3D flame simulation system and electric fireplace

A simulation system and flame technology, applied in the field of 3D flame simulation system and electric fireplace, can solve the problems of high cost, complex structure, large volume, etc., and achieve the effect of high assembly efficiency, small volume, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described in conjunction with the following examples.

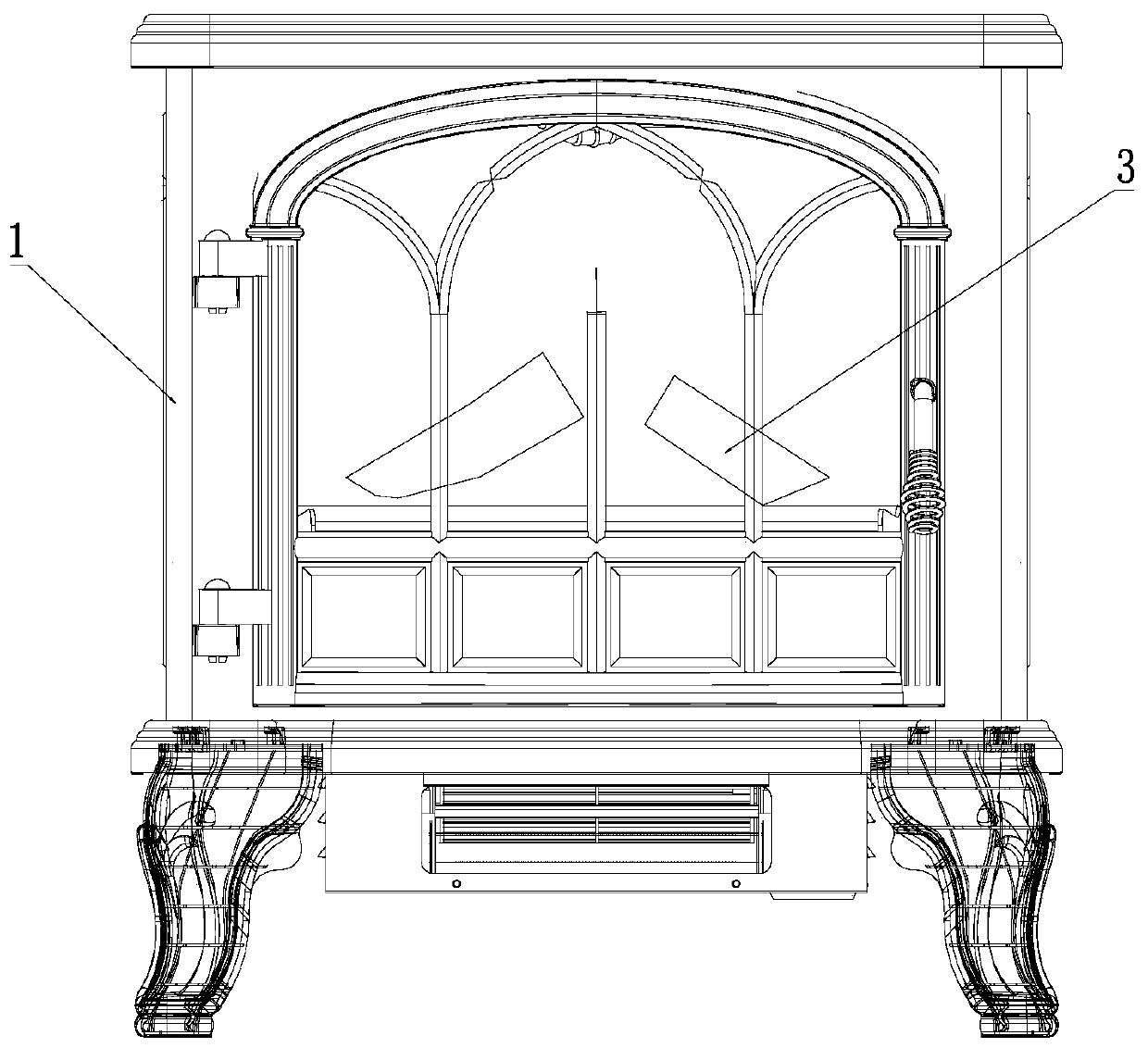

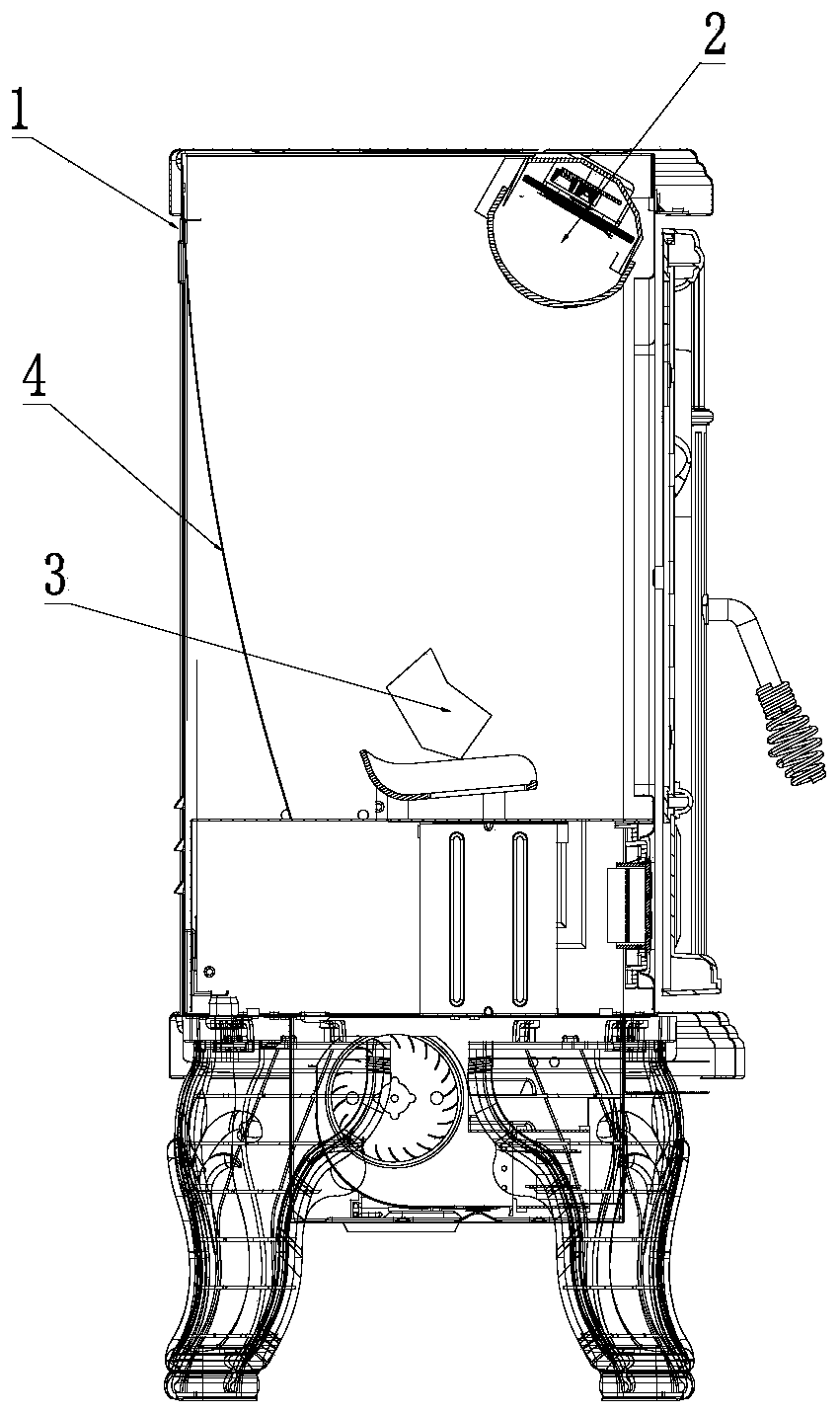

[0027] A kind of 3D flame simulation system of the present invention, it is installed in the middle box body 1 of electric fireplace, as figure 1 and figure 2 shown. The 3D flame simulation system includes a projection backplane 4, simulated charcoal 3 and a light source projection device 2. The light projected by the light source projection device 2 can be projected onto the projection backplane 4 and simulated charcoal 3, thereby forming a 3D flame effect. The light source projection device 2 is generally installed on the top or side top of the box body 1, and of course it can also be installed on the bottom or side of the box body 1. In this embodiment, as figure 2 As shown, the light source projection device 2 is installed on the side top of the box body 1 .

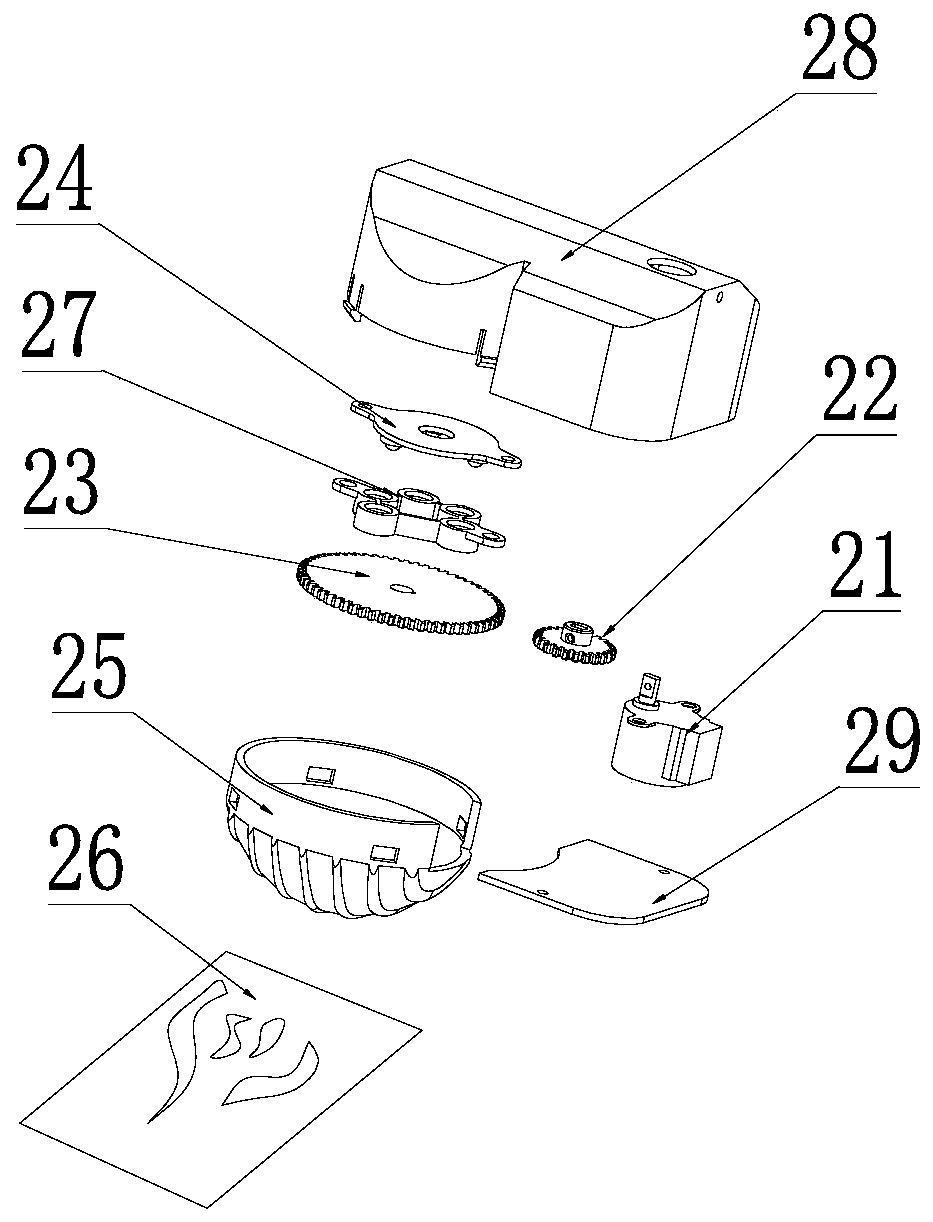

[0028] Such as image 3 and Figure 4 As shown, the light source projection device 2 includes an LED lamp board 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com