the light-transmitting mirror pasted with phosphor powder and silicone film is fixed on the lampshade, and the side pasted with the film is fixed on the inside, thus manufacturing a pre-packaged LED...

Embodiment 2

[0027] Embodiment 2. Weigh 5gYAG fluorescent powder, 10gLiEuW 2 o 8 Phosphor powder and 20g epoxy resin, mix them evenly, apply a layer of 0.4mm thick film by screen printing method, put it in a vacuum dryer and heat and cure at 150°C for 60 minutes, take out the film and cut it into a certain size according to the production requirements Apply a little epoxy resin on one side of the light-transmitting mirror, then paste the cut film on it, put it in a vacuum desiccator and heat and cure it at 150°C for 10 minutes, and set it aside. Fix the chip on the bracket, solder the circuit, then cover the lens, inject silica gel into the gap in the middle, put it in a vacuum desiccator and heat and cure at 150°C for 1 hour, then fix 40 independent LEDs in the lampshade, and connect the circuit. Finally, the lens pasted with phosphor powder and epoxy resin film is fixed on the lampshade, and the side pasted with the film is fixed inside, thus a pre-packaged LED lighting lamp is manufact...

Embodiment 3

[0028] Embodiment 3. Weigh 20gYAG fluorescent powder, 10gSr 2 Si 2 N 8 :Eu 2+Fluorescent powder, 40g of silica gel, mix it evenly, apply a layer of 0.4mm thick film by screen printing method, put it in a vacuum dryer and heat and cure at 120°C for 120 minutes, take out the film and cut it into a film of a certain size according to the production requirements film, apply a little silica gel on one side of the light-transmitting mirror, and then paste the cut film on it, put it in a vacuum desiccator and heat and cure it at 150°C for 30 minutes, ready to use. Fix the chip on the bracket, solder the circuit, then cover the lens, inject silica gel into the gap in the middle, put it in a vacuum desiccator and heat and cure at 150°C for 1 hour, then fix 100 independent LEDs in the lampshade, and connect the circuit. Finally, fix the lens with the fluorescent powder and the silicone film on the lampshade, and fix the side with the film on the inside, so that the pre-packaged LED l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com